Method and device for automatically carrying out thermoregulation control on molding mould of I.S. machine

A molding mold and control method technology, applied in glass molding, electrical program control, program control in sequence/logic controller, etc., can solve the problem of no systematic record of glass mold temperature curve changes, etc., to reduce defects and stabilize Effect of molding temperature and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

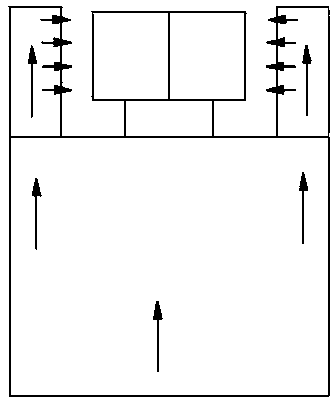

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

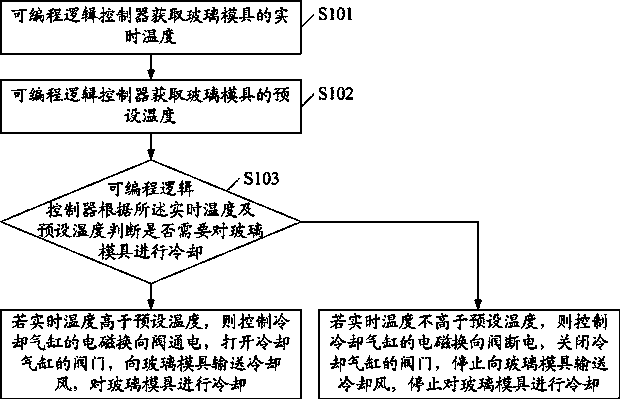

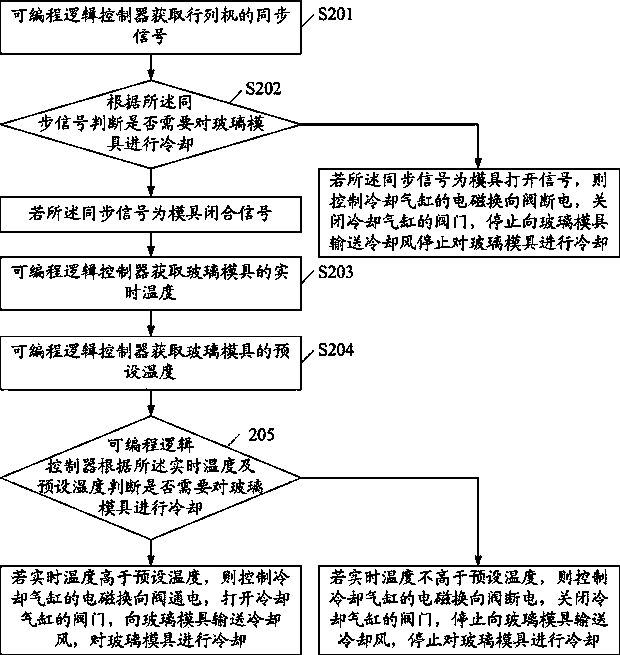

[0037] figure 2 It is a structural schematic diagram of the first embodiment of the automatic temperature regulation control method of the forming mold of the rank machine of the present invention, including:

[0038] S101, the programmable logic controller obtains the real-time temperature of the glass mould.

[0039] Specifically, the step that the programmable logic controller obtains the real-time temperature of the glass mold includes:

[0040] A1, the temperature measuring instrument measures the real-time temperature of the glass mould.

[0041] Preferably, the temperature measuring instrument is a K-type thermocouple, which has high sensitivity, good stability and uniformity, and strong oxidation resistance. Insert the K-type thermocouple into the cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com