Potato slicer

A slicer and potato technology, applied in metal processing, etc., can solve the problems of low production efficiency, waste of time and labor, and irregular shape of potatoes by manual slicing, and achieve the effects of simple structure, reduced labor cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

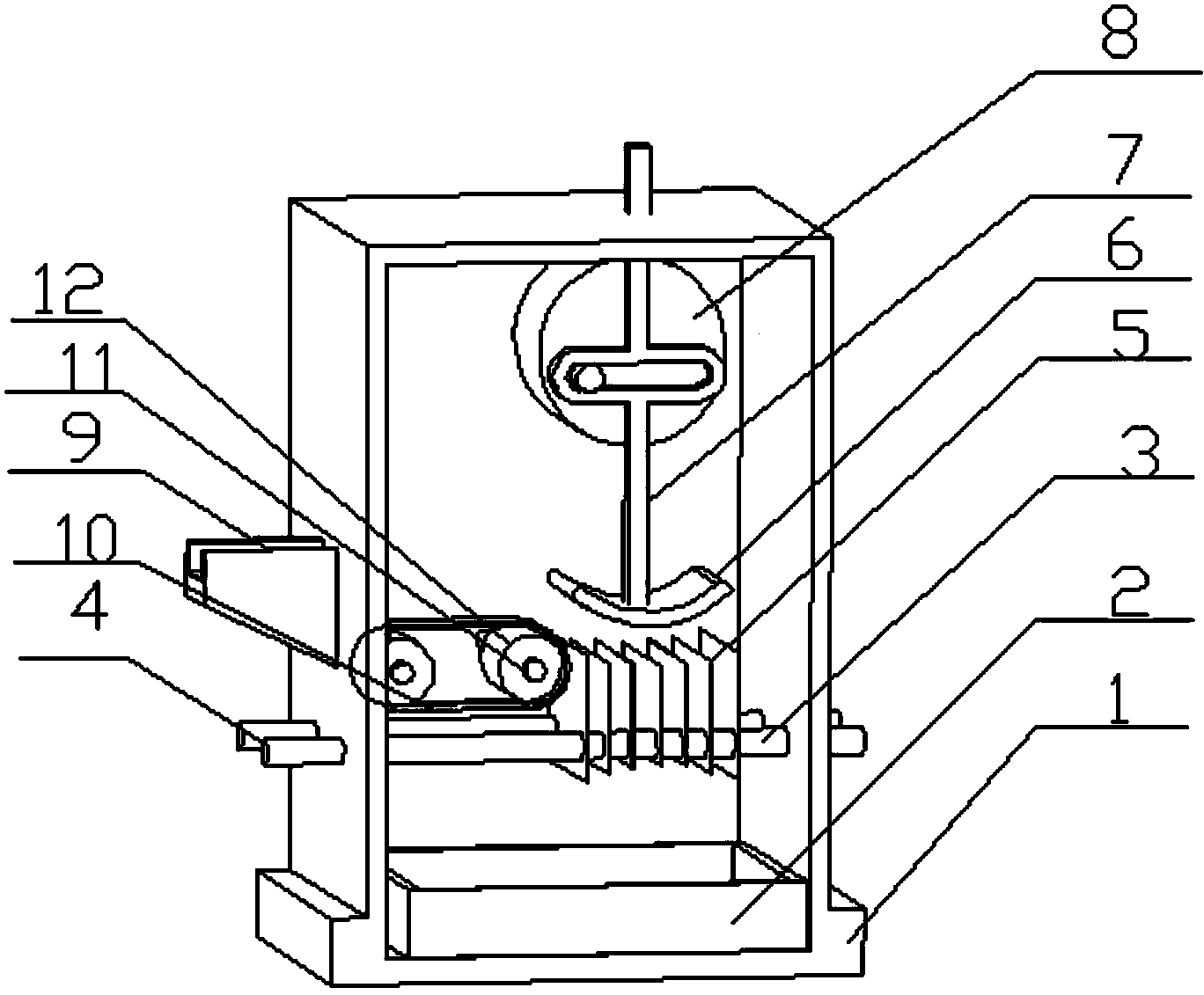

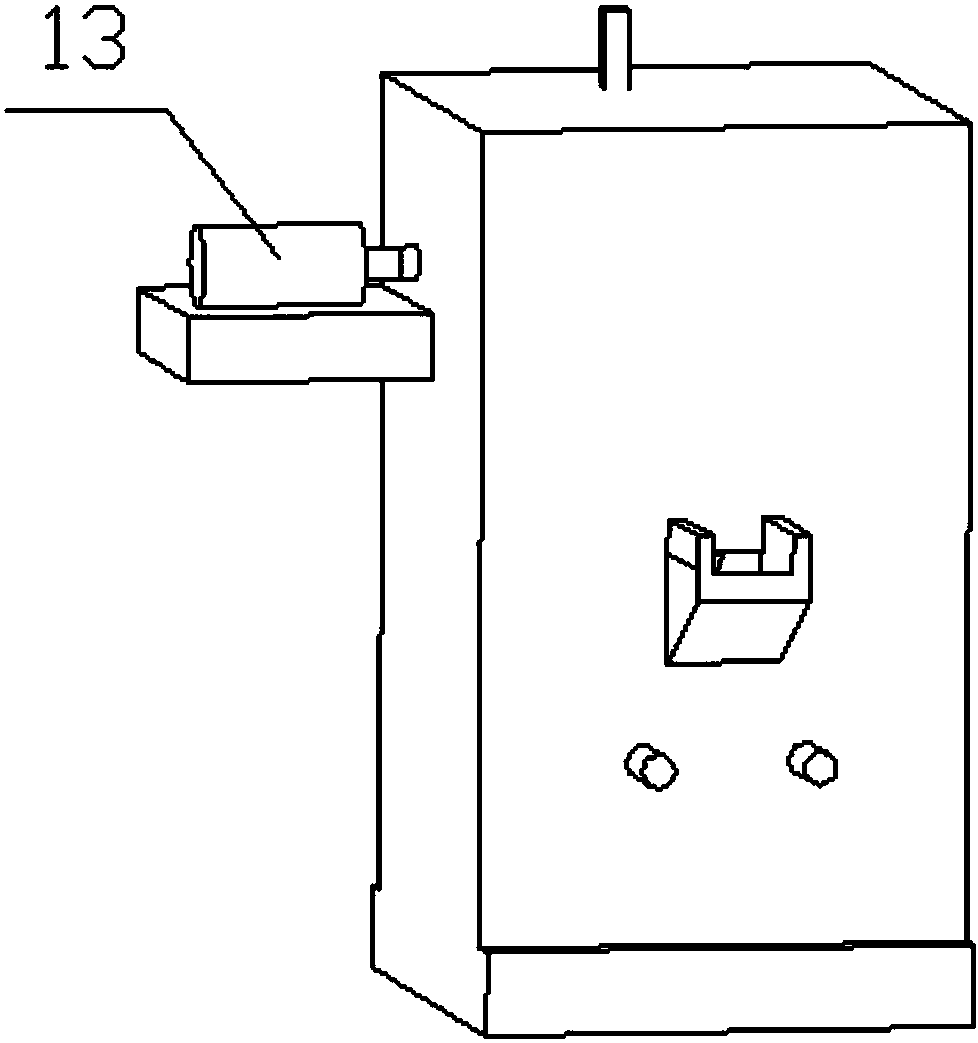

[0009] As shown in the figure, a potato slicer is composed of a box body 1, a tray 2, a cylindrical rod 3, a threaded rod 4, a blade 5, a push piece 6, a push rod 7, a disc 8, a transmission channel 9, and a conveyor belt 10. , conveyor pulley 11, conveyor pulley rod 12, and motor 13. It is characterized in that: threaded rod 4 is installed on the wall of box 1, blade 5 is connected in threaded groove of threaded rod 4, and threaded rod 4 has opposite threads on both sides. , the threaded rod 4 can move left and right along the box body, the cylindrical rod 3 and the threaded rod 4 are installed on the box body 1 in parallel, the rotating disc 8 is installed on the inner side wall at the rear of the box body, and is connected with the push rod 7 through the pin on the disc , the end of the push rod is connected with the push piece 6 by bolts, the motor 13 is connected with the disc 8, and installed behind the outer side of the box 1, the loading plate 2 is placed at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com