Continuous type aluminum alloy melting furnace

A technology of aluminum alloy and melting furnace, which is applied in the field of aluminum alloy smelting to achieve the effects of shortening heat conduction distance, reducing consumption, and reducing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be further described below in conjunction with the accompanying drawings.

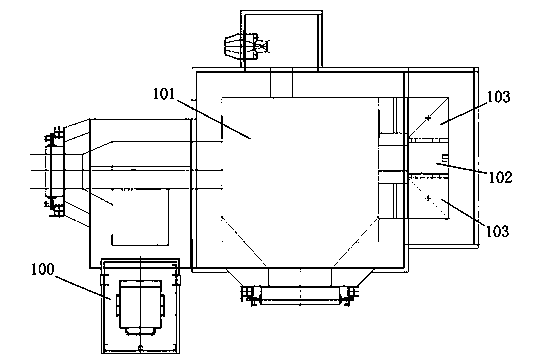

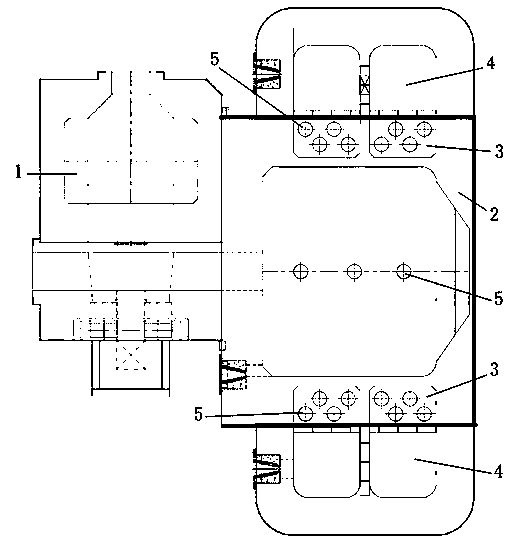

[0031] Such as figure 2 As shown, the aluminum alloy continuous melting furnace described in the present invention includes a melting furnace 1, a holding furnace 2, a degassing chamber 3 and a use chamber 4, the degassing chamber 3 communicates with the use chamber 4, and the use chamber 4 is located in the The outside of the holding furnace 3; the melting furnace 1 is used to melt the raw material into aluminum alloy liquid, and then the aluminum alloy liquid enters the holding furnace 2 for heat preservation, the degassing chamber 3 is used to degas the aluminum alloy liquid, and the aluminum alloy in the use chamber 4 Alloy liquid can be taken directly to casting production. (Whether the process and function description is correct)

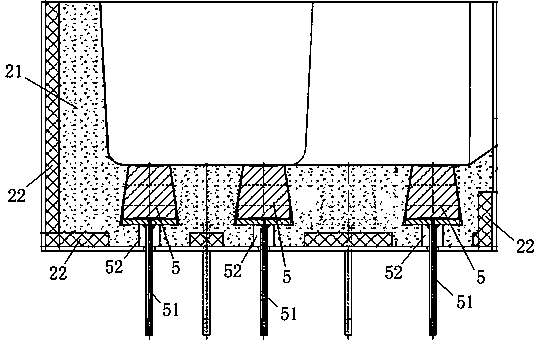

[0032] In order to reduce the heat dissipation area of the aluminum alloy liquid on the outside, and also shorten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com