Method and device for quickly accumulating and removing scale in gathering and transportation pipelines

A technology for gathering and transporting pipelines, scale accumulation and descaling, which is applied in cleaning methods and utensils, chemical instruments and methods, and cleaning hollow objects, etc. To achieve the effect of simple on-site management, eliminating potential safety hazards and ensuring normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

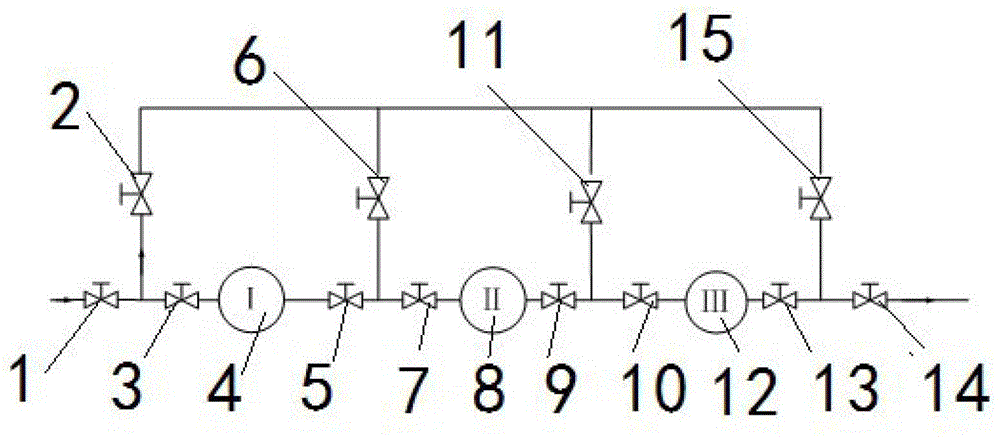

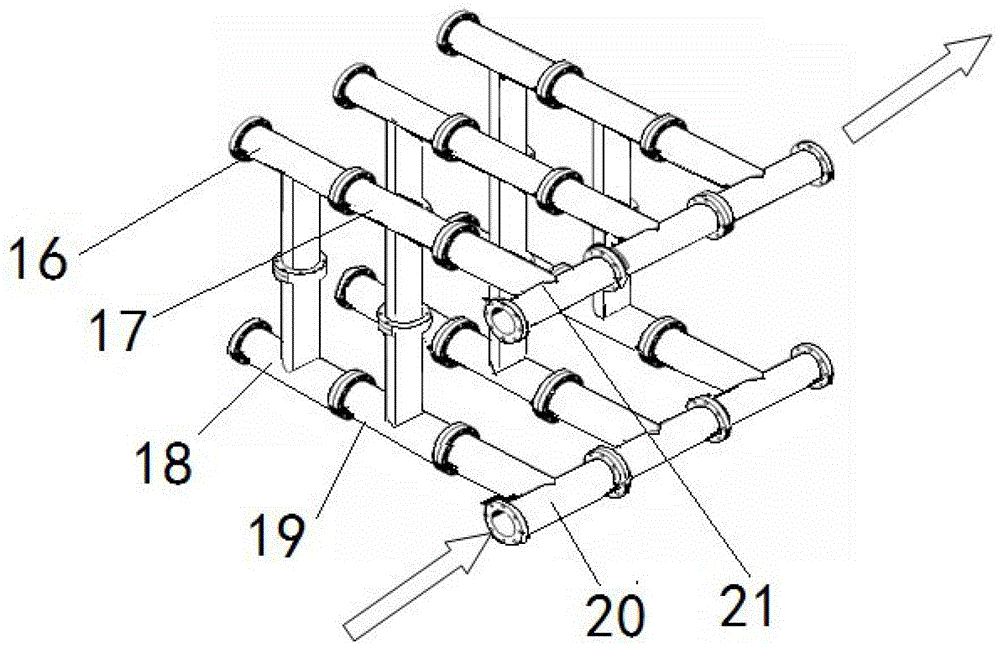

[0026] Embodiment 1: as figure 1 , figure 2 as shown,

[0027] A rapid accumulation and descaling device for gathering and transportation pipelines. Six three-way cylinders are connected by stainless steel flange connection pieces to form a set of descaling units. The structure of one set of descaling units is the right end of the first three-way cylinder 16 Connect the left end of the second three-way cylinder 17, the lower end of the first three-way cylinder 16 connects the upper end of the third three-way cylinder 18, and the right end of the second three-way cylinder 17 connects the upper end of the sixth three-way cylinder 21 , the lower end of the second three-way cylinder 17 is connected to the upper end of the fourth three-way cylinder 19, the left end of the fourth three-way cylinder 19 is connected to the right end of the third three-way cylinder 18, and the right end of the fourth three-way cylinder 19 Connect the upper end of the fifth three-way cylinder 20;

...

Embodiment 2

[0032] Embodiment 2: as figure 1 , figure 2 as shown,

[0033]A rapid accumulation and descaling device for gathering and transportation pipelines. The component unit is a standard three-way cylinder. The inner diameter of the cylinder is 2 to 3 times the diameter of the gathering and transportation pipeline. The flow rate of the liquid entering the cylinder will be reduced to 1 / 2 of the original 4 to 1 / 8, ensuring sufficient time and space for scaling. Six three-way cylinders are connected by stainless steel flanges to form a group of descaling units. The upper and lower horizontal cylinders of each group of descaling units are equipped with heating rod working cylinders. The outer diameter of the heating rod working cylinders is a three-way 1 / 3~1 / 2 of the inner diameter of the cylinder, the heating rod working cylinder is connected with the end flange of the three-way cylinder, which ensures the sealing and is easy to disassemble. The electric heating rod is inserted int...

Embodiment 3

[0044] Embodiment 3: as figure 1 , figure 2 As shown, the average daily fluid production of a well in Xinjiang Chepaizi Oilfield is 25t, the average water content is 25%, the salinity of the produced water is 59463.77mg / l, and the content of calcium ions is also high; at the same time, due to the production The content of hydrogen sulfide in the liquid reached 4067.76mg / m 3 , so add sulfur remover. The single well gathering and transportation pipeline of this well is a steel pipe of about 60mm. If it is completely blocked, it is necessary to hot wash the gathering and transportation pipeline of a single well every 7 days to remove the blockage or replace a new pipeline, and due to the poor effect of hot washing and descaling, it is necessary to regularly replace the new single well gathering and transportation pipeline every 40 days.

[0045] In response to the above situation, the rapid accumulation and scale removal process of the gathering and transportation pipeline wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com