Displacement sensor follower mechanism for testing the thickness of the oil film on the auxiliary shoe

A displacement sensor, oil film thickness technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of data cable winding, complex sliding shoe movement state, and small sensor installation position, to achieve the effect of solving winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

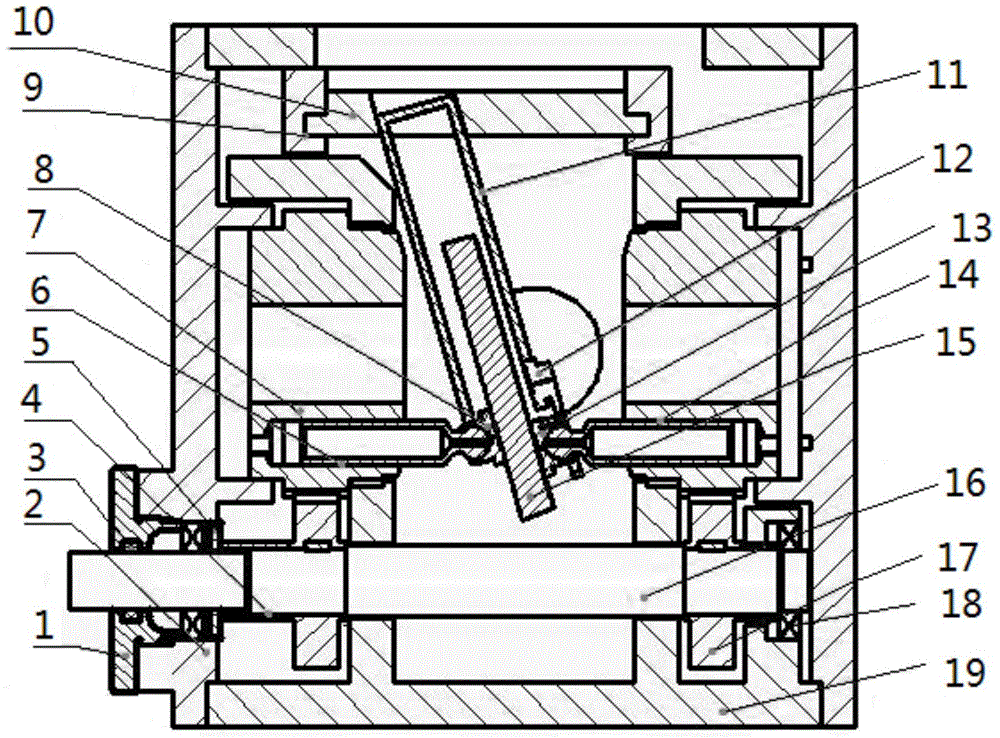

[0018] The present invention will be further described below in conjunction with accompanying drawing, with reference to accompanying drawing:

[0019] figure 1 Among them, 1 is the bearing end cover, 2 is the housing end cover, 3 is the felt ring, 4 is the sleeve, 5 is the oil seal, 6 is the auxiliary test plunger, 7 is the auxiliary test cylinder, 8 is the auxiliary test slide shoe 9 is The first sliding bracket, 10 is the second sliding bracket, 11 is the support frame, 12 is the sensor mounting plate, 13 is the test shoe, 14 is the test shoe, 15 is the swash plate, 16 is the transmission shaft, 17 is the pinion, The 18th, bearing, 19 housings.

[0020] The displacement sensor follower mechanism for testing the thickness of the auxiliary oil film of the slide shoe includes a housing 19 and a housing end cover 2. The main shaft is arranged in the housing 19 through a bearing. The main shaft is provided with a pinion 17 for input power and a pinion for output power. left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com