Heating device for blade of circle shear

A heating device and disc technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long time-consuming, easily damaged cutting blades, and affecting the effective working efficiency of the unit, so as to reduce labor load and improve work efficiency. Efficiency, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

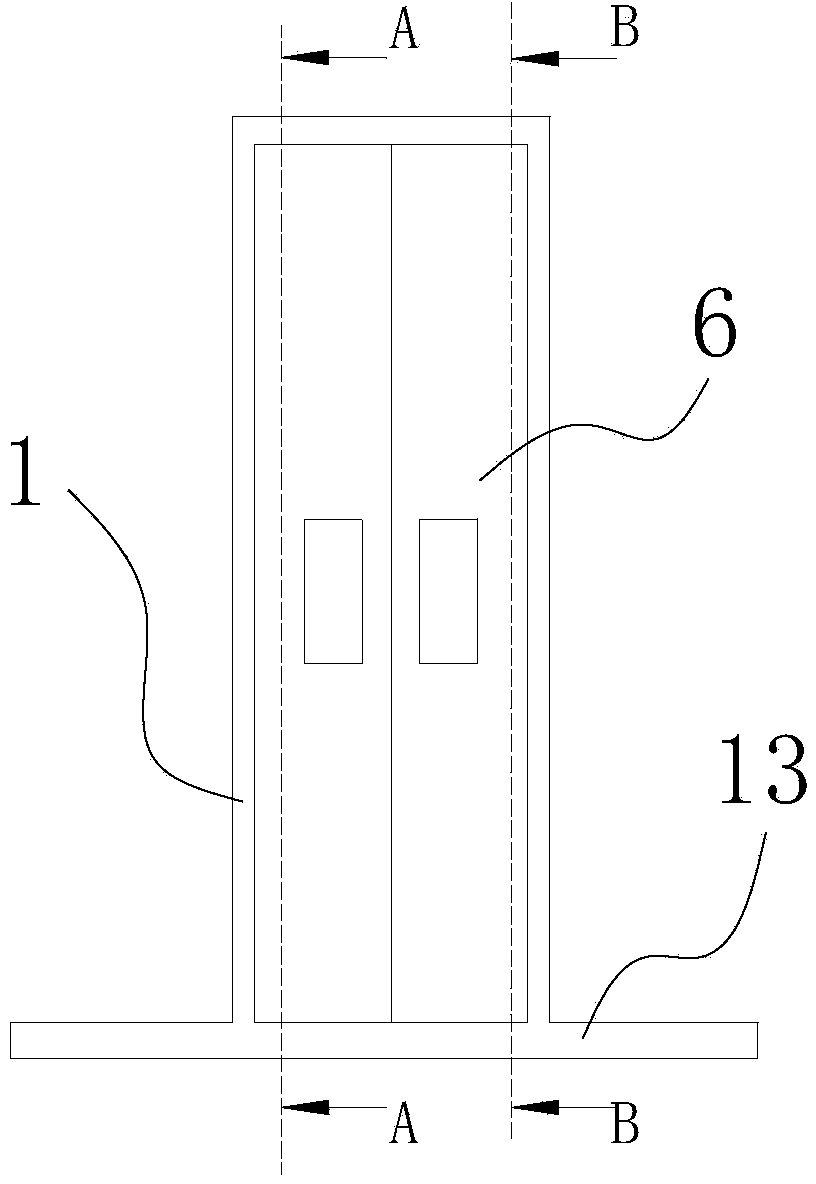

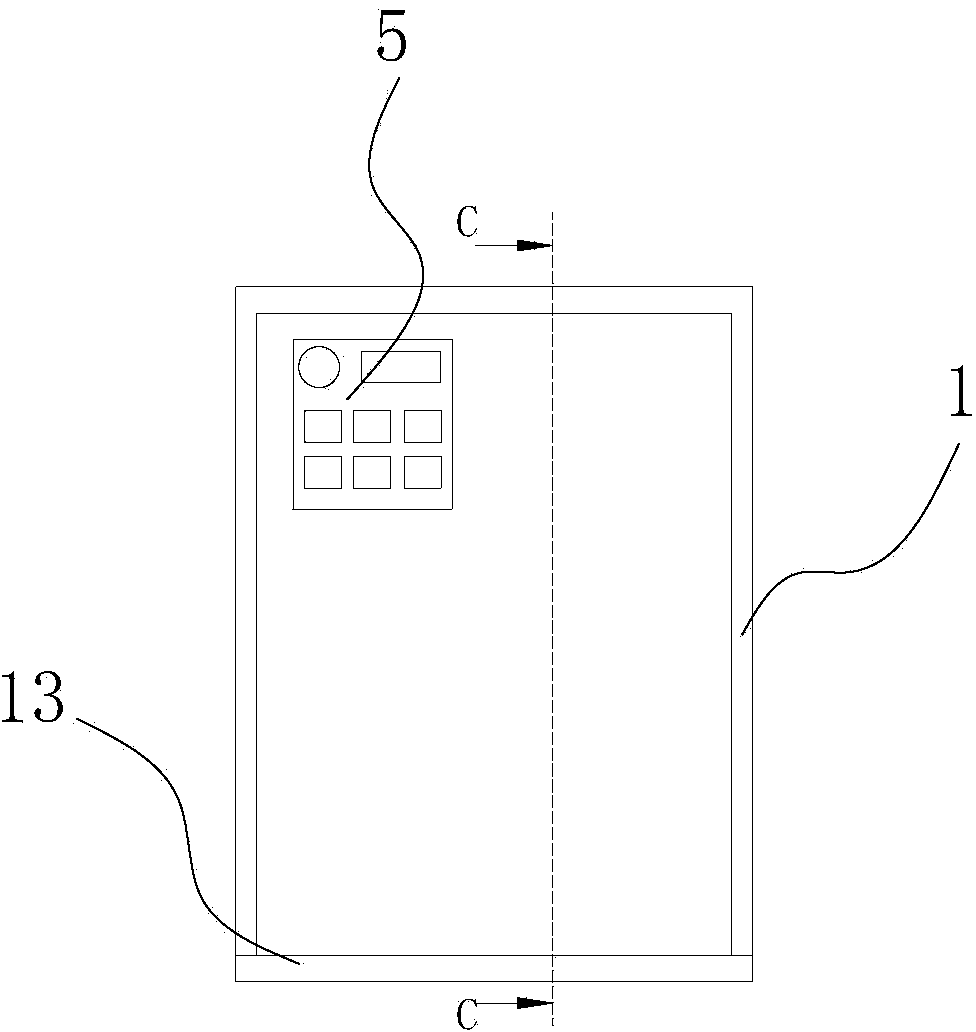

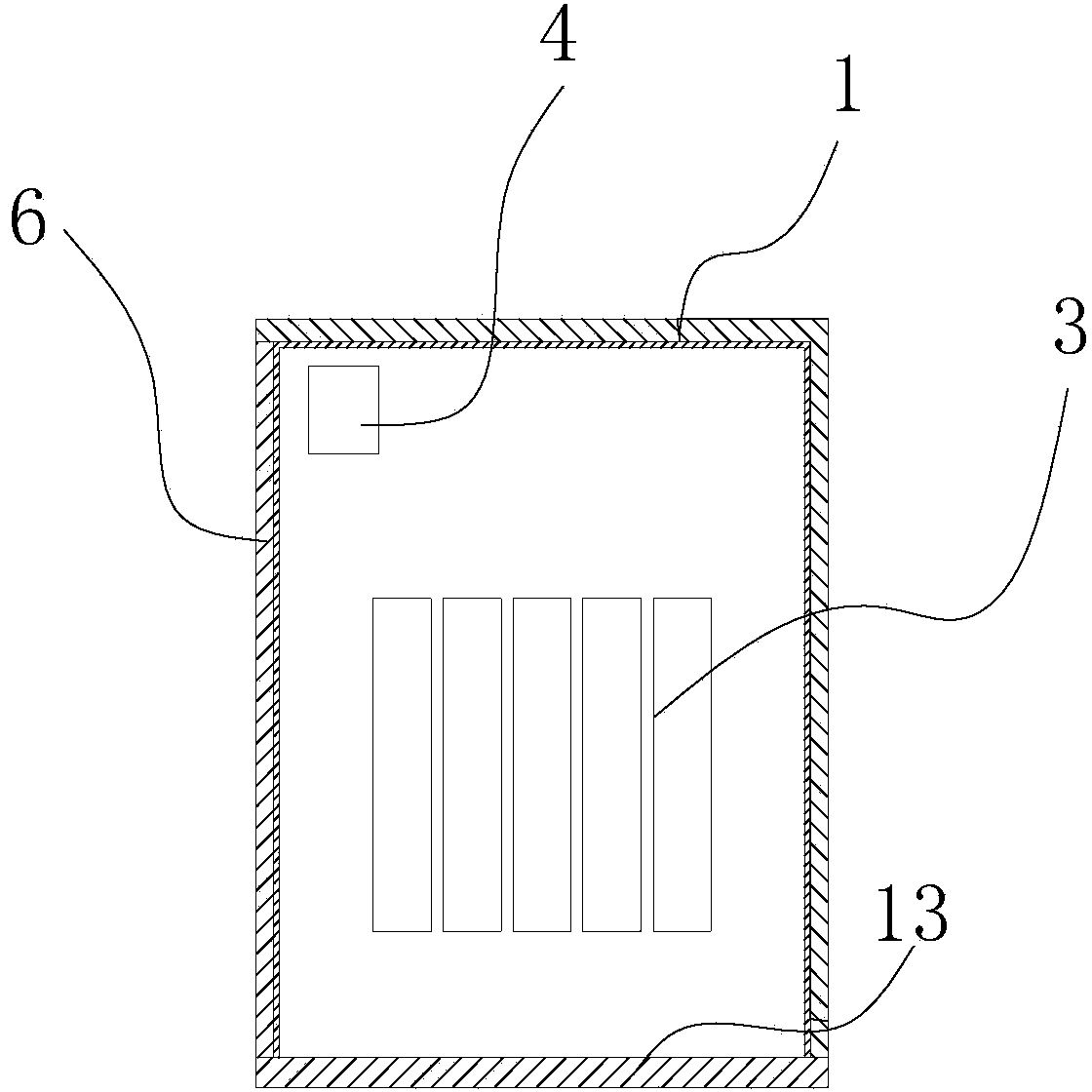

[0045] Such as Figure 1 to Figure 9 As shown, the heating device for disc scissors includes a heating box 1; the heating box 1 has an inner cavity; the bottom surface of the heating box 1 inner cavity is provided with a bracket 2; the inner wall of the heating box 1 inner cavity The heating box 1 is provided with a resistance heating sheet 3 or the inner wall of the inner cavity of the heating box 1 and the top surface of the inner cavity are provided with a resistance heating sheet 3; the heating box 1 is provided with a scissor inlet; the scissor inlet is provided with a closed The switch door 6 at the entrance of the scissor blade, the outer surface of the heating box 1 is provided with a power switch, and the resistance heating sheet 3 is electrically connected with the power switch.

[0046] A temperature sensor 4 is arranged in the inner cavity of the heating box 1 , and a temperature adjustment control device 5 is arranged on the outer surface of the heating box 1 ; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com