Up-conversion nano-material NaYbF4: Tm and preparation method thereof

A technology of nanomaterials and containers, which is applied in the field of preparation of upconversion nanomaterials, can solve problems such as poor dispersion, weak blue-violet light intensity, and uneven shape and size, and achieve high repeatability and high ratio effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

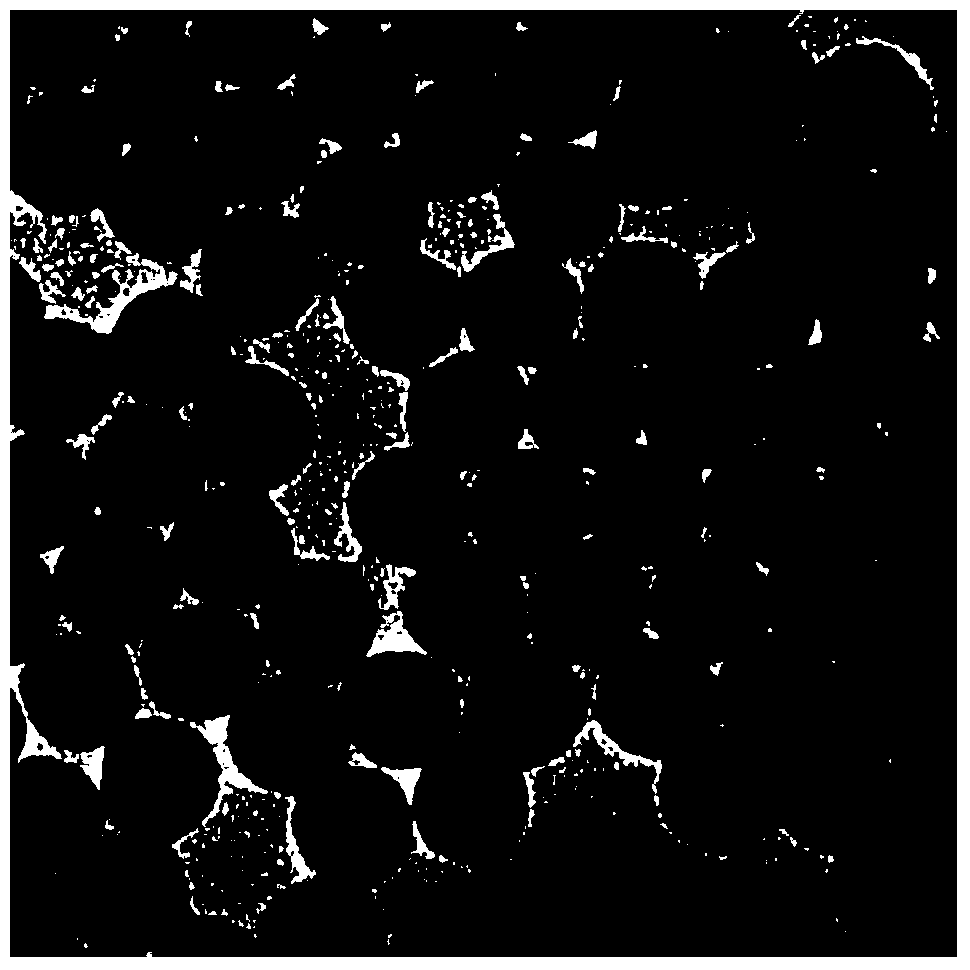

[0025] see figure 1 , an upconversion nanomaterial NaYbF 4 : The preparation method of Tm, comprises the following steps:

[0026] Step S101: adding Yb oleic acid complex and Tm oleic acid complex:

[0027] In the container according to the stoichiometric ratio Yb:Tm is 95-99.8:0.2-5, add the solution of Yb oleic acid complex and the solution of Tm oleic acid complex, so that the amount of Yb and Tm reaches 1 mmol;

[0028] Step S102: adding oleic acid and 1-octadecene:

[0029] Add oleic acid and 1-octadecene to the container respectively, so that the total volume of oleic acid reaches 6-10ml, and the total volume of 1-octadecene reaches 10-15ml;

[0030] Step S103: Add NH 4 F and NaOH:

[0031] Add 4~7mmol NH to the container respectively 4 F and 1 ~ 3.5mmol NaOH;

[0032] Step S104: vacuuming:

[0033] Vacuum the container to remove oxygen and moisture in the container;

[0034] Step S105: heating up:

[0035] Then heat the container to the first temperature thres...

Embodiment 1

[0070] The preparation method of the present invention uses RE oleic acid complex as a reactant, and the specific preparation method is as follows:

[0071] Synthesis of a solution of 1 mmol of Yb oleic acid complex (Yb-oleate):

[0072] (1) According to the stoichiometric ratio Yb:sodium oleate=1:3, weigh Yb(NO 3 ) 3 ·6H 2 O and sodium oleate;

[0073] ⑵According to the ratio of sodium oleate: cyclohexane: secondary water: absolute ethanol is 6 (mmol): 7 (ml): 3 (ml): 4 (ml), give Yb (NO 3 ) 3 ·6H 2 Add cyclohexane, secondary water and absolute ethanol in the mixture of O and sodium oleate;

[0074] (3) Stir continuously for 24 hours in a sealed container at room temperature;

[0075] (4) Use a separatory funnel to stand for stratification, separate, discard the lower liquid and keep the upper liquid, add ethanol: water = 1:1 (volume ratio) to the upper liquid to clean, and let it stand for stratification again. Placement, separation and cleaning were repeated three t...

Embodiment 2

[0088] Synthesis of a solution of 1 mmol of Yb oleic acid complex (Yb-oleate):

[0089] (1) According to the stoichiometric ratio Yb:sodium oleate=1:4, weigh Yb(NO 3 ) 3 ·6H 2 O and sodium oleate;

[0090] ⑵According to the ratio of sodium oleate: cyclohexane: secondary water: absolute ethanol is 6 (mmol): 14 (ml): 2 (ml): 8 (ml), give Yb (NO 3 ) 3 ·6H 2 Add cyclohexane, secondary water and absolute ethanol in the mixture of O and sodium oleate;

[0091] (3) Stir continuously for 12 hours in a sealed container at room temperature;

[0092] (4) Use a separatory funnel to stand for stratification, separate, discard the lower liquid and keep the upper liquid, add ethanol: water = 1:0.5 (volume ratio) to the upper liquid to clean, and let it stand for stratification again. Placement, separation and cleaning were repeated twice;

[0093] (5) Pour the cleaned upper liquid into a single-necked flask, and rotate it at 60°C until cyclohexane, water and ethanol are all removed to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com