Clip type traveling distributor

A mobile distributor and clip-type technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor conveying effect, inconvenient use and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

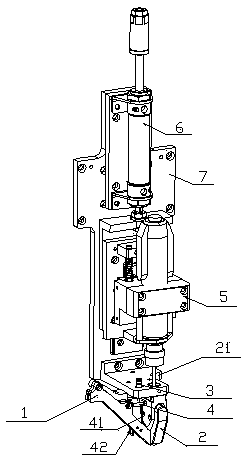

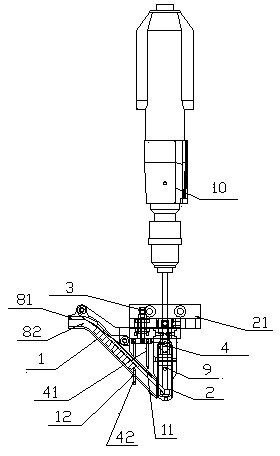

[0015] In this example, refer to figure 1 and figure 2 As shown, a clip-type mobile distributor of the present invention includes a storage guide rail 1, a lock mouth 2 connected to the lower end of the storage guide rail 1, and a lock mouth connection plate 21 arranged on the lock mouth 2, And the limit power mechanism 3 that is arranged on the side of the lock mouth 2 and is installed and connected with the lock mouth connection plate 21, and the limit connection plate 4 connected with the limit power mechanism 3, and the upper limit that is arranged on the limit connection plate 4 below Position rod 41 and lower limit rod 42; The top of described limit connecting plate 4 is provided with buffer mechanism 5; The above described buffer mechanism 5 is provided with propulsion power mechanism 6; The back of described propulsion power mechanism 6 is provided with Z-axis connection Plate 7; the storage guide rail 1 is obliquely connected to the lock nozzle 2, and the storage gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com