Indoor assembled ventilated grain storage bin

A grain storage bin and assembly type technology, applied in the field of storage devices, can solve the problems of waste, grains are susceptible to moisture and mildew, and achieve the effects of preventing mildew and rot, and facilitating installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

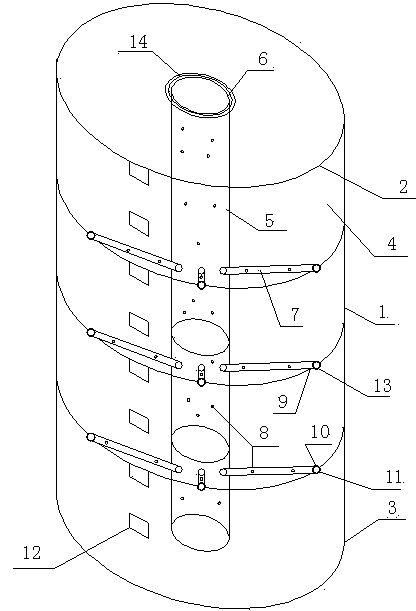

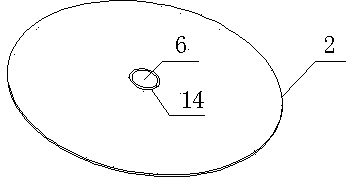

[0030] An indoor assembled ventilated grain storage silo, comprising a silo body 1 and a silo cover 2, the silo body 1 is composed of a silo bottom 3 and a cylinder 4, the silo bottom 3 is vertically movably connected with a main road ventilation pipe 5, and the silo cover 2 has a Air hole 6, the main road ventilation pipe 5 is matched with the air hole 6, the side wall of the main road ventilation pipe 5 is vertically movably connected with a branch ventilation pipe 7, and the main road ventilation pipe 5 and the branch ventilation pipe 7 are provided with ventilation holes 8 , The cylinder 4 is provided with a pipe hole 9 for the passage of the branch air pipe 7 .

Embodiment 2

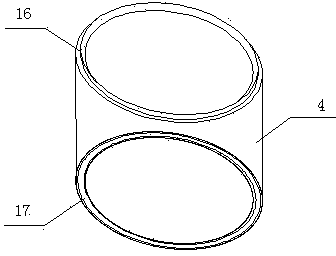

[0032] An indoor assembled ventilated grain storage silo, comprising a silo body 1 and a silo cover 2, the silo body 1 is composed of a silo bottom 3 and a cylinder 4, the silo bottom 3 is vertically movably connected with a main road ventilation pipe 5, and the silo cover 2 has a Air hole 6, the main road ventilation pipe 5 is matched with the air hole 6, the side wall of the main road ventilation pipe 5 is vertically movably connected with a branch ventilation pipe 7, and the main road ventilation pipe 5 and the branch ventilation pipe 7 are provided with ventilation holes 8 , The column body 4 is provided with a tube hole 9 for the passage of the branch air pipe 7, and the column body 4 is composed of 2-9 joints with a height of 0.4 m -0.8 m.

Embodiment 3

[0034] An indoor assembled ventilated grain storage silo, comprising a silo body 1 and a silo cover 2, the silo body 1 is composed of a silo bottom 3 and a cylinder 4, the silo bottom 3 is vertically movably connected with a main road ventilation pipe 5, and the silo cover 2 has a Air hole 6, the main road ventilation pipe 5 is matched with the air hole 6, the side wall of the main road ventilation pipe 5 is vertically movably connected with a branch ventilation pipe 7, and the main road ventilation pipe 5 and the branch ventilation pipe 7 are provided with ventilation holes 8 , the cylinder 4 is provided with a tube hole 9 for the passage of the branch air pipe 7, the column 4 is composed of 2-9 joints, each section has a height of 0.4 m-0.8m, and the tube hole 9 is formed by the upper cylinder The bottom edge and the top edge of the lower cylinder are composed of an inwardly recessed upper groove 10 and a lower groove 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com