Gravity self-locking hook structure

A self-locking, gravity technology, applied in the direction of passenger space, rack configuration, etc., can solve the problems of cumbersome, time-consuming and cost-intensive assembly operations, and insufficient convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to achieve the above-mentioned purpose and effect, the technical means and the structure adopted by the present invention are hereby illustrated in detail with respect to the preferred embodiments of the present invention. Its structure and function are as follows, in order to fully understand.

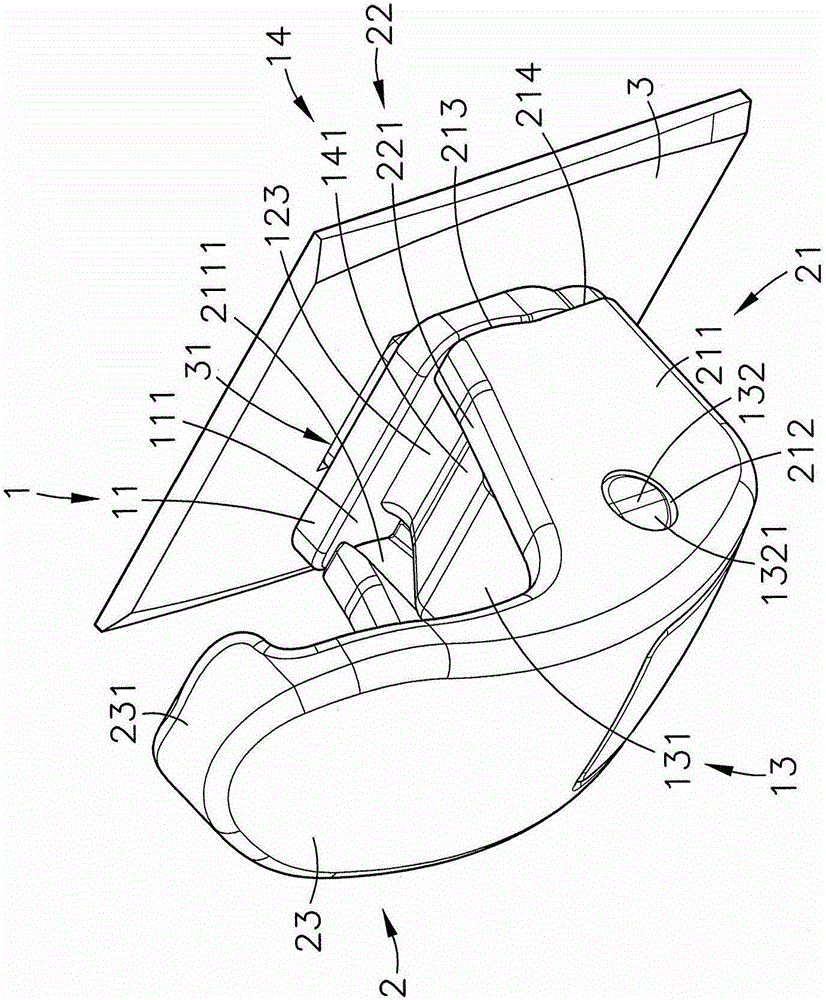

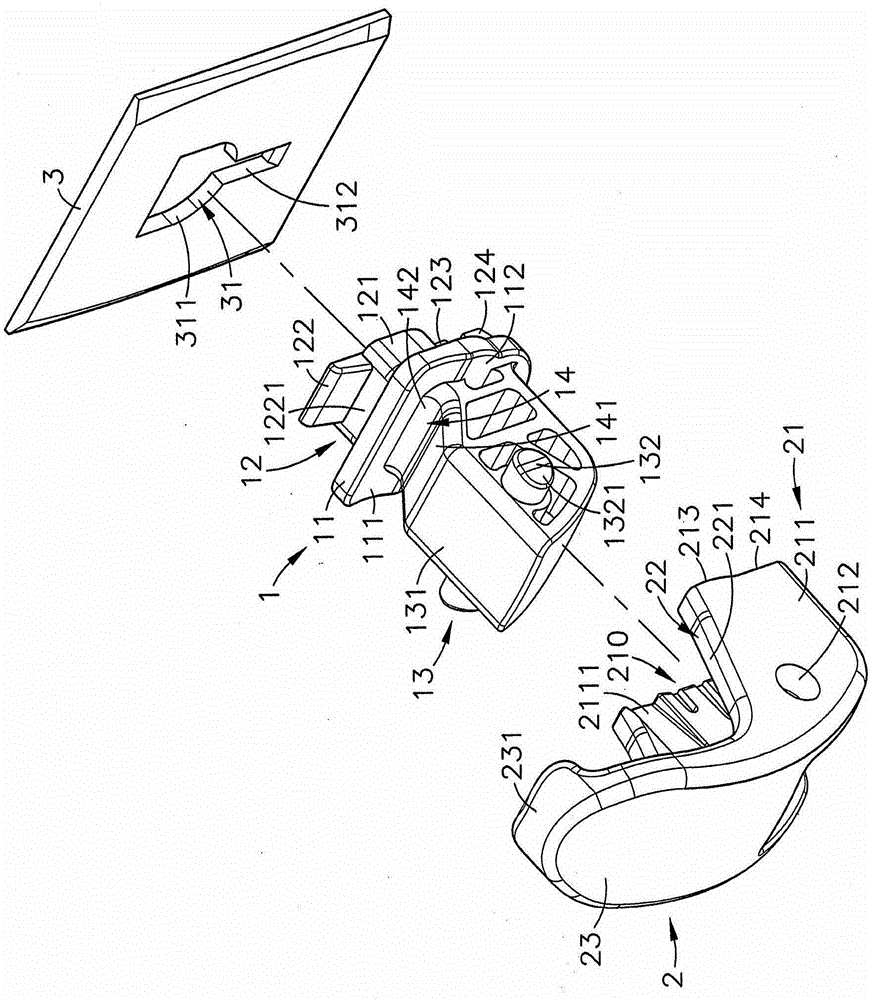

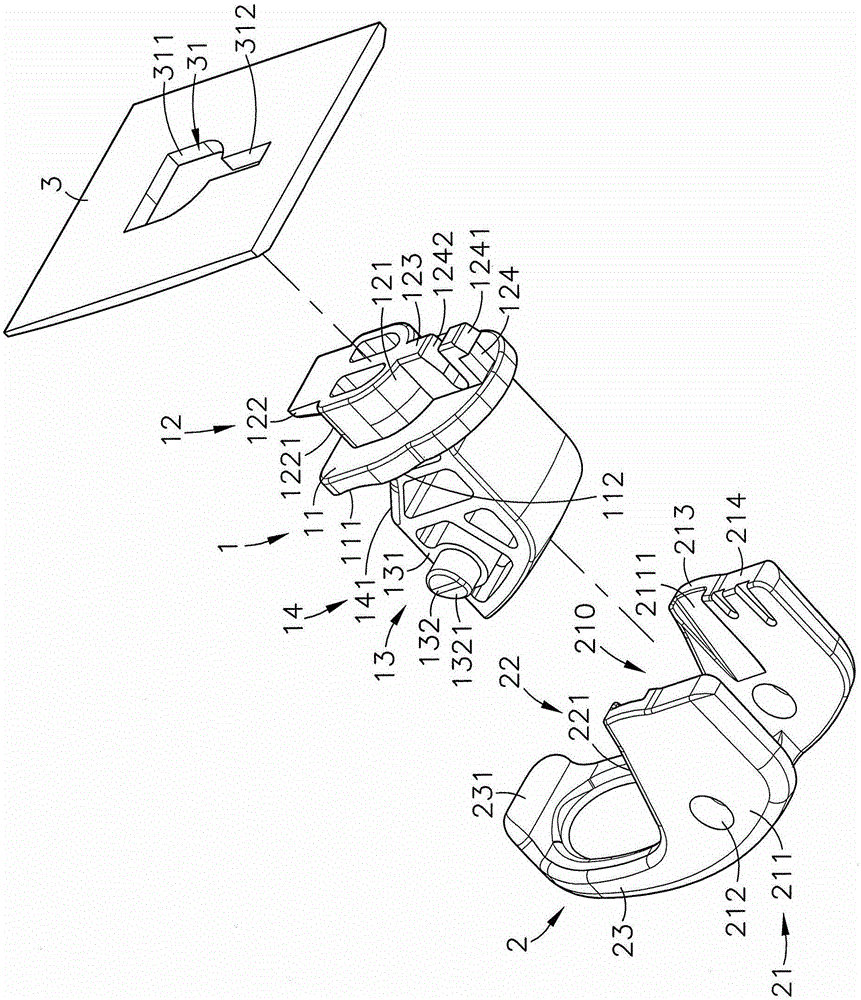

[0035] see figure 1 , figure 2 , image 3 , Figure 4 As shown, they are the three-dimensional appearance diagram, the three-dimensional exploded view, the three-dimensional exploded view and the three-dimensional sectional view of the present invention respectively. It can be clearly seen from the figure that the present invention includes the connecting seat 1, the hooking body 2 and the plate Body 3, so the main components and features of the present invention are described in detail as follows, wherein:

[0036] The connection seat 1 has a vertical base 11, and a positioning part 12 is provided at the rear of one side of the base 11. The positioning part 12 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com