Titanium dioxide-based composite film with hierarchical nano-dot structure and preparation method thereof

A titanium dioxide and composite film technology, applied in the field of hierarchical nano-dot structure titanium dioxide-based composite film and its preparation, can solve problems such as unfavorable subsequent utilization of cells, and achieve the effects of excellent photo-induced hydrophilicity, easy popularization and application, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

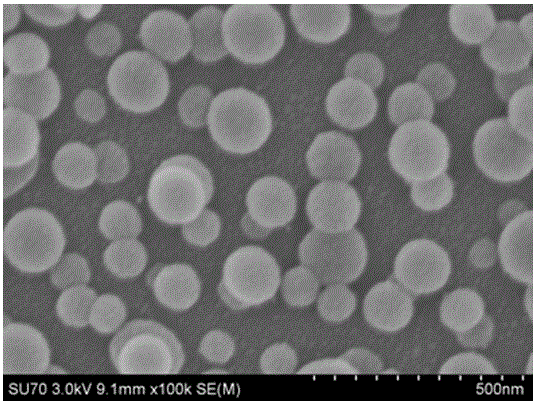

[0020] 1) Add tetrabutyl titanate, acetylacetone and deionized water into absolute ethanol at a molar ratio of 1:0.3:1, then add polyvinylpyrrolidone and stir well at room temperature to prepare a titanium atomic concentration of 0.2 M, the titanium dioxide precursor sol with a polyvinylpyrrolidone concentration of 40mg / ml; drop the titanium dioxide precursor sol onto the cleaned silicon wafer surface until it is covered, and spin coat it at a speed of 8000rpm for 40s, and then place it at 500 ℃ for 1h, a titanium dioxide nano-dot layer was obtained on the silicon wafer (see figure 1 ). It can be seen from the figure that the titanium dioxide nano-dots have a size of 30nm-200nm and a density of 3.0×10 10 / cm 2 .

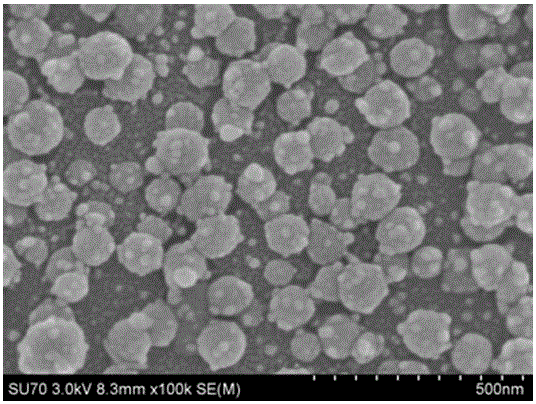

[0021] 2) Add zinc acetate and ethanolamine to absolute ethanol at a molar ratio of 1:1, stir well at room temperature, and prepare a zinc oxide precursor sol with a zinc atomic concentration of 0.14M; drop the zinc oxide precursor sol to Step 1) The prepared tit...

Embodiment 2

[0024] 1) Add titanium tetrachloride, acetylacetone, and deionized water to absolute ethanol at a molar ratio of 1:0.3:1, then add polyvinylpyrrolidone and stir well at room temperature to prepare a titanium atomic concentration of 0.1 M , a titanium dioxide precursor sol with a polyvinylpyrrolidone concentration of 10 mg / ml; drop the titanium dioxide precursor sol onto the cleaned titanium sheet surface until it is covered, and spin coat it at a speed of 8000 rpm for 60 seconds, and then place it at 600 ° C Keeping it warm for 2 hours, a titanium dioxide nano-dot layer is obtained on the titanium sheet. The titanium dioxide nano-dots have a size of 80nm-280nm and a density of 1.0×10 10 / cm 2 .

[0025] 2) Add zinc nitrate and ethanolamine to absolute ethanol at a molar ratio of 1:1, stir well at room temperature, and prepare a zinc oxide precursor sol with a zinc atomic concentration of 0.2M; drop the zinc oxide precursor sol to Step 1) The prepared titanium dioxide nano-d...

Embodiment 3

[0027] 1) Add titanium trichloride, ethanolamine, and deionized water to absolute ethanol at a molar ratio of 1:0.3:1, then add polyvinylpyrrolidone and stir well at room temperature to prepare a titanium atomic concentration of 0.5 M, Titanium dioxide precursor sol with a polyvinylpyrrolidone concentration of 60mg / ml; drop the titanium dioxide precursor sol onto the cleaned titanium-nickel alloy sheet surface until it is covered, and spin-coat at a speed of 4000rpm for 20s, and then place it at 400 The temperature is kept at ℃ for 1 h, and a titanium dioxide nano-dot layer is obtained on the titanium-nickel alloy sheet. The titanium dioxide nano-dots have a size of 100nm to 300nm and a density of 1.0×10 10 / cm 2 .

[0028] 2) Add ferric nitrate and acetylacetone to absolute ethanol at a molar ratio of 1:2, stir well at room temperature, and prepare an iron oxide precursor sol with an iron atomic concentration of 0.02M; drop the iron oxide precursor sol To the titanium diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com