Touch switch and manufacturing method of switch spring plate

A tact switch, shrapnel technology, applied in electrical switches, manufacturing tools, electrical components, etc., can solve the problems of unstable contact, long stroke, short shrapnel life, etc., to achieve comfortable pressing feel, reduce pressing stroke, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

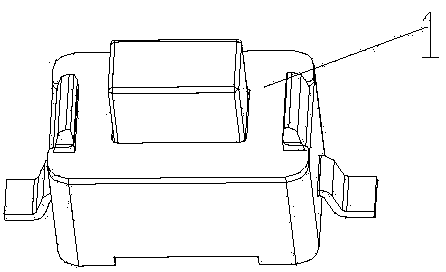

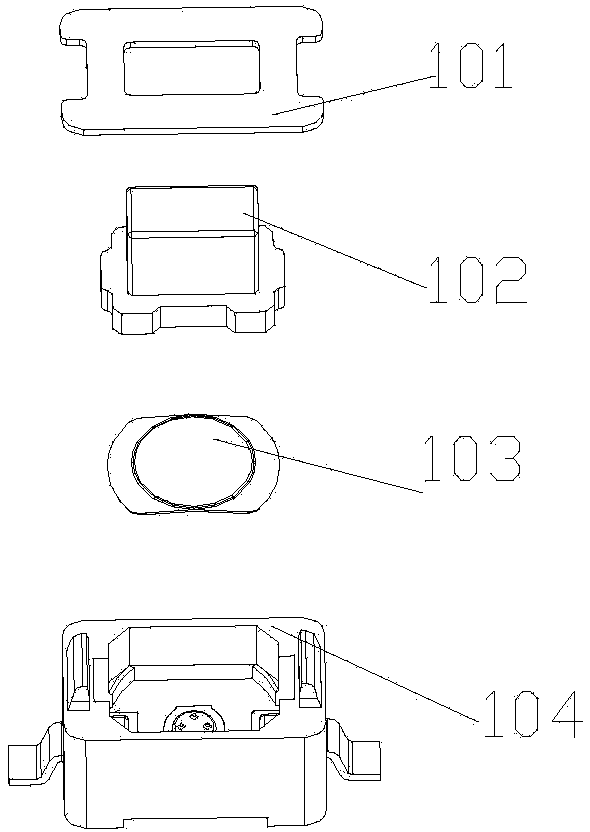

[0017] refer to figure 1 , figure 2 , image 3 , Figure 4 As shown: a tact switch 1 is designed, which is provided with a base 104, a conduction piece sequentially arranged in the base 104, a shrapnel 103, a button 102 and an upper cover 101 buckled with the base. The shrapnel 103 is approximately rectangular, Its middle part is a circular plane 105, and two opposite outer edges of the circular plane 105 protrude outwards and downwards a section of skirt 103 that makes the shrapnel arched and symmetrical; the outer edge of the skirt 103 is arc-shaped structure; it can also be formed by cutting the outer circle of diameter B; the symmetrical sides on both sides of the skirt 103 are tangent to the outer circle of the circular plane 105 to form two parallel straight sides, which can also be larger than the circular plane 105 diameter, formed as image 3 Skirt width A shown.

[0018] In the above tact switch, the circular plane 105 is integrally formed with the symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com