Multi-tubular reactor and multi-tubular reactor design and fabrication method

A manufacturing method and reactor technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problem of large difference of heat medium, increase of flow resistance of heat medium, and change of heat conduction state of reaction tube And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

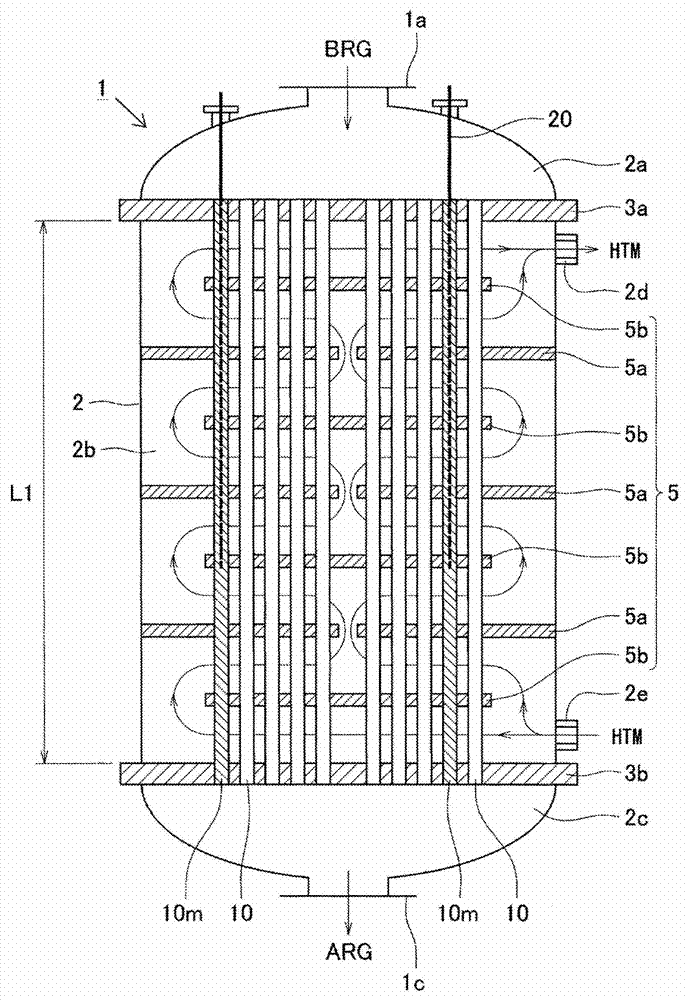

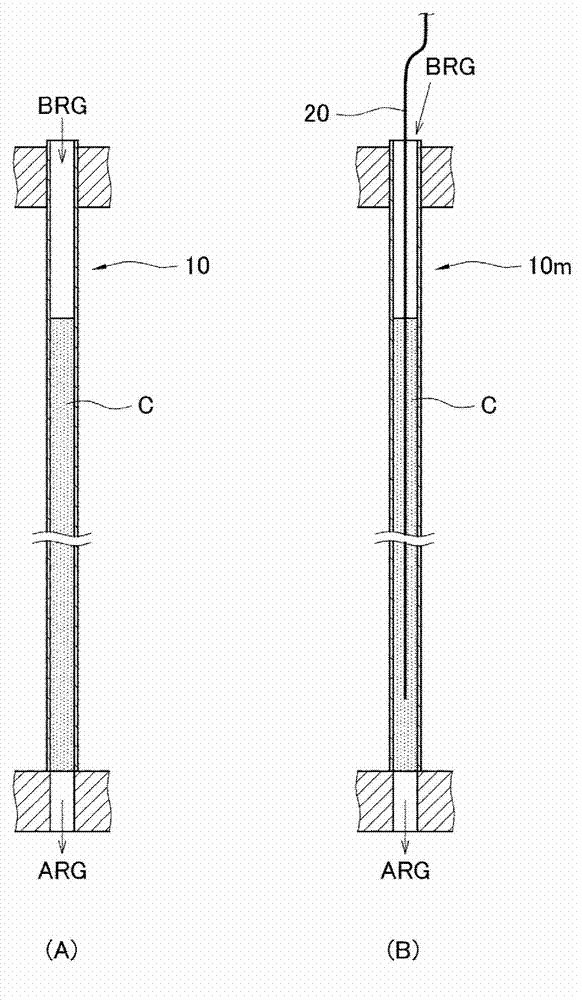

[0194] In an embodiment of the present invention, in a multi-tubular reactor in which a plurality of reaction tubes are arranged in the above-mentioned triangle, the flow state of the heat medium is confirmed by numerical simulation.

[0195] In this numerical simulation, for example, as figure 2 As shown, in the case where a disc-annular baffle plate 5, especially an annular baffle plate 5a, is provided in a cylindrical shell, in order to confirm the flow toward the radial direction that can be generated in the reactor, it is confirmed that The flow conditions of the heat medium at the section of the multi-tubular reactor are analyzed.

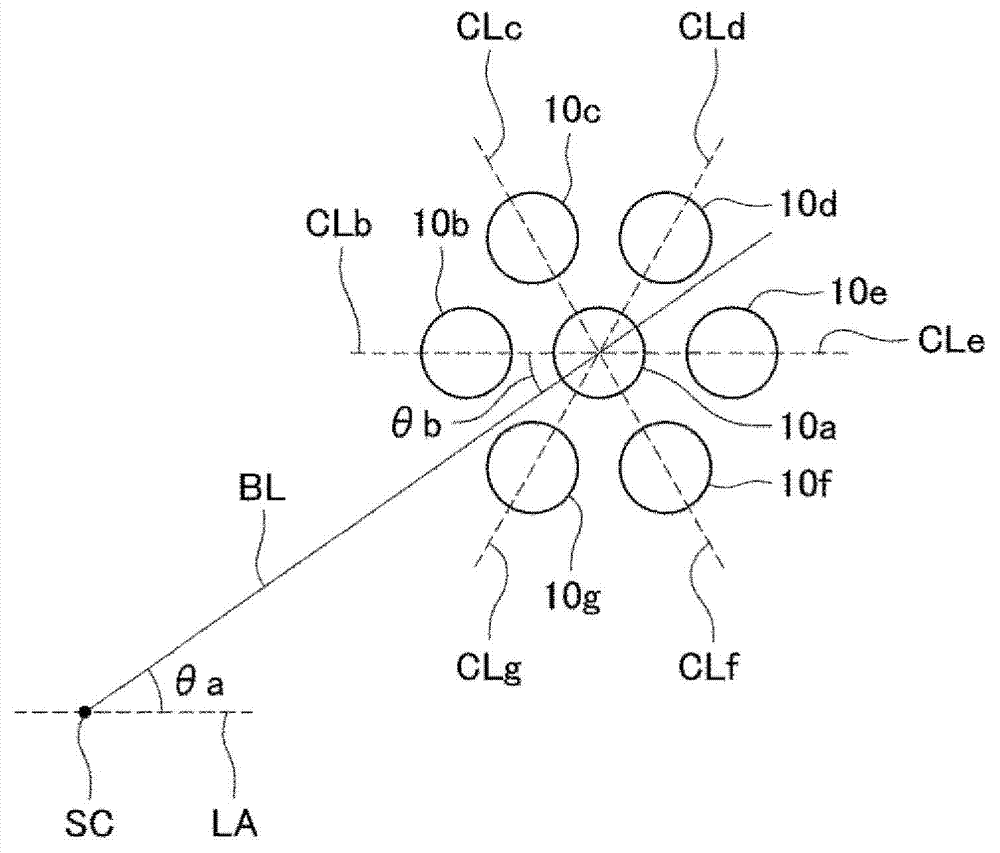

[0196] It should be noted that, in the case of arranging a plurality of reaction tubes in a triangular arrangement, since an axisymmetric flow can be formed with respect to the central axis of the cylindrical shell of the reactor, as Figure 4 As shown, in this numerical simulation, it is not carried out in the entire section of the multi-tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com