Manipulator device for motor stator assembly

A motor stator and manipulator technology, applied in the field of manipulators, can solve the problems of unbalanced lifting, damage, safety hazards, etc., and achieve the effects of improving work efficiency, convenient and flexible operation, and reducing labor load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

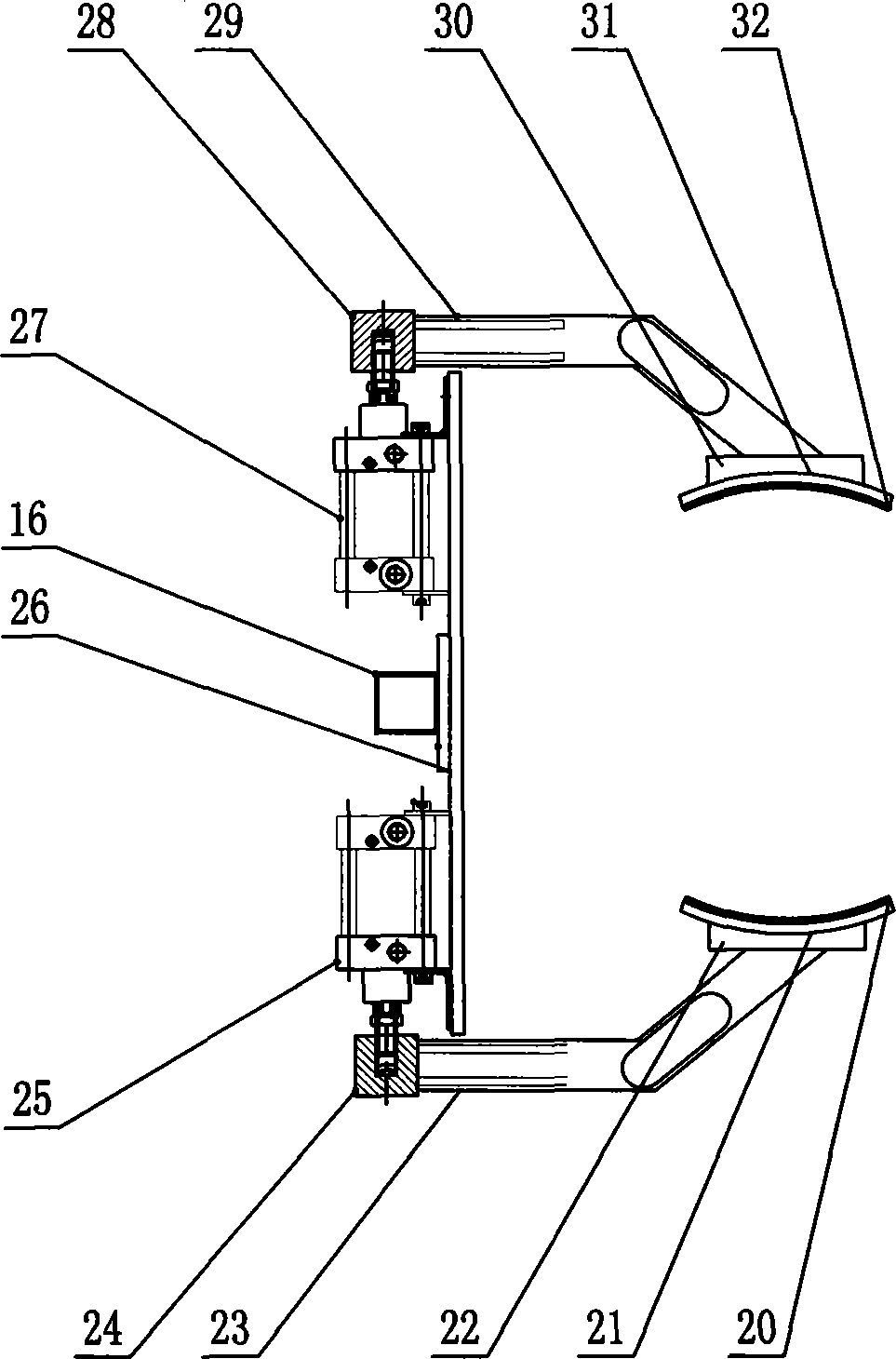

[0012] exist figure 1 , 2 Among them, the bottom plate 1 is fixed on the ground through expansion bolts, the middle part of the bottom plate 1 is provided with a column 2, and the top of the column 2 is provided with a main rotating seat 4, which can rotate 360°. The main rotating seat 4 is connected to the large side plate 7 through the main rotating shaft 5 connection, the large side plate 7 is provided with an air pressure control valve, the air pressure control valve is connected with the telescopic cylinder 3, the left lower end of the large side plate 7 is provided with a telescopic cylinder 3, and the guide rod is connected with the guide sleeve at the lower end of the small side plate 6, The big side plate 7 is provided with the small side plate 6, and the left side of the big side plate 7 is provided with a long strip waist-shaped hole sliding shaft groove, and two sliding shafts are arranged in the shaft groove, one is up and the other is divided, and the two sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com