A Ring-by-Ring Lifting Installation Method of Suspension Dome Cable-strut System

An installation method and a technology for a dome with chord support, which can be applied to buildings and building structures, etc., can solve the problems of high crane performance requirements, high construction measures, and difficulty in deploying cables, so as to reduce the amount of work at heights and reduce requirements. The effect of working difficulty and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

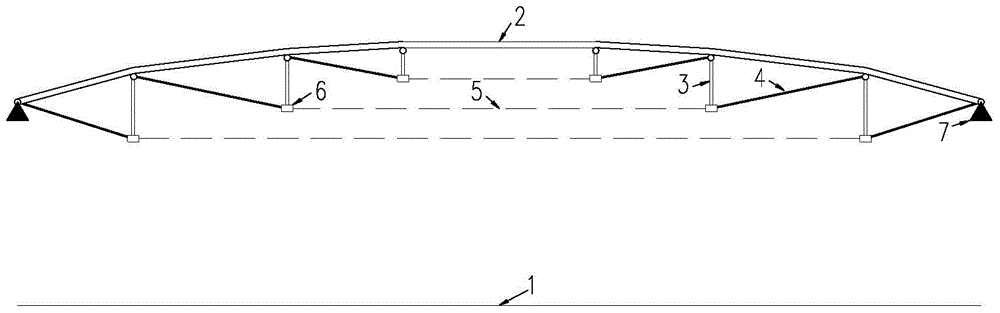

[0033] Such as figure 1 As shown, a kind of suspension dome cable-strut system of the present invention hoists and installs method ring by ring, comprising the following steps:

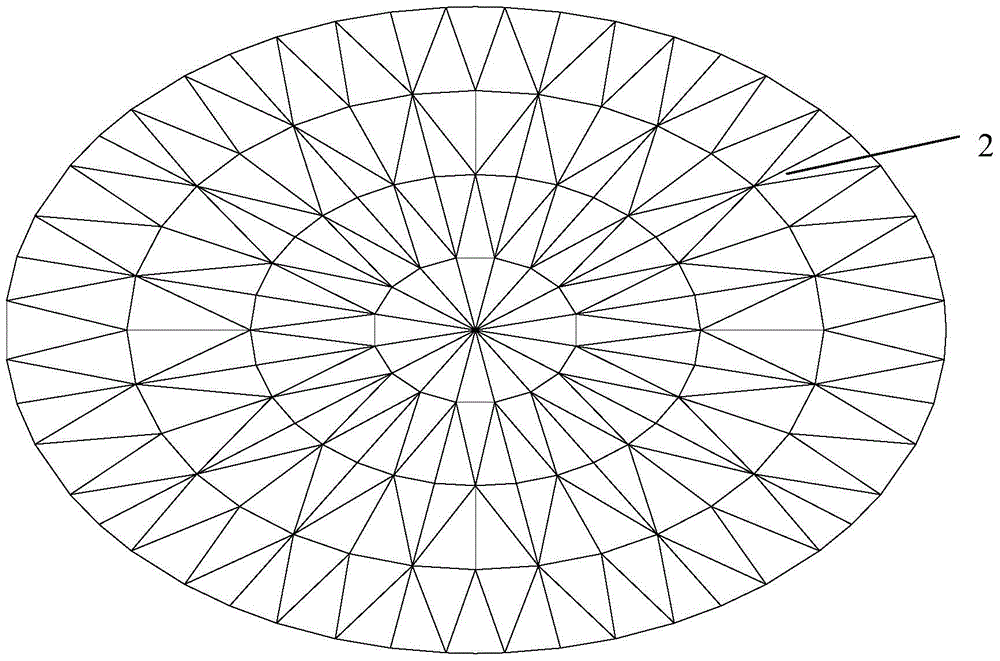

[0034] The first step: install the supporting tower 8 of the upper reticulated shell 2, hoist the upper reticulated shell 2 on the supporting tower 8 in pieces, and assemble to form the upper reticulated shell 2 as a whole; the upper reticulated shell 2 is equipped with connecting node. In the first step, the boundary of the assembled upper reticulated shell 2 is supported by the structural support 7 .

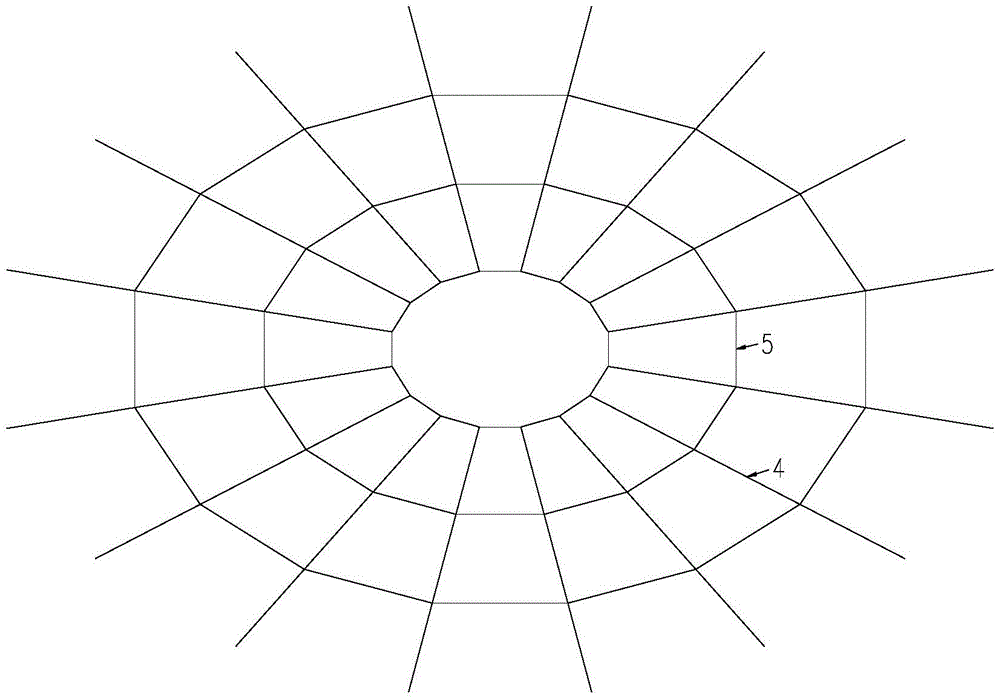

[0035] Step 2: Make the cables and transport them to the construction site, unfold the loop cables 5 on the projection ground 1 ring by ring, install the cable clips 6, the struts 3 and the oblique cables 4, and then use the tooling connector 9 to connect the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com