Railway passenger train body and railway vehicle

A technology for railway passenger cars and car bodies, applied in the direction of railway roofs and other directions, can solve problems such as inconvenience, low efficiency, and inconvenient operation, and achieve the effects of convenient maintenance, improved assembly efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

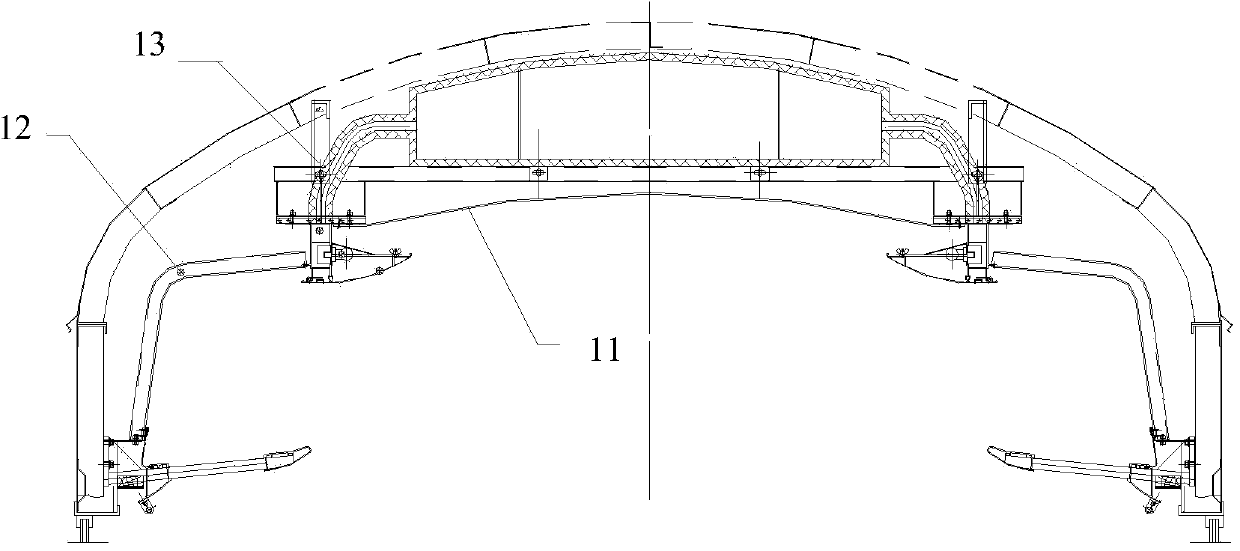

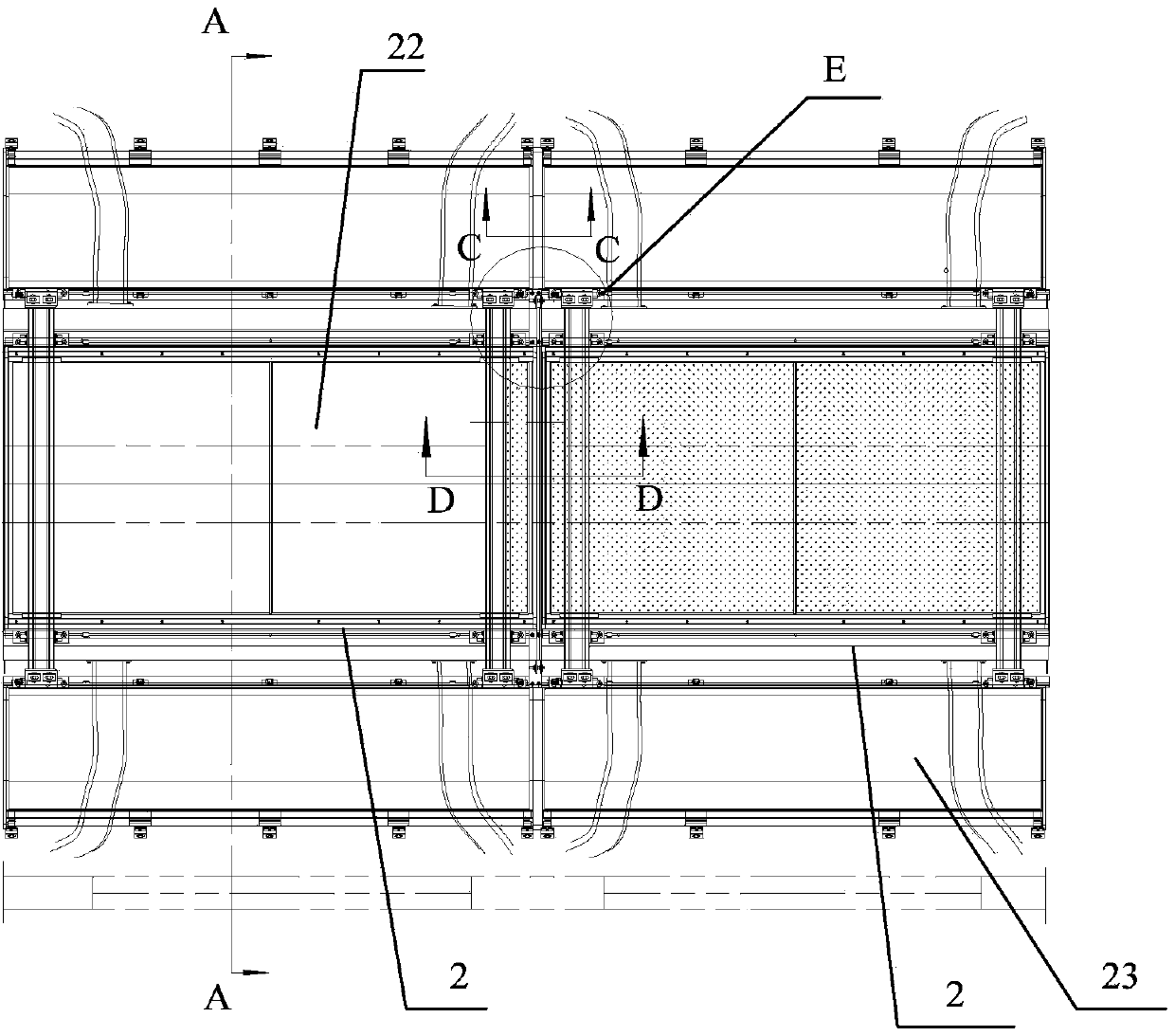

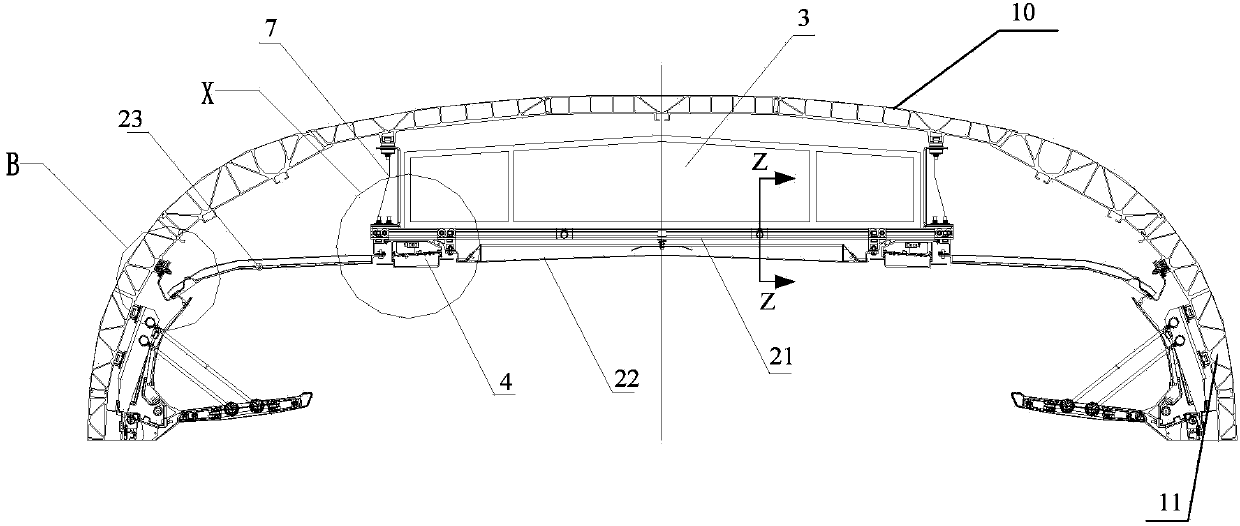

[0017] figure 2 It is a top view of the inner top plate in the railway passenger car body of the present invention; image 3 for figure 2 A-A sectional view; Figure 4 for figure 2 Middle D-D direction view; Figure 5 for figure 2 Middle C-C direction view; please refer to Figure 2-5 , the present embodiment provides a railway passenger car body, including a car body steel structure. At least two inner roof assemblies 2 arranged longitudinally; the inner roof assembly 2 includes: a skeleton 21, a middle roof 22, and side roofs 23 located on both sides of the middle roof 22; the skeleton 2 is fixedly connected to the inner surface of the roof 10 of the vehicle body; the skeleton It includes at least two longitudinally extending longitudinal beams 211 and at least two crossbeams 212 fixedly connected between the two longitudinal beams 211, the middle top plate 22 is covered under the frame 21, and the two sides are respectively fixedly connected to the two longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com