Rotation variable pitch test stand

A technology of a test bench and a rotating platform, applied in the field of driving equipment testing, can solve the problem that the operation mode of the pitch mechanism cannot be truly reflected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following examples are used to further describe the present invention in detail.

[0021] Since the actual wind power blade is disturbed by the wind speed during the rotation process, the blade load changes and then affects the motor pitch system, so a core idea of the present invention is to introduce a rotating mechanism in the pitch test platform, thereby Realistically simulate the actual operation of the pitch mechanism.

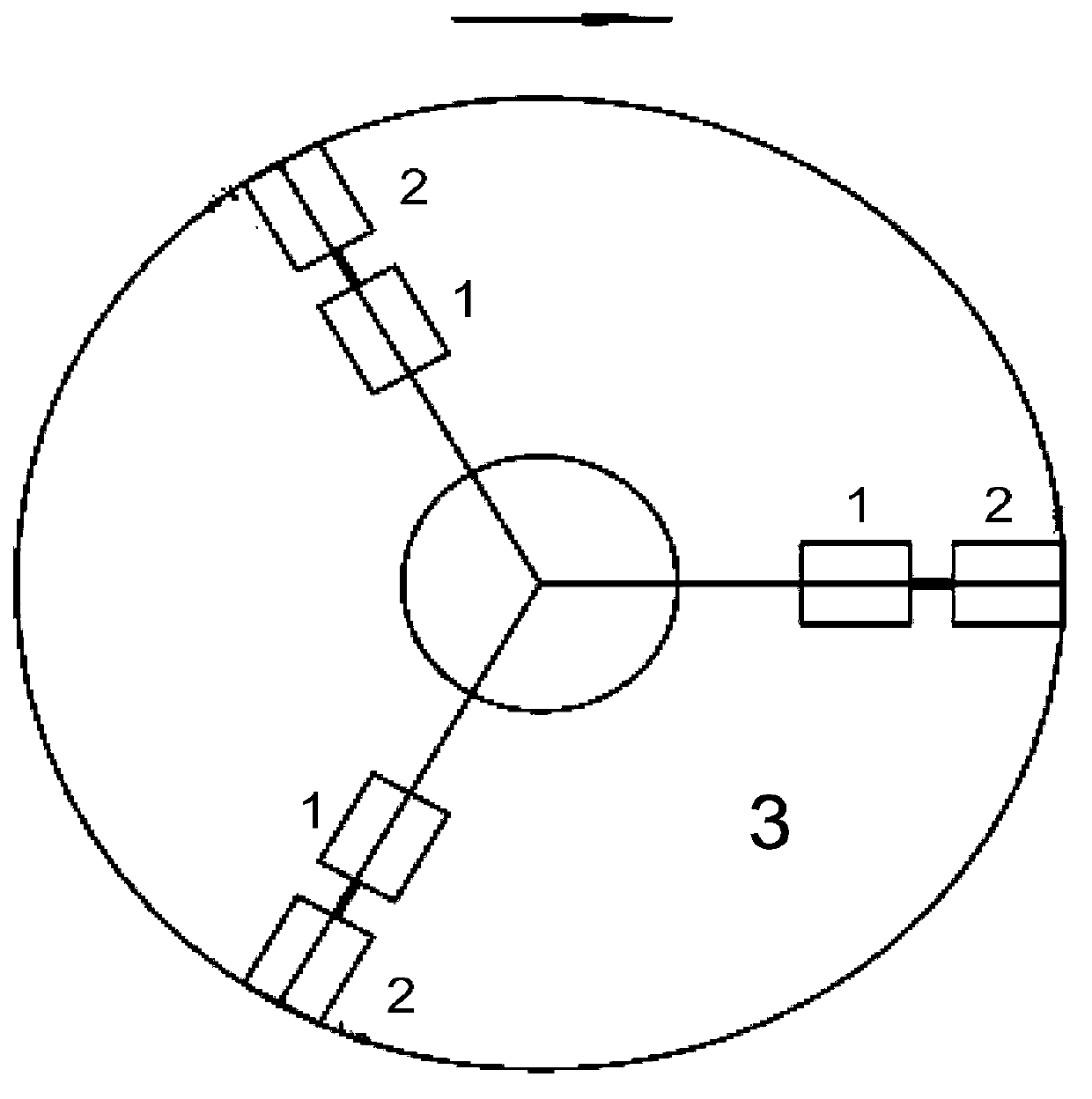

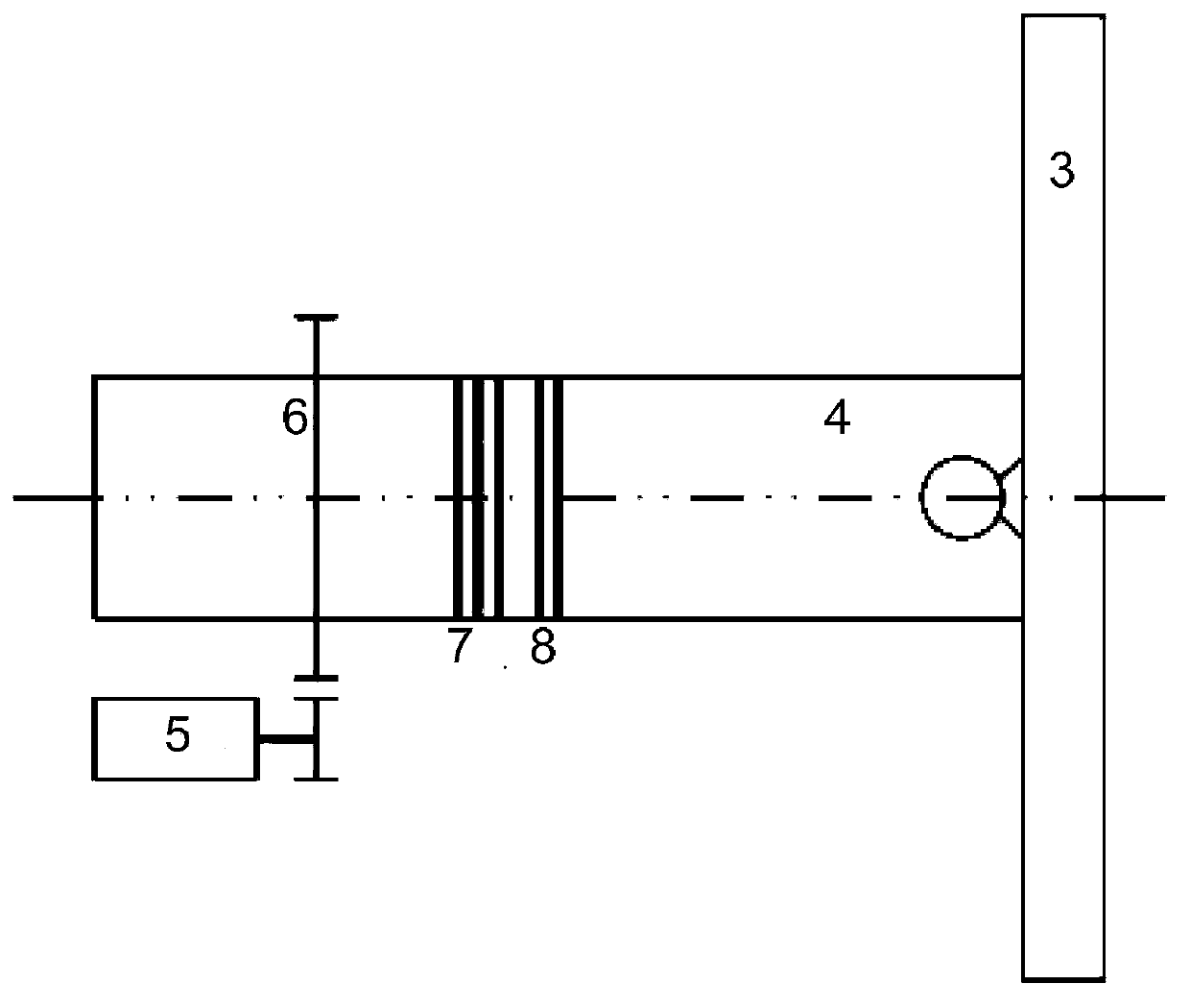

[0022] In the pitch test bench of the specific embodiment of the present invention, such as figure 2 As shown, including the pitch motor 1 and the load motor 2 in the original test bench, in addition, the pitch test bench also includes a rotating mechanism, the rotating mechanism includes a rotatable rotating platform 3, the pitch motor 1 and the load motor 2 are arranged on one side of the rotating platform 3 . The connection between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com