A phase shifting unit

A technology of phase shifting and dielectric board, which is applied in the direction of electrical components, circuits, waveguide devices, etc., and can solve the problems of large line loss and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

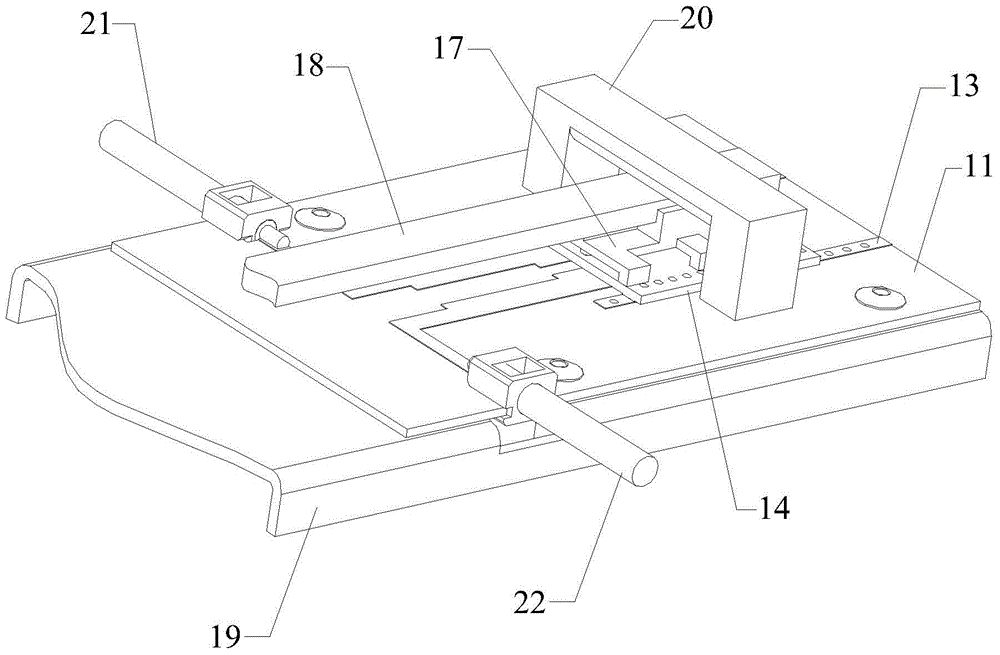

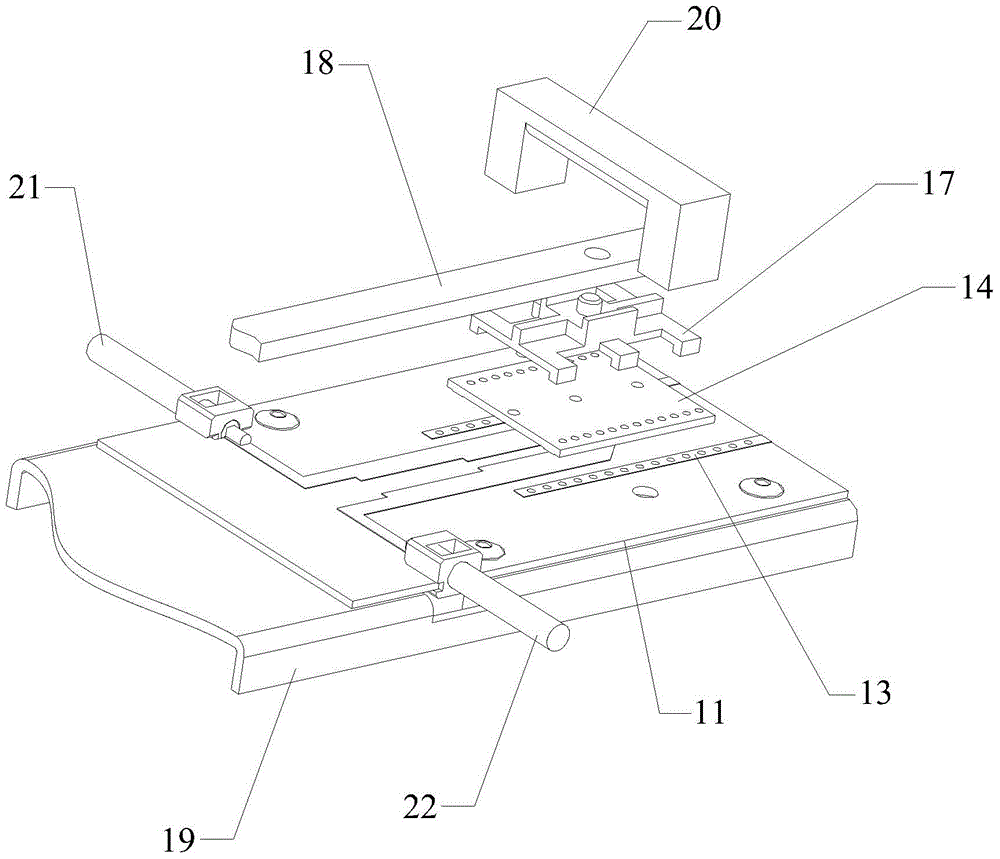

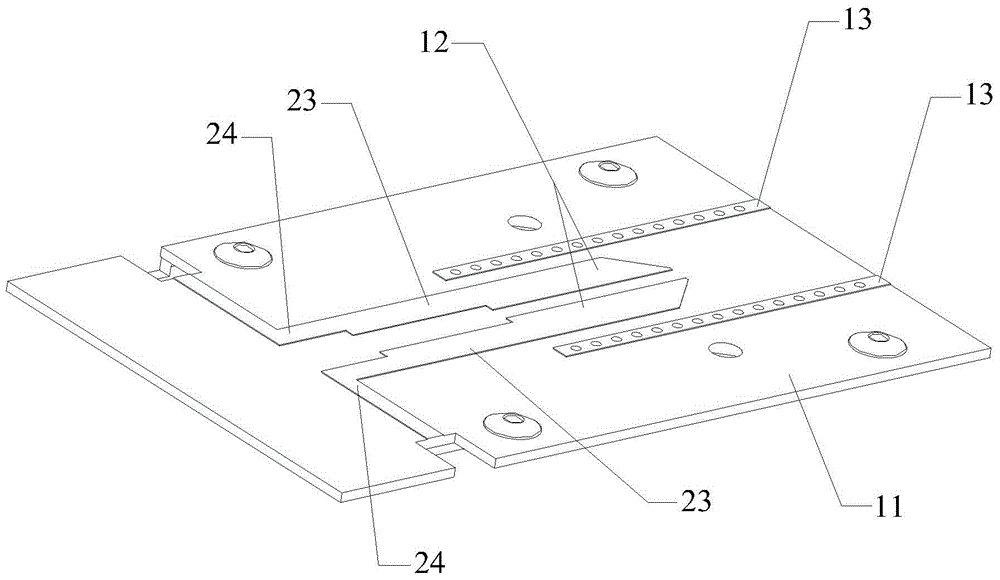

[0031] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , figure 1 is a schematic structural diagram of an embodiment of the phase shifting unit of the present invention, figure 2 yes figure 1 An exploded view of the phase-shifting unit shown, Figure 3-5 yes figure 1 The schematic diagram of the local structure of the phase-shifting unit shown, such as Figure 1-5 As shown, the phase shifting unit includes: a first dielectric plate 11, a parallel conductor strip 12, a first metal ground (not shown), a first ground strip 13, a second dielectric plate 14, a U-shaped conductor strip 15, a second metal ground A ground (not shown in the figure), a second ground strap 16 , a connecting piece 17 , a pull rod 18 , a mounting plate 19 , a pressing piece 20 , an input port 21 and an output port 22 .

[0032] Wherein, the phase shifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com