cementing ball seat

A ball seat and cementing technology, which is used in wellbore/well components, wellbore/well valve devices, earth-moving drilling, etc., can solve the problems of floating hoop impact, damage, affecting the performance of floating hoop, etc. The effect of using coefficients and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] The implementation of the present invention will be described in detail below in conjunction with specific embodiments.

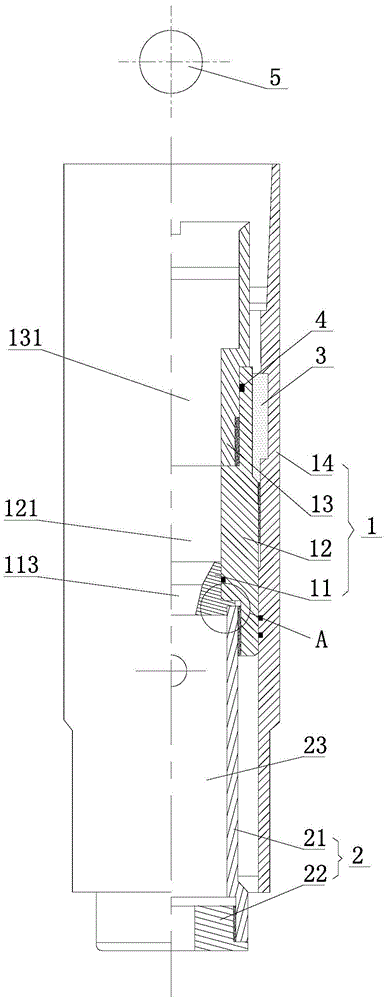

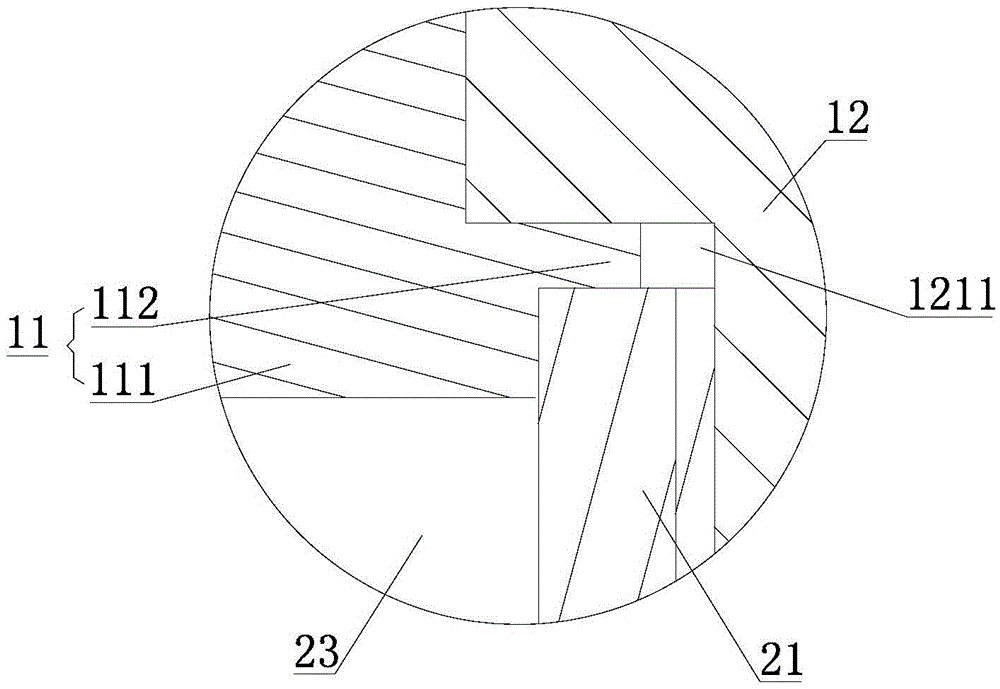

[0029] Such as figure 1 As shown, the cementing ball seat provided in this embodiment includes a ball seat main body 1 and a basketball seat 2 .

[0030] Such as figure 1 As shown, the ball seat main body 1 has a tubular shape as a whole, and the ball seat main body 1 includes a shear seat 11 which is hollow inside and has openings at both ends. The shear seat 11 is used to cooperate with the outer sphere 5 for crimping.

[0031] Such as figure 1 As shown, the basket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com