Integrated motor protector

A comprehensive protection device, motor technology, applied in the direction of emergency protection circuit devices, electrical components, etc., can solve problems such as sudden power failure, motor coil current increase, motor coil burnout, etc., to reduce operating costs, improve work efficiency, and facilitate remote control The effect of centralized monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

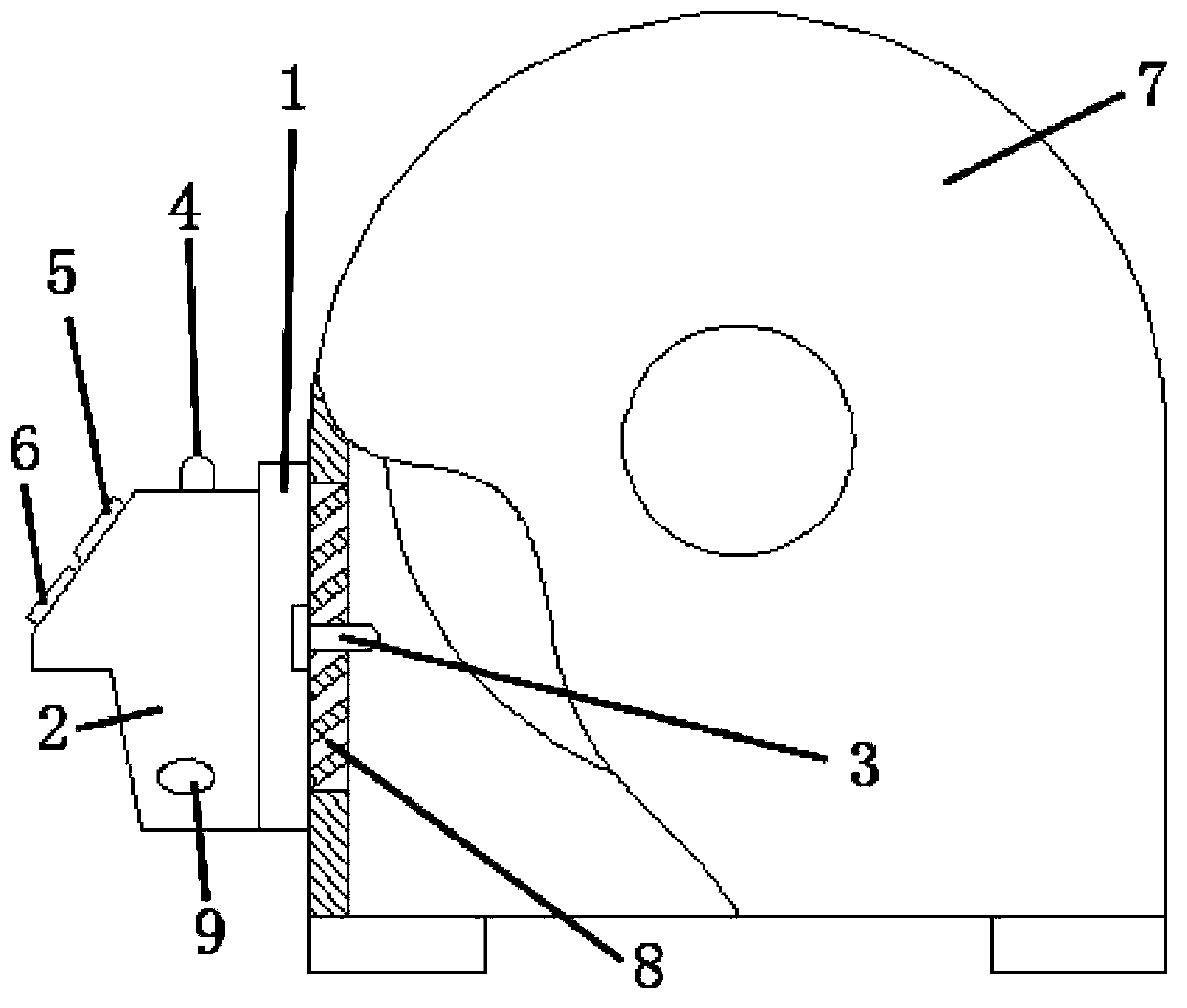

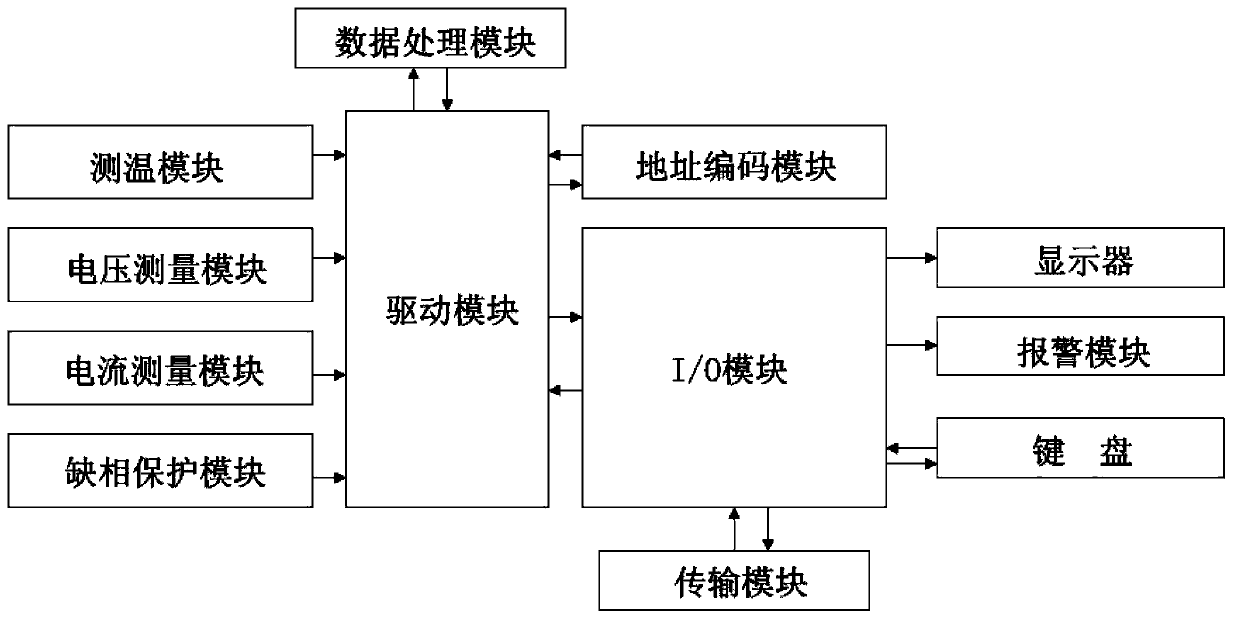

[0013] Such as figure 1 and 2 As shown, a motor comprehensive protection device, the comprehensive protection device consists of a base 1, a housing 2, a temperature measurement module 3, a voltage measurement module, a current measurement module, a phase loss protection module, an address coding module, a drive module, I / O module, alarm module 4, display 5, keyboard 6, transmission module and data processing module, wherein the housing 2 is located on the upper surface of the base 1, and the lower surface of the base 1 is connected to the heat dissipation port 8 of the motor 7, the described The voltage measurement module, current measurement module, phase loss protection module, address coding module, drive module, I / O module, transmission module and data processing module are all placed inside the housing 2, and the temperature measurement module 3 is placed on the base 1 on the lower surface and the detection probe is placed inside the motor 7, the alarm module 4, the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com