Low-cost consumable molten iron desulphurization mixer and preparation method thereof

A hot metal desulfurization and stirrer technology, which is applied in the field of low-cost consumption type hot metal desulfurization stirrer and its preparation, can solve the problems affecting the reduction of the cost of hot metal desulfurization, the high price of the stirrer, and the occupation of production time. Crack initiation, enhanced integrity and damage resistance, and reduced metal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

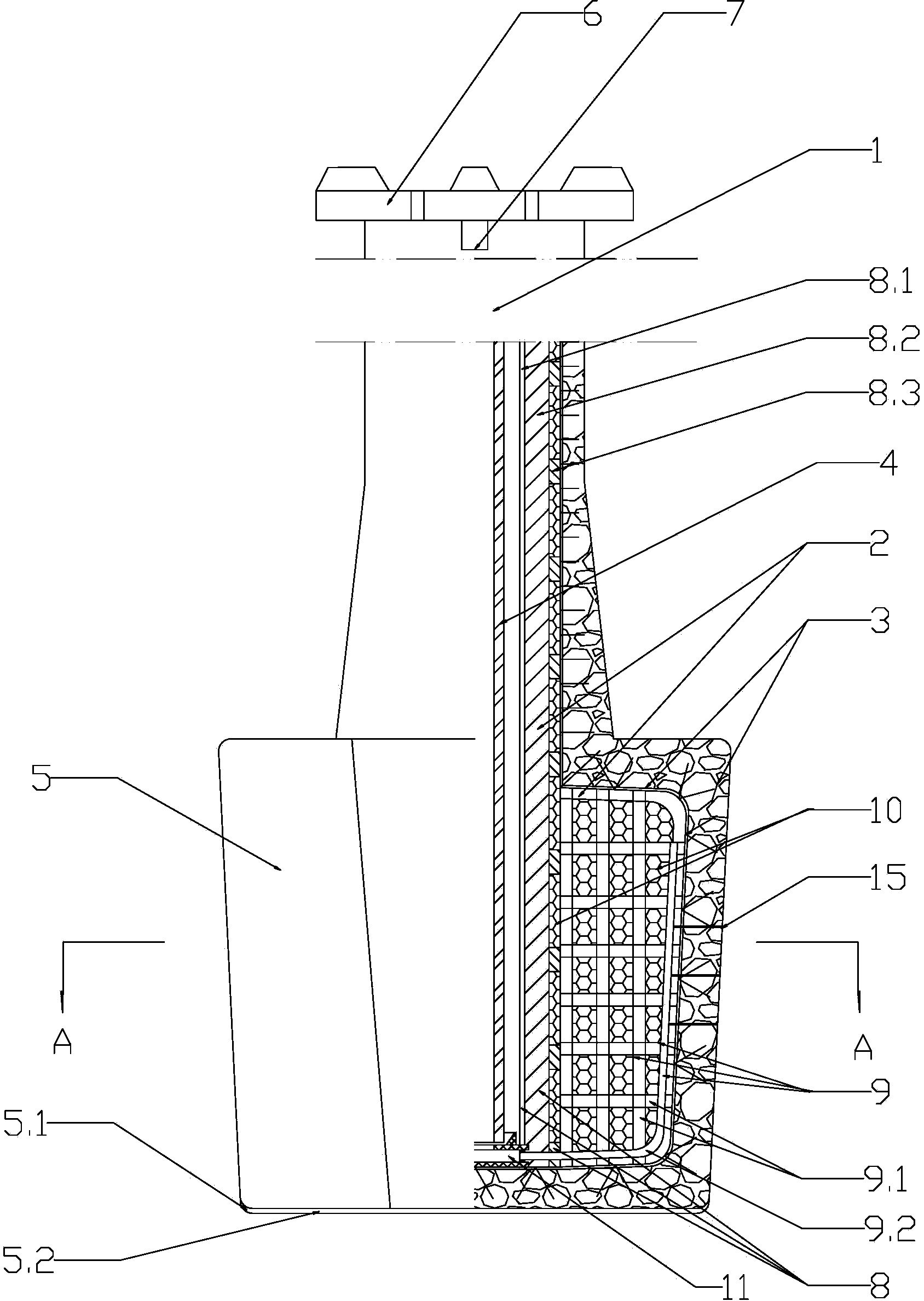

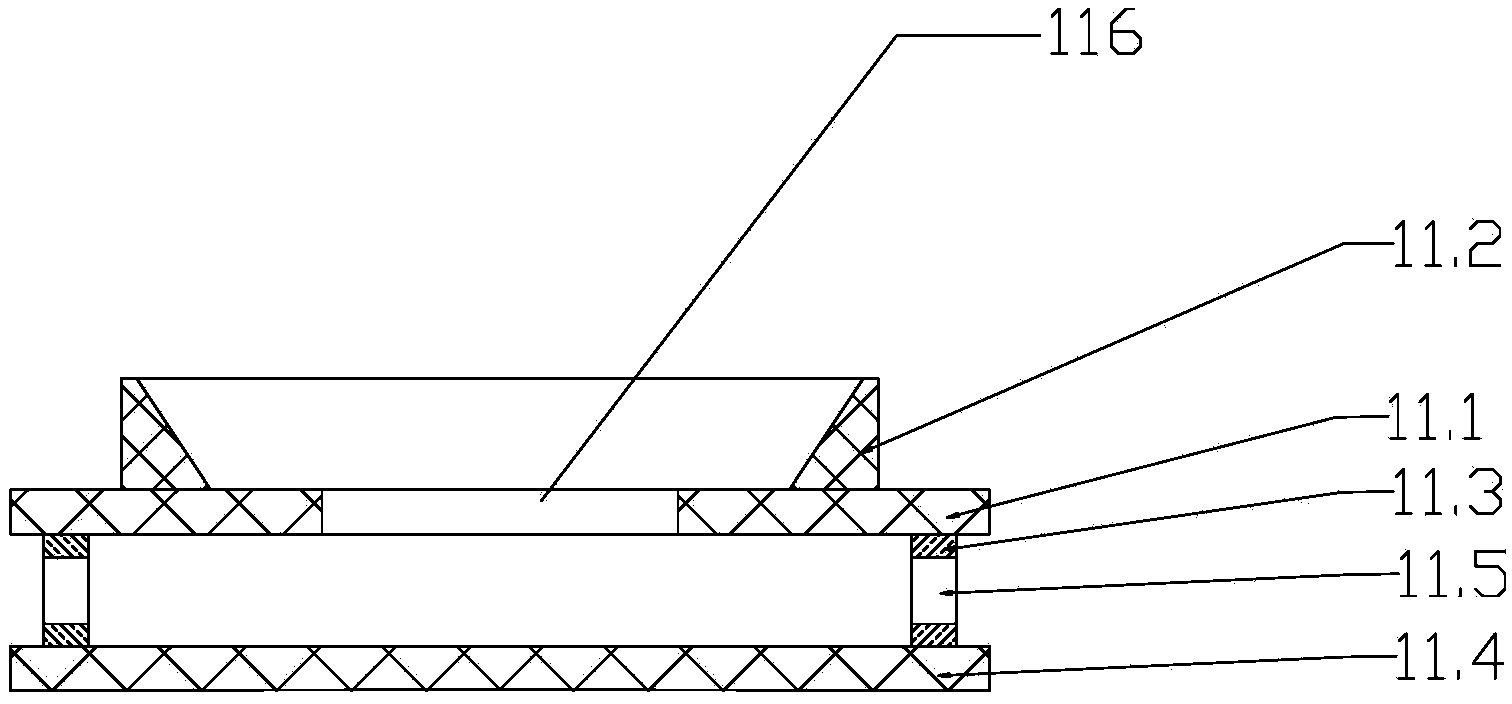

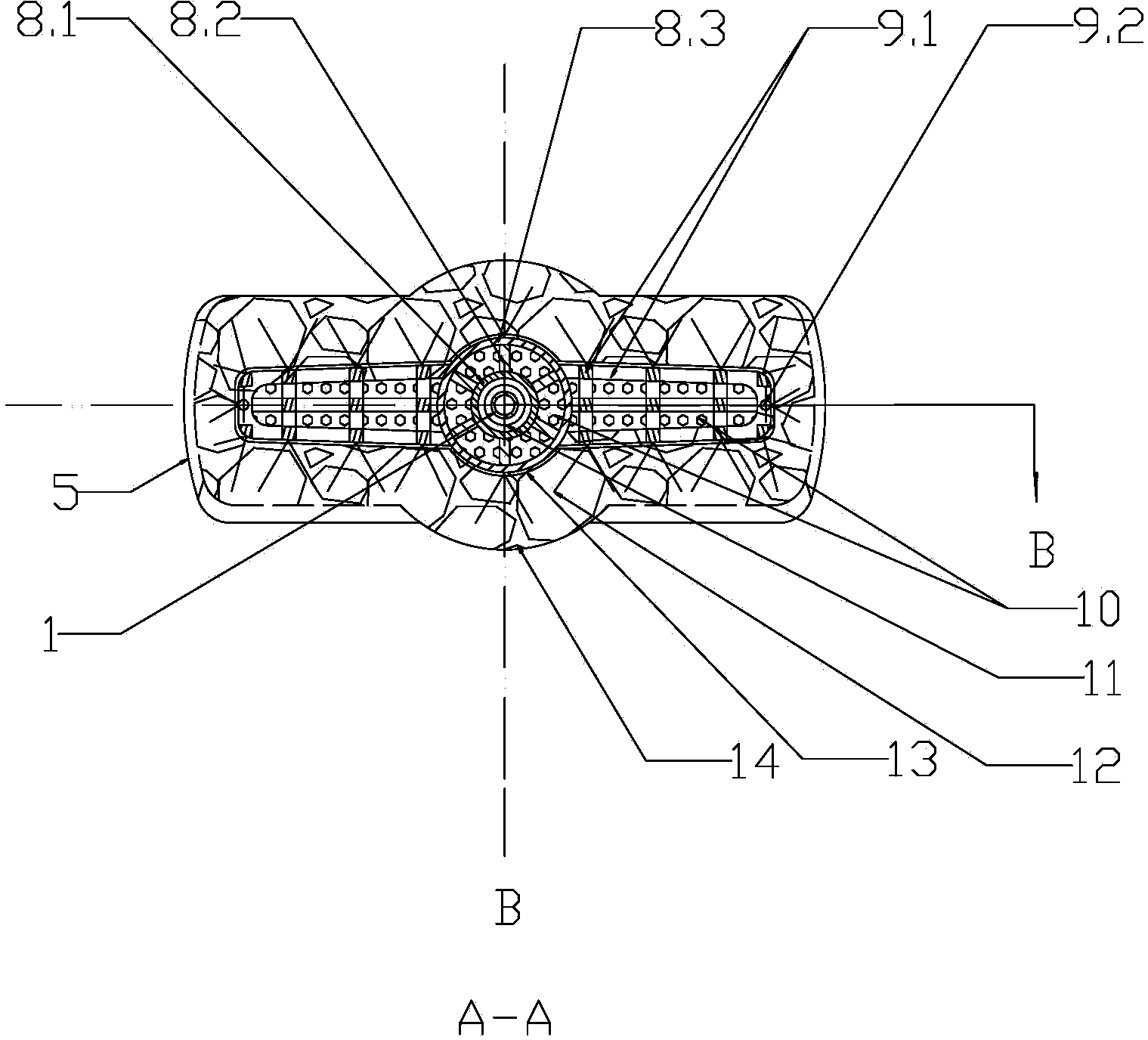

[0049] like Figure 1~4 As shown, a low-cost consumption type molten iron desulfurization agitator, the agitator includes a stirring shaft 1, a connecting flange 6 arranged above the stirring shaft 1, and the stirring shaft 1 is built-in gas cooling pipe 4 from the inside to the outside With the external composite stirring shaft core 2, a reinforcing rib plate 7 is arranged on the center line of the inner surface of the lower end of the connecting flange 6, and the top of the stirring shaft skeleton 8 is welded and connected with the connecting flange 6 and the reinforcing rib plate 7, and is connected by the reinforcing rib plate 7 Strengthen the connection between the stirring shaft skeleton 8 and the connecting flange 6 .

[0050] The lower end of the stirring shaft 1 is provided with two stirring blades 5, the outermost layers of the stirring shaft 1 and the stirring blades 5 are coated with a refractory working lining 3, and the surface edges of the refractory working lin...

Embodiment 2

[0073] like figure 1 , 2 As shown in and 5: the structure of this embodiment is basically the same as that of embodiment 1, the difference is that the number of stirring blades 5 is 3.

Embodiment 3

[0075] like figure 1 , 2 As shown in and 6: the structure of this embodiment is basically the same as that of embodiment 1, the difference is that the number of stirring blades 5 is four.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com