Water-based environment-friendly cleaning agent for circuit boards

A cleaning agent and circuit board technology, which is applied in the direction of detergent compounding agent, detergent composition, non-ionic surface active compound, etc., can solve the problems of environmental pollution, high price, poor cleaning performance, etc., and achieves simple preparation method and easy cleaning The effect of reducing the number of times and stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

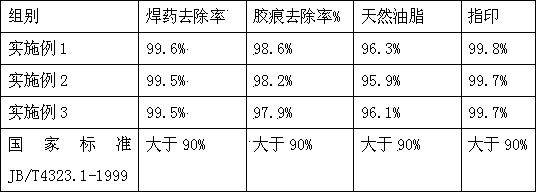

Examples

Embodiment 1

[0022] A circuit board cleaner, which is prepared from the following raw materials in parts by weight:

[0023] Potassium lauryl ether phosphate 1 part, sodium sulfate 1 part, tetrafluoropropanol 1 part, sodium citrate 1 part, benzotriazole 2 parts, isobutanol 3 parts, triethanolamine 3 parts, polyoxyethylene ether 3 parts, 4 parts of diethylene glycol monobutyl ether, 10 parts of coconut acid diethanolamide, 30 parts of deionized water;

[0024] The preparation method of this cleaning agent comprises the steps:

[0025] 1) Weigh each raw material according to the weight part for later use;

[0026] 2) Potassium lauryl ether phosphate, sodium sulfate, tetrafluoropropanol, sodium citrate, benzotriazole, isobutanol, triethanolamine, polyoxyethylene ether, diethylene glycol monobutyl ether and coconut oil Acid diethanolamide is put into the blender successively, and stirred at 200 rpm for 10 minutes to obtain the mixture;

[0027] 3) Discharge the mixture into the reaction tan...

Embodiment 2

[0030] A circuit board cleaner, which is prepared from the following raw materials in parts by weight:

[0031] Potassium lauryl ether phosphate 2 parts, sodium sulfate 2 parts, tetrafluoropropanol 2 parts, sodium citrate 2 parts, benzotriazole 3 parts, isobutanol 5 parts, triethanolamine 5 parts, polyoxyethylene ether 5 parts, 6 parts of diethylene glycol monobutyl ether, 15 parts of coconut acid diethanolamide, 40 parts of deionized water;

[0032] The preparation method of this cleaning agent comprises the steps:

[0033] 1) Weigh each raw material according to the weight part for later use;

[0034] 2) Potassium lauryl ether phosphate, sodium sulfate, tetrafluoropropanol, sodium citrate, benzotriazole, isobutanol, triethanolamine, polyoxyethylene ether, diethylene glycol monobutyl ether and coconut oil Acid diethanolamide is dropped into the mixer successively, and stirred at 200 rpm for 15 minutes to obtain the mixture;

[0035] 3) Discharge the mixture into the reacti...

Embodiment 3

[0037] A circuit board cleaner, which is prepared from the following raw materials in parts by weight:

[0038] Potassium lauryl ether phosphate 1 part, sodium sulfate 2 parts, tetrafluoropropanol 2 parts, sodium citrate 2 parts, benzotriazole 3 parts, isobutanol 3 parts, triethanolamine 5 parts, polyoxyethylene ether 5 parts, 6 parts of diethylene glycol monobutyl ether, 12 parts of coconut acid diethanolamide, 35 parts of deionized water;

[0039] The preparation method of this cleaning agent comprises the steps:

[0040] 1) Weigh each raw material according to the weight part for later use;

[0041] 2) Potassium lauryl ether phosphate, sodium sulfate, tetrafluoropropanol, sodium citrate, benzotriazole, isobutanol, triethanolamine, polyoxyethylene ether, diethylene glycol monobutyl ether and coconut oil Acid diethanolamide is dropped into the mixer successively, and 200 revs / min stirs and obtains mixture in 12 minutes;

[0042] 3) Discharge the mixture into the reaction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com