Preparation method of non-symmetrical inner wall separation membrane

A separation membrane and asymmetric technology, which is applied in the field of preparation of asymmetric inner wall separation membrane, can solve the problems such as the inability to industrially produce the inner membrane of asymmetric porous filter membrane tubes, and achieve the effect of rapid preparation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

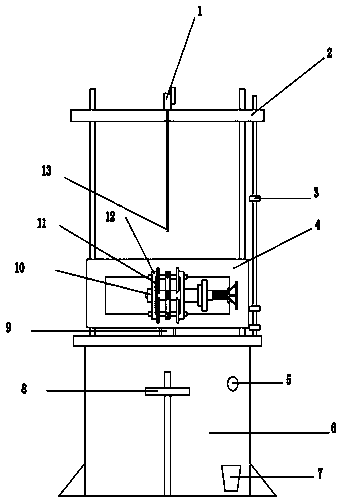

[0035] The selected equipment structure of the present invention is as follows:

[0036] Such as figure 1 As shown, it includes the box body (6) and the workbench (4). The workbench (4) is located on the box body (6) and connected by the cylinder (9). The workbench (4) moves up and down under the drive of the cylinder (9). Reciprocating movement; the side plate is installed next to the workbench (4) parallel to the workbench, the metal sensor (3) is installed on the side plate, the supporting plate (8) is installed on the base of the box; the spray gun (13) is installed on On the support of the workbench, it is perpendicular to the workbench and coaxial with the support plate; the bottom of the asymmetric inner wall separation membrane tube is installed on the support plate (8), and the clamping assembly is located on the workbench (4). The separation membrane tube on the inner wall is fixed, and moves up and down with the worktable under the action of the cylinder, and the...

Embodiment 2

[0047] 1) Weigh a certain quality of stainless steel 304 powder, mix it evenly with the dispersant, and the solid content of the slurry is 25%;

[0048] 2) Add a small amount of defoamer to the powder slurry in step (1) to remove the gas in the powder slurry;

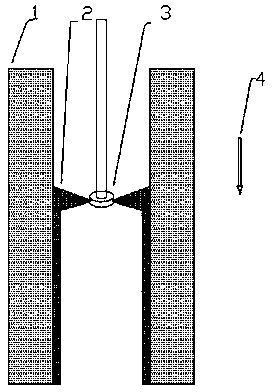

[0049] 3) Put the slurry configured in step (2) into the mixing tank, so that the slurry is in a stirring state. When working, the uniformly mixed slurry is directly supplied to the top of the molding equipment through the action of high-pressure gas—the spray gun (1 );

[0050] 4) In this example, according to the following performance parameters: the length of the prepared inner wall membrane tube is 750mm, the inner diameter of the membrane tube is 60mm, and the thickness of the prepared membrane layer is 25um, adjust the equipment figure 1 According to the working parameters of (1), (8), (9), (10), (11), (12), and (13), adjust the metal sensor (3) on the workbench according to the length of the porous tube matrix. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com