A lighting system for led vertical freezer

A lighting system and LED chip technology, applied in the field of lighting systems, can solve the problems of shortened service life of the LED lighting system, lack of a sealing structure, and the LED lighting system is susceptible to water and moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

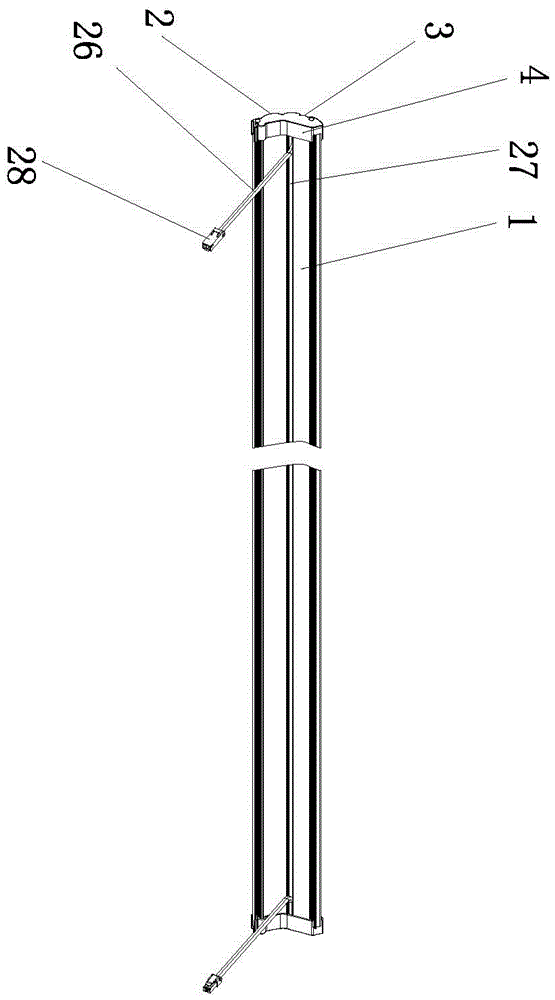

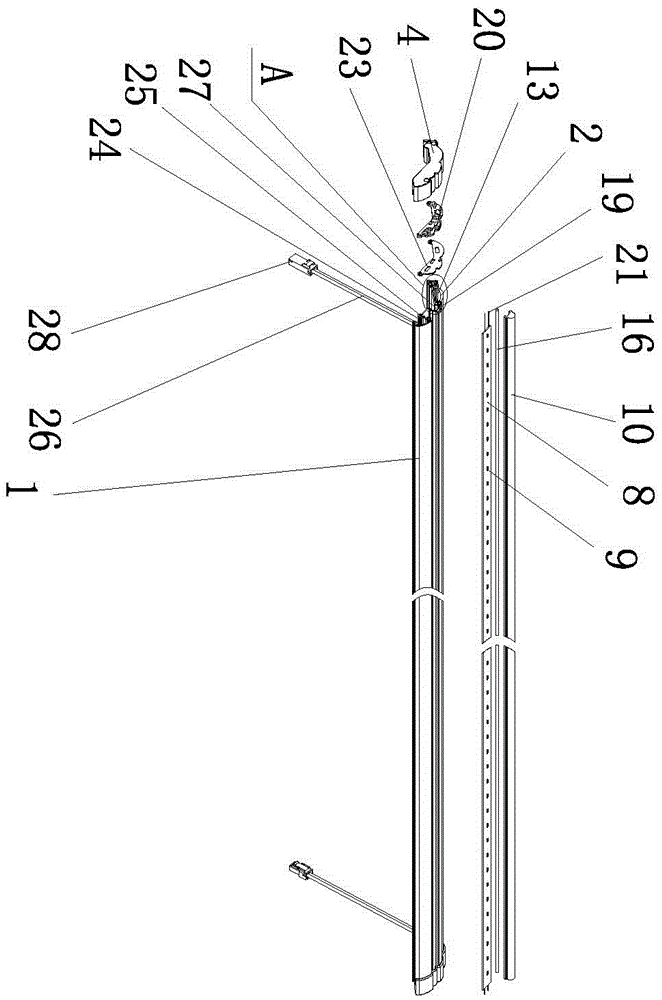

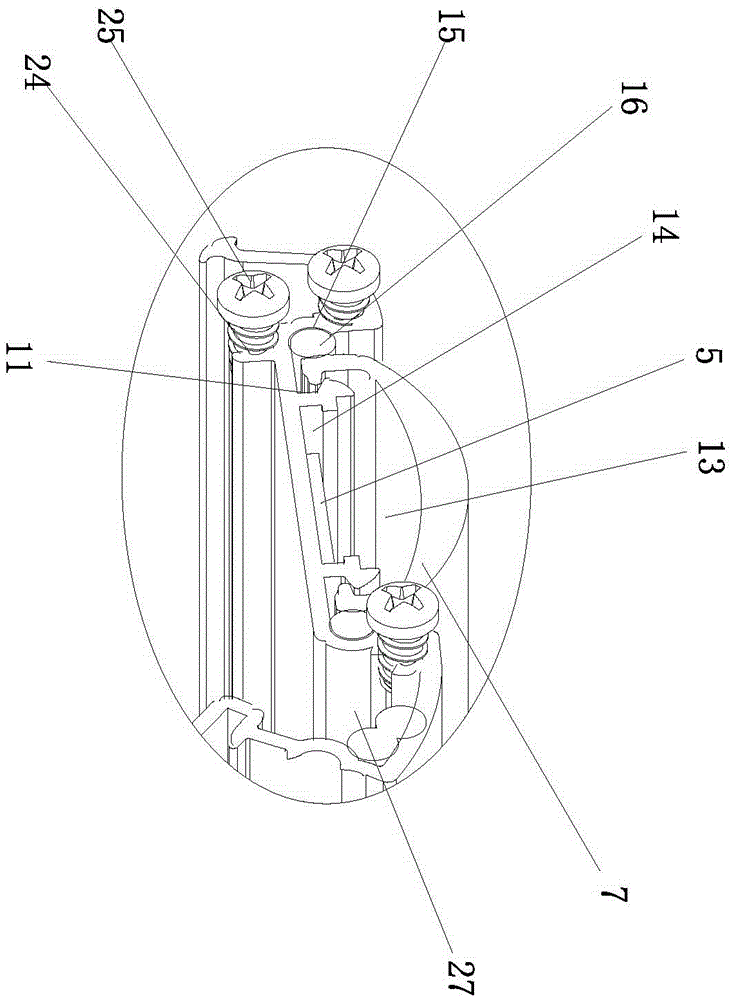

[0021] refer to Figure 1 to Figure 6 , the LED vertical refrigerator lighting system of the present invention includes a housing structure assembly 1, an optical system, a power supply system, and a waterproof and moisture-proof system. The optical system includes a first LED lighting assembly 2 and a second LED lighting assembly 3. The first The LED lighting assembly 2 includes a first substrate 5, a first LED chip 6, and a first lens plate 7, and the second LED lighting assembly 3 includes a second substrate 8, a second LED chip 9, and a second lens plate 10. The surface of the body structure component 1 is provided with a first slide groove 11 and a second slide groove 12 along the length direction of the shell structure component 1, and the first lens plate 7 is connected with the first slide groove 11 and forms a second An accommodating cavity 13, a first card slot 14 is provided in the first accommodating cavity 13, the first substrate 5 is set in the first card slot 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com