Flexible screw claw tool, visual guidance covering device and covering method

A cap screwing claw and flexible technology, applied in the field of automatic cap closing devices, can solve the problems of low cap closing efficiency, human hazards, and low degree of automation, so as to improve labor production efficiency, increase the degree of automation, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention provides a quick-change structure and quick-change method for simultaneously replacing the material hose and the charging gun. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

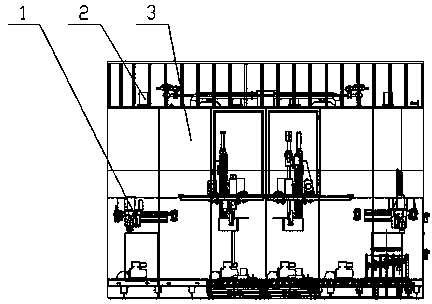

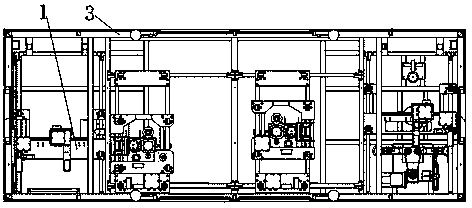

[0023] Such as figure 1 The visual addressing device 2 is fixed on the top 3 of the body. When the standard 200L material barrel runs to the working area of the lid closing mechanism 1 after filling, the visual addressing device 2 can capture enough images to analyze and determine the lid and the position of the barrel mouth.

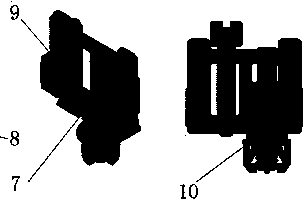

[0024] The lid closing mechanism 1 is fixed to the body 3, the two-dimensional walking trolley 5 is installed on the lid closing mechanism 1, and the flexible cap claw 4 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com