A polyhedral structure for the lower head

A polyhedral structure, polyhedral technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of limited number of positioners, high manufacturing cost, low production efficiency, etc., to ensure welding quality, reduce Production cost, the effect of providing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

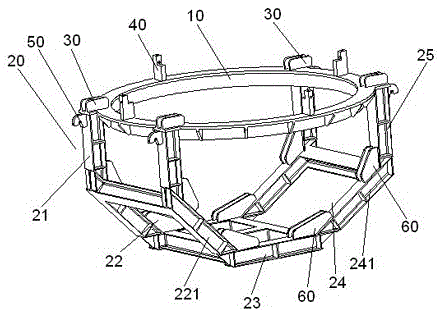

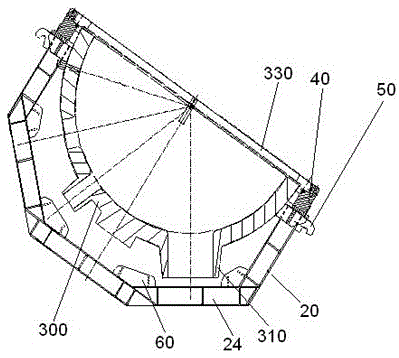

[0038] Such as figure 1 As shown, a polyhedral structure used for the lower head, the polyhedral structure includes: a polyhedral bracket 20 , a support ring 10 , two pairs of connectors 30 , multiple stops 40 and two pairs of hooks 50 .

[0039] The support ring 10 is connected to the top of the polyhedron support 20; one end of each pair of connectors 30 is respectively arranged on the support ring 10, and the other end of the pair of connectors 30 is respectively arranged on the top of the polyhedron support 20; a plurality of stoppers 40 are evenly and symmetrically arranged On the support ring 10 ; two pairs of hooks 50 are respectively arranged on the polyhedron bracket 20 .

[0040] In this embodiment, the section of each connecting piece 30 is "H" shaped. Each stopper 40 has an “L”-shaped cross section,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com