Electric flocculation wastewater treatment electrode

A wastewater treatment and electro-flocculation technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low adsorbent capacity, high cost, difficult regeneration, etc., and achieve the treatment effect Good, responsive, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

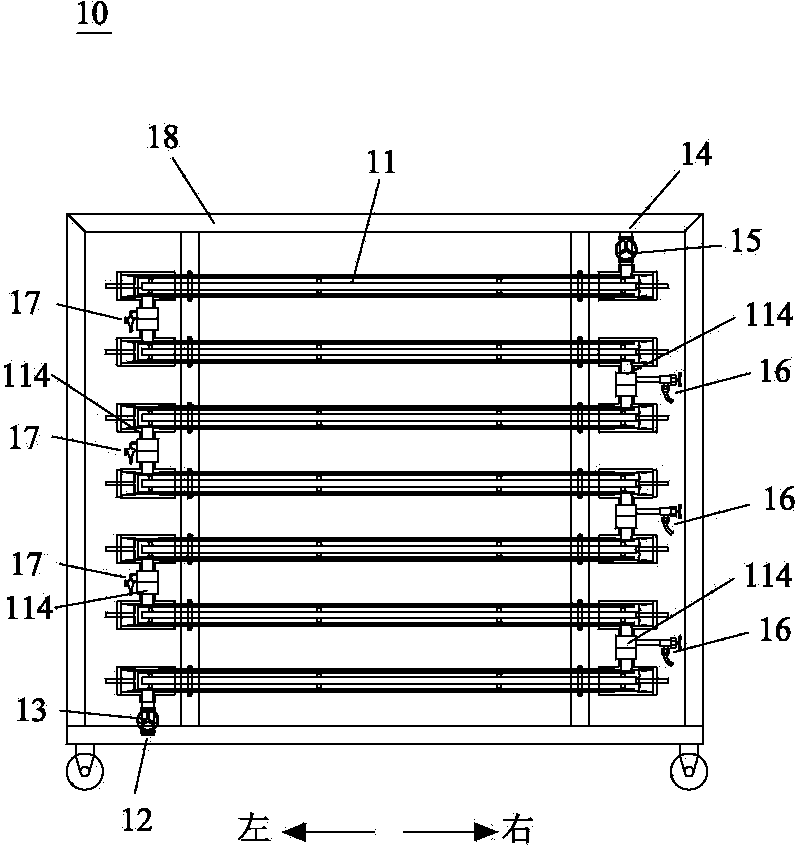

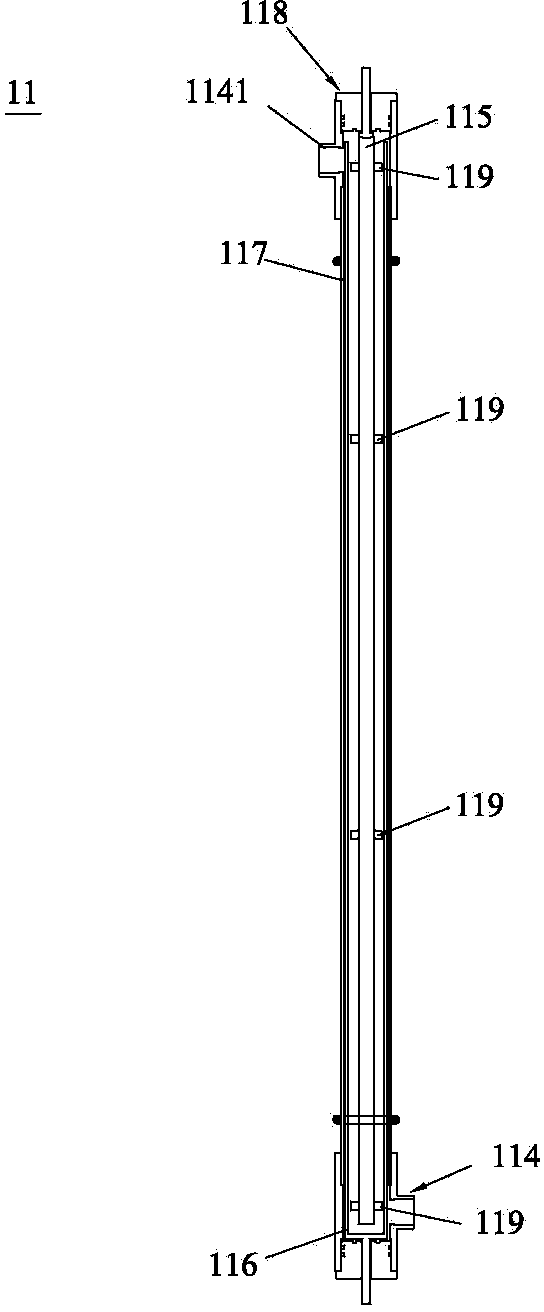

[0051] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the electrocoagulation wastewater treatment device 10 of the preferred embodiment of the present invention. The electrocoagulation wastewater treatment device 10 is composed of multiple sections of pipelines 11 circuitously connected in series. Water inlet 12 is arranged, and water inlet valve 13 is installed at this water inlet 12 places. A water outlet 14 is provided on the final pipeline 112, and a pressurizing valve 15 is installed at the water outlet 14. A detection valve 16 is installed at the joint 114 of any section of pipeline 113 in the middle and its upper section of pipeline, and a dosing valve 17 is installed at the joint 114 of its next section of pipeline.

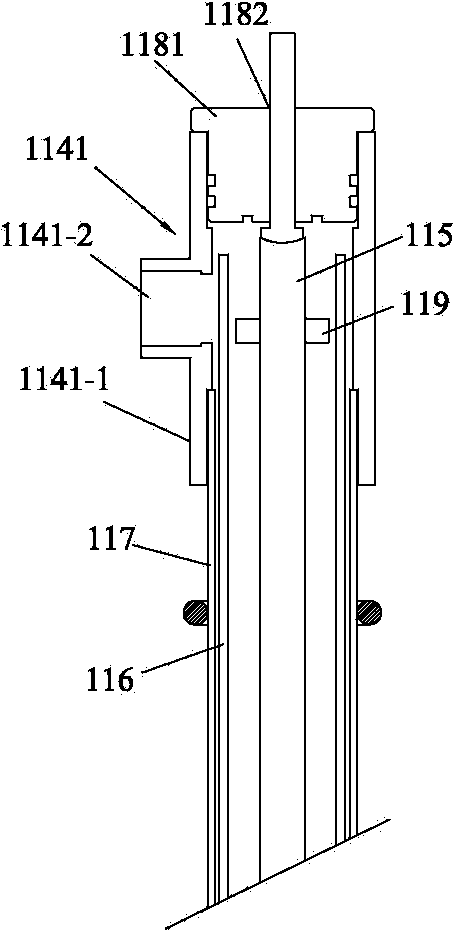

[0052] like Figure 2 to Figure 5 As shown, each section of tubing 11 includes an anode 115 and a cathode 116 for electrocatalysis. The cathode 116 is tubular, forming a lumen 1161 inside the cathode 116; the anode 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com