Novel structural non-stacking package box

A new type of structure and packaging box technology, applied in the field of non-stacking packaging boxes, can solve the problems of insufficient safety factor of packaging, material waste, economic loss, etc., and achieve simple structure, high reuse rate, and packaging cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

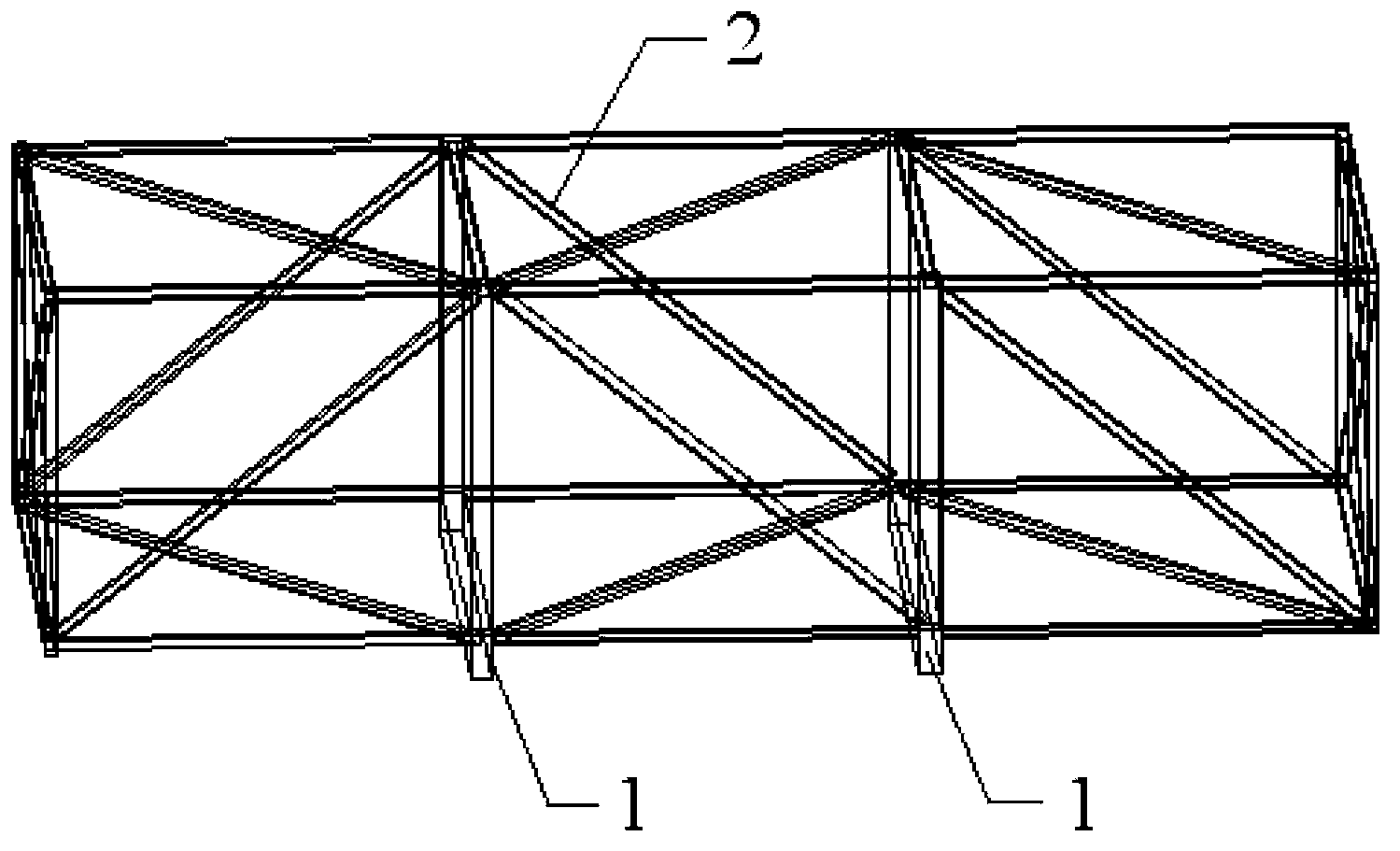

[0019] A new type of non-stacking packaging box, the structure of which is as follows figure 1 As shown, the packaging box is composed of two load-bearing main beams 1 and structural secondary beams 2. The section of the main load-bearing beam 1 is larger to carry the load of the packaged products, and the section of the structural secondary beam 2 is smaller than the section of the main load-bearing beam 1. The structural secondary beam 2 constitutes a truss-like structure to form the outer shell of the packaging box. The load-bearing main beam 1 used is a movable main beam, and the distance between the two load-bearing main beams 1 is determined according to the position of the center of gravity of the packaged product. The load-bearing main beam 1 is flexibly connected to the outer shell of the packaging box composed of secondary beams through the frame. superior.

[0020] The present invention abandons the structural form of the traditional packing box base sleepers pad s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com