Double-row peanut seeder on rotary tillage stubble ploughing separated layer fertilization ridge

A peanut seeder and layered fertilization technology, which is applied to agricultural machinery and tools, shovels, plows, etc., can solve the problems of not being able to seal ridges, and achieve the effects of reducing wind erosion, improving economic benefits, and reducing soil water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

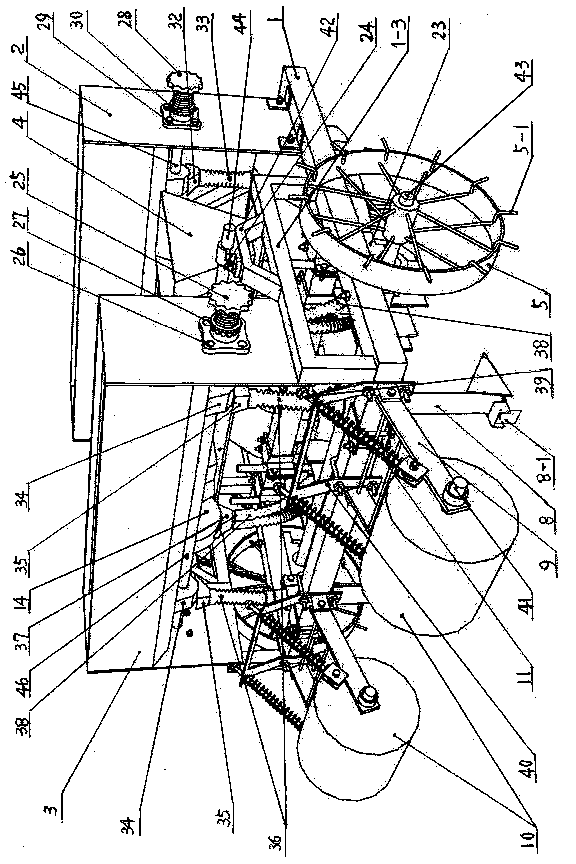

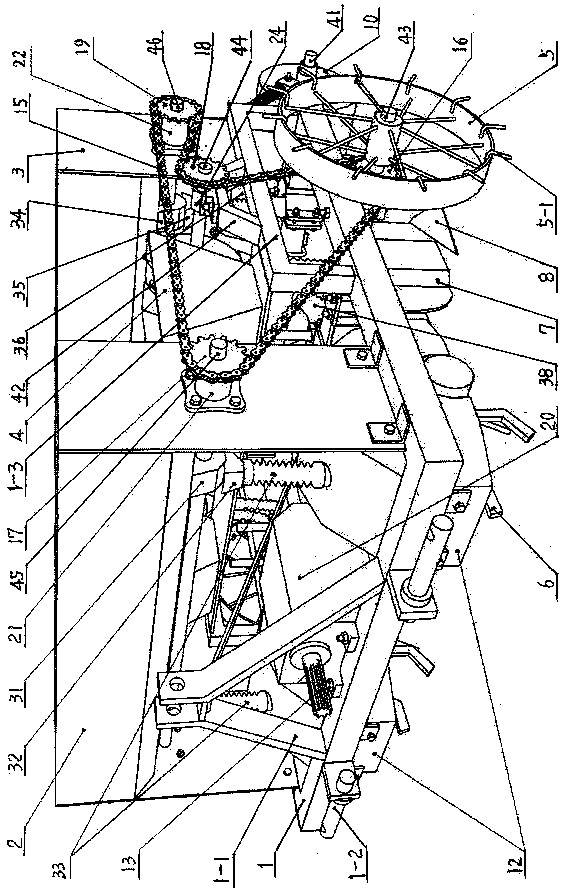

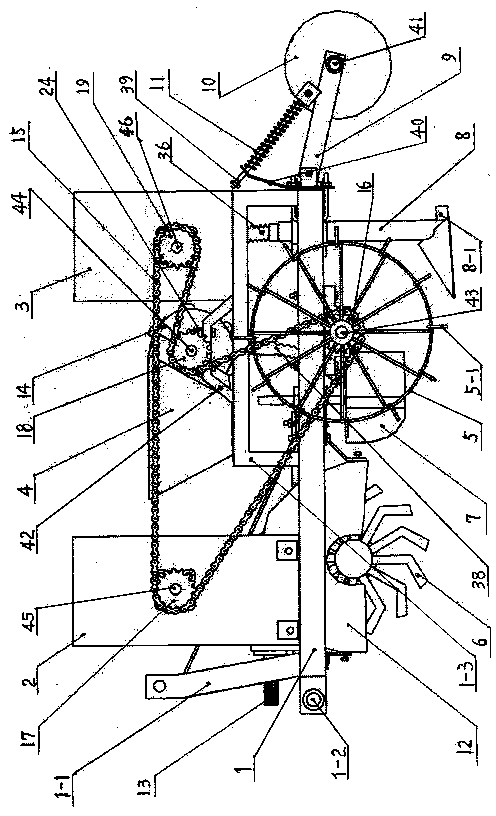

[0011] Examples, see attached Figure 1~3 The two-row peanut planter on the ridge is equipped with a triangular upper traction frame 1-1 above the front beam of the main frame 1, and two horizontal lower traction frames are symmetrically arranged on the front beam of the main frame 1. Rack 1-2. The front fertilizer box 2 is fixed on the front of the main frame 1, the rotary tiller gearbox 20 is fixed on the crossbeam in front of the main frame 1, and the rotary tiller 6 is installed on the both sides of the rotary tiller gearbox 20. The rotary tiller power input shaft 13 is provided in the machine gearbox 20, and the rotary tiller power input shaft 13 is connected with the tractor power output shaft. The outside of the rotary tiller 6 is provided with a rotary tiller shield 12 , and the front fertilizer delivery conduit 33 below the front fertilizer box 2 is inserted in the rotary tiller shield 12 . Fix the rear fertilizer box 3 above the back of the main frame 1, and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com