Dual-station tank type de-ironing device

A two-station, trough-type technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low iron removal efficiency, low automation degree and work efficiency, and high manual labor intensity, so as to improve the removal efficiency. Iron efficiency, reduce labor intensity, improve the effect of iron removal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

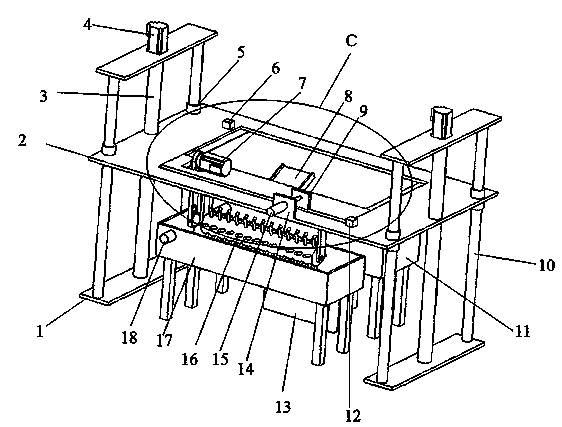

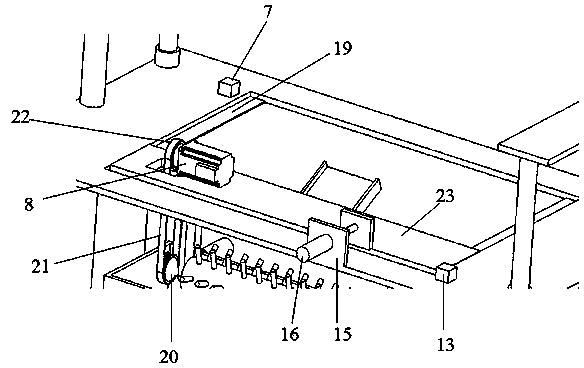

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

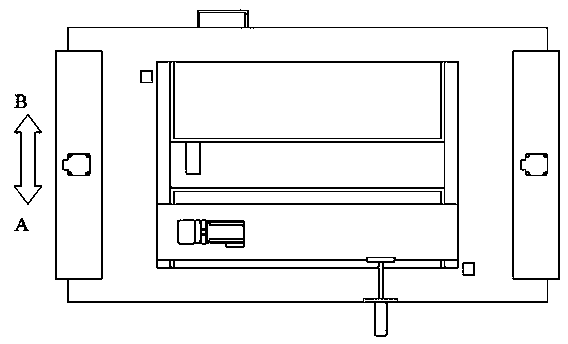

[0019] control figure 1 with figure 2 , before the device works, the up and down moving motor 4 installed on the main support 1 drives the up and down moving plate 2 to move upward along the guide column 10, the moving cylinder 15 pushes the horizontal moving plate 23 to move to the iron removal station, and the left travel switch 6 ensures its Accurate stop, the iron removal motor 7 is at a standstill, and at the same time, the iron removal mud flows from the iron removal tank inlet 8 into the iron removal tank 11, and the clean water flows into the cleaning tank 17 from the cleaning tank inlet 18, so far the preparation before iron removal is completed Work.

[0020] Then the deironing motor 7 starts, the small pulley 22 drives the large pulley 20 to rotate through the belt 21, the large pulley 20 drives the magnetic post 16 to rotate at a high speed, the up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com