Roasting machine

A roaster machine and casing technology, which is applied in the field of food manufacturing machines, can solve problems such as easy burning, uneven heating of goods, and difficulty in moving, so as to avoid waste, mix goods evenly, and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

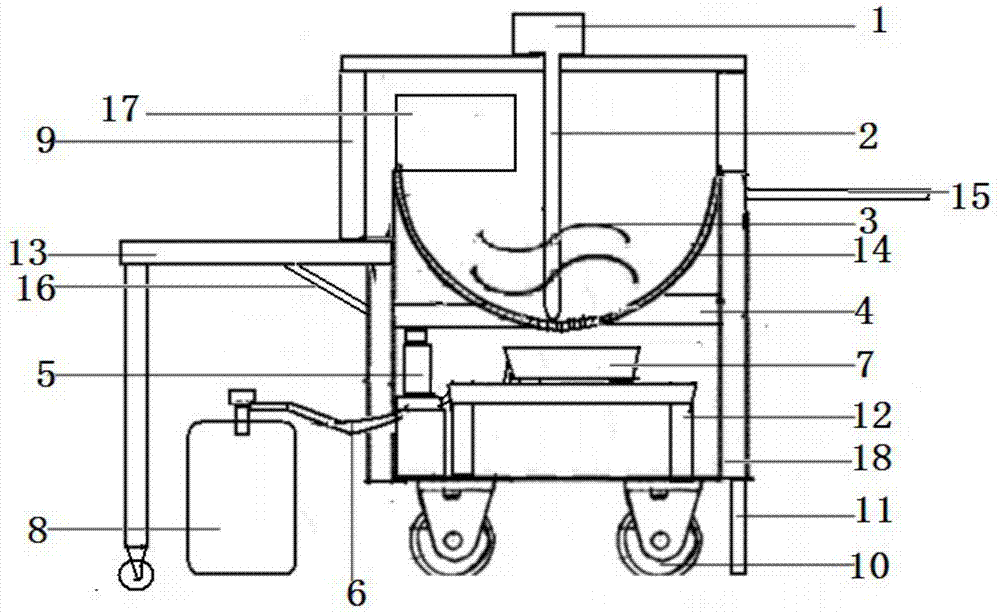

[0025] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments. A roaster machine of the present invention is composed of a structural casing 18, a workbench 13, a frying pan 14, a pot fixing frame 4, a stirring support frame 9, a heat source 7, a motor 1, a transmission shaft 2, a stirring plate 3, and a jacking device 5, Wherein the frying pan 14 is positioned on the pot fixing frame 4, the pot fixing frame 4 is a hollow ring structure, the bottom of the frying pan 14 is in contact with the heat source 7, one side of the pot fixing frame 4 is provided with a jacking device 5, and one side of the stirring support frame 9 Located on the casing 18, one side is fixed on the workbench 13, a motor 1 is provided on the crossbeam of the stirring support frame 9, the motor 1 is connected to the transmission shaft 2, and the transmission shaft 2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com