Modular intelligent bridge expansion joint

A technology for expansion joints and bridges, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of accumulation of dust and debris, mutual interference of forces, fluctuations in bearing capacity, etc., to reduce the number of beams, strong adaptability, and volume. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

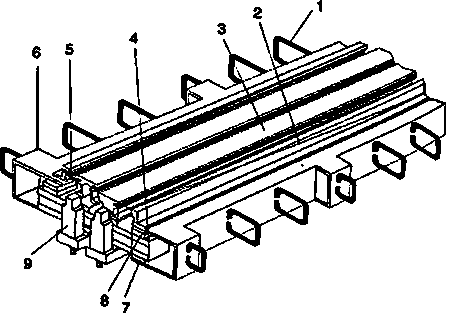

[0015] refer to figure 1 As shown, a modular intelligent bridge expansion joint includes anchor ribs 1, side beams 2, middle beams 3, beams 4, rubber sealing strips 5, displacement control boxes 6, pressure bearings 7, and compression bearings 8 And the hanger 9, the anchor bar 1 is welded on the side beam 2 to play the role of force transmission, the upper part of the side beam 2 is rigidly connected with the bridge, the lower part of the side beam 2 is provided with a crossbeam 4, and the lower part of the crossbeam 4 The main body is provided with a supporting hanger 9, and the lower edge is slidingly arranged in the displacement control box 6, and the middle beam 3 is supported by the cross beam 4 at its lower part, which is very beneficial to the large-displacement telescopic device, reduces the number of cross beams, and makes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com