High-strength bamboo composite material movable house

A composite material and mobile house technology, applied in the field of mobile houses, can solve the problems of cumbersome installation steps, inconvenient transportation, inconsistent stiffness of joints, etc., and achieve the effects of improving material utilization, high structural use efficiency, and consistent overall stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

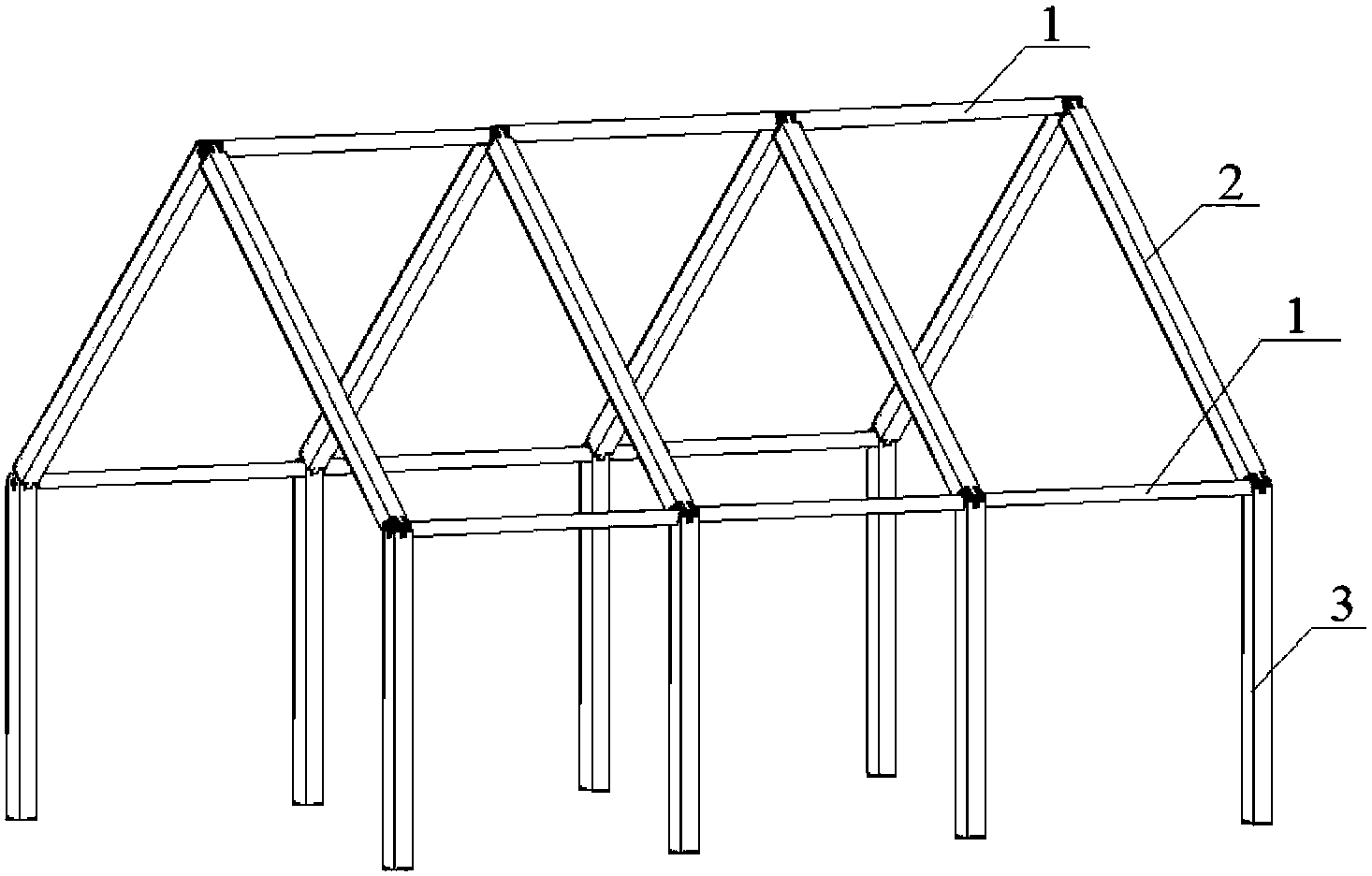

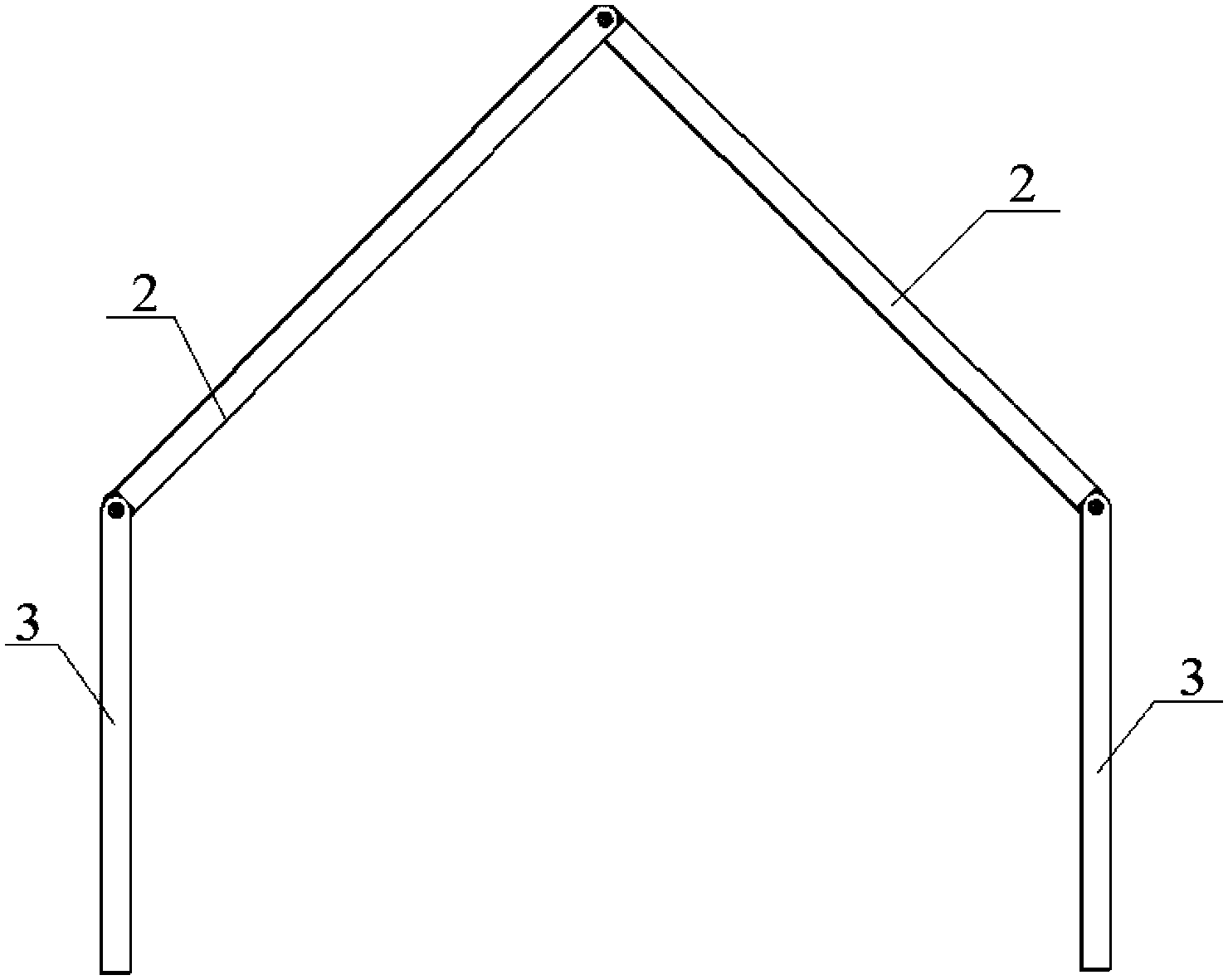

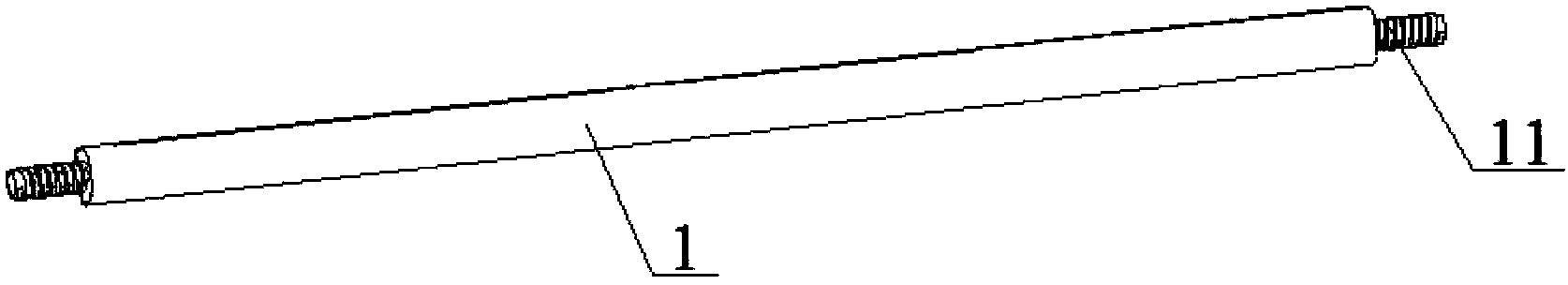

[0019] A high-strength bamboo composite prefabricated house includes a prefab frame and a covering layer laid on the prefab frame, and the covering layer is filled and paved outside the prefab frame according to usage requirements to form an enclosure for the entire structure. Activity room frame such as figure 1 , Figure 4 As shown, it consists of a plurality of single-frame frames arranged side by side and cross beams 1 connecting adjacent single-frame frames. A single framework such as figure 2 As shown, each single-frame frame is composed of two longitudinal beams 2 and two columns 3, the upper ends of the two longitudinal beams 2 are hinged by the cross beam 1, and the lower ends of the two longitudinal beams 2 are respectively connected by the cross beam 1 and the two vertically arranged The upper end of each column 3 is hinged. Such as image 3 As shown, the two ends of the beam 1 are threaded sections 11 respectively, and the threaded section 11 hinges the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com