Handle assembly for controlling clutch of farming machine

A clutch and farming machine technology, applied in the field of farming machines, can solve the problems of poor reliability, short service life, cumbersome installation, etc., and achieve the effect of long service life, simple and compact structure, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

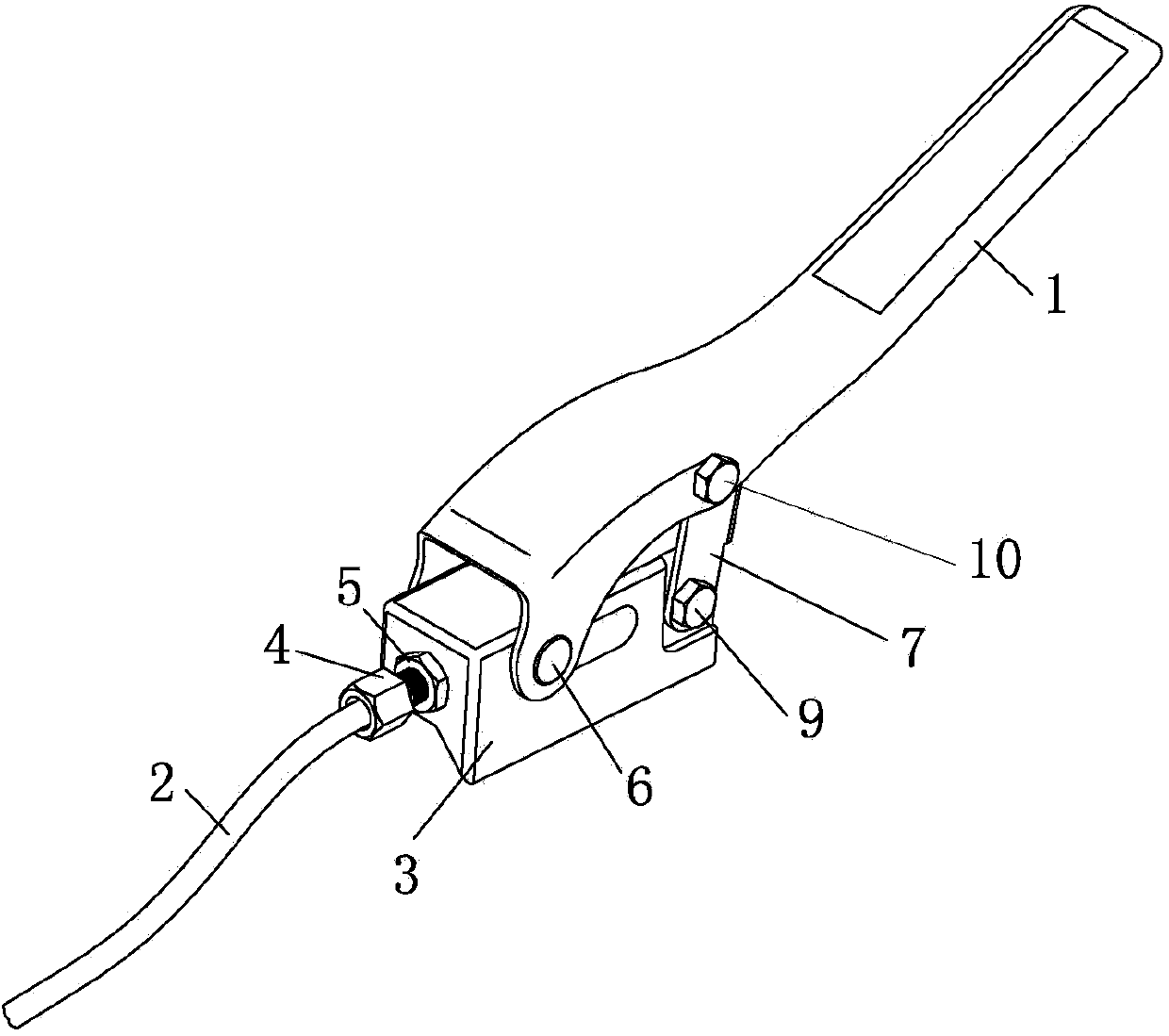

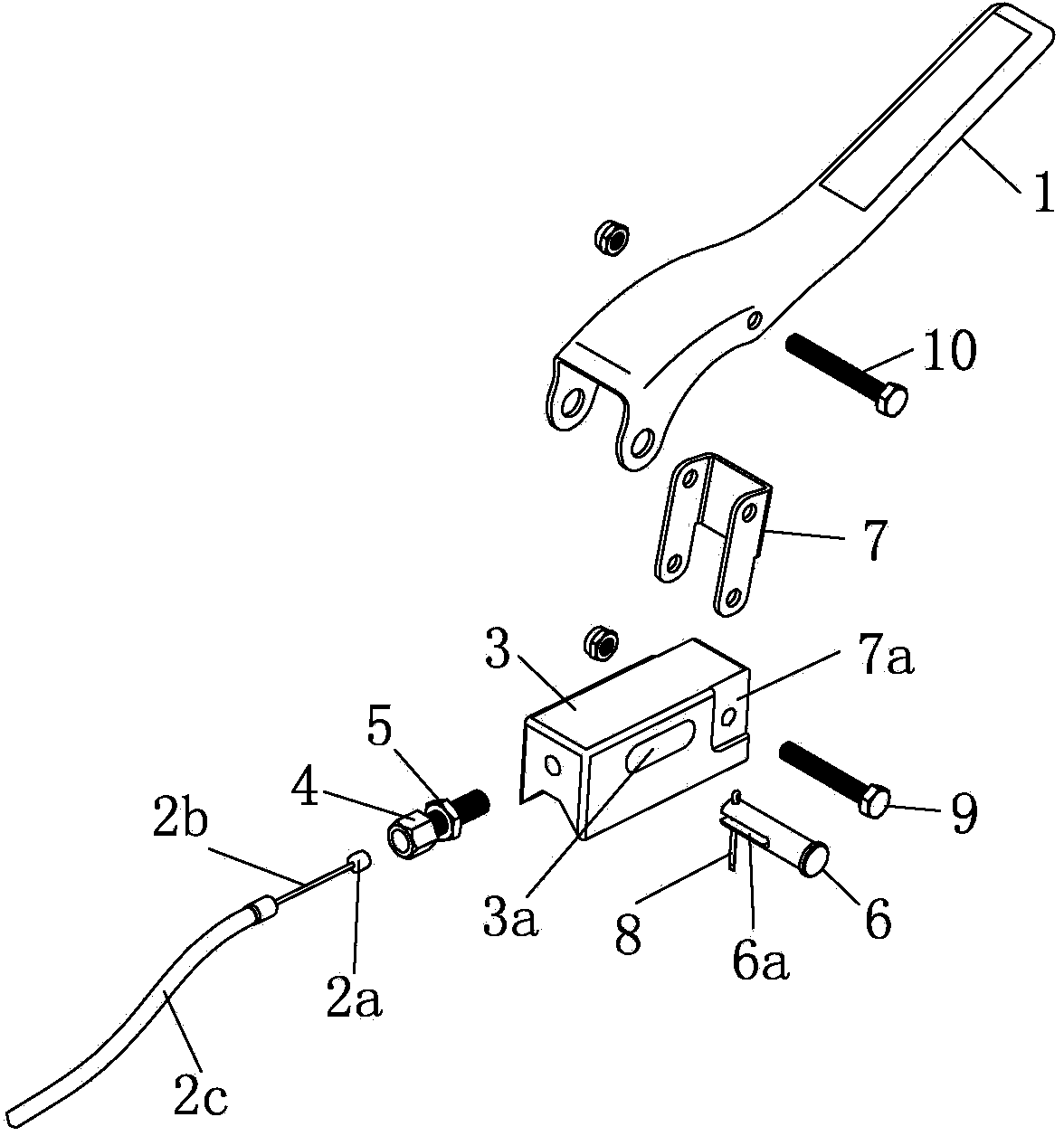

[0016] combine figure 1 —— figure 2 As shown, a handle assembly for controlling the clutch of an agricultural machine is composed of a handle 1, a clutch zipper 2, a fixing seat 3, a zipper fixing bolt 4, a zipper adjusting nut 5, a zipper fixing pin 6, a mounting bracket 7, a cotter pin 8, a second A bolt and nut assembly 9, a second bolt and nut assembly 10 and the like.

[0017] The fixing base 3 is a rectangular box structure, and the fixing base 3 is provided with a bar-shaped groove 3a extending through the left and right side walls and extending forward and backward, for installing the zipper fixing pin 6 . The zipper fixing pin 6 has an end, and the rod portion of the zipper fixing pin 6 has a gap 6a. The zipper fixing pin 6 passes through the strip groove 3a and then passes through the vertically inserted cotter pin 8 at the tail to prevent it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com