Waste tire prestressed ring assembly

A technology of waste tires and prestressing, which is applied in the direction of construction and building construction, can solve the problems of no environmental protection, energy saving, high efficiency, low cost, unsatisfactory methods, narrow application fields, etc., and achieve simple and effective recycling methods , simple structure, and the effect of reducing the amount of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

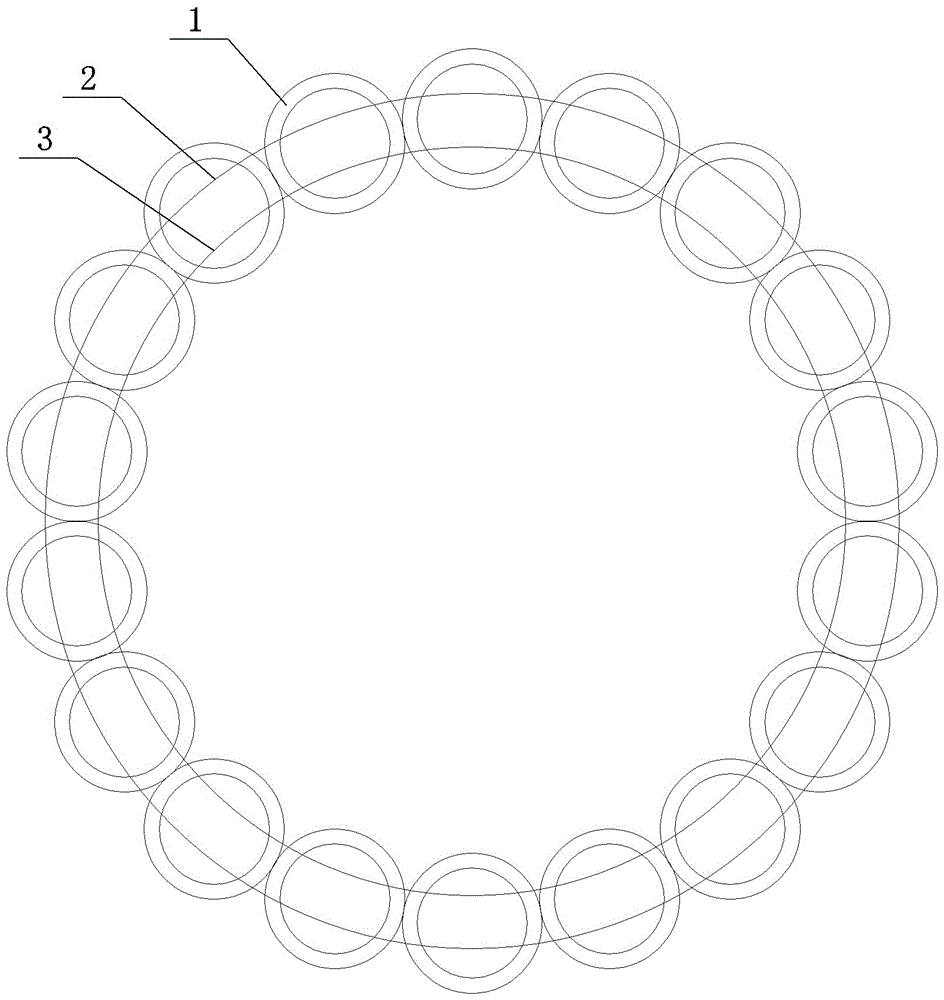

[0020] Embodiment 1: A kind of scrap tire prestressed ring assembly, see figure 1 , composed of a plurality of scrap wheels 1 to form a ring structure, and each scrap tire 1 is penetrated with an outer steel strand 2 and an inner steel strand 3 and prestressed respectively, wherein the inner steel strand 3 is prestressed The stress intensity is greater than the prestress intensity of the outer steel strand 2. Each tire is deformed due to mutual extrusion.

Embodiment 2

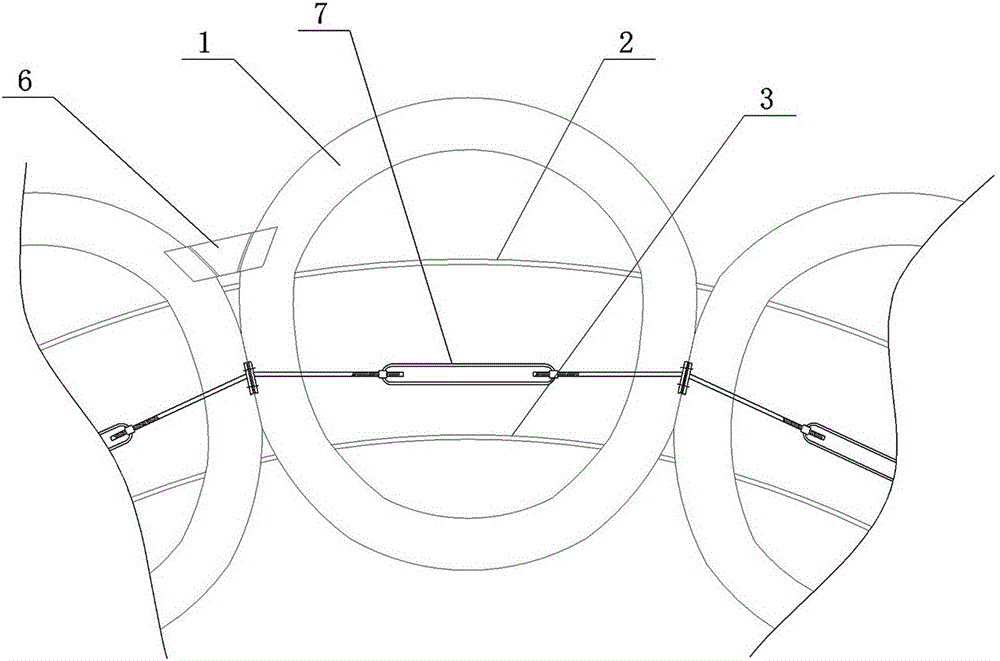

[0021] Embodiment 2: On the basis of Embodiment 1, an inner tensioner 7 is connected to the inner side of the adjoining surfaces of adjacent waste tires 1 . see figure 2 , the inner tensioner 7 is threadedly connected with a push rod at both ends of a central adjusting screw sleeve, the threads on both sides are reverse threads, the ends of the push rods on both sides are respectively provided with top feet, and the top feet on both sides are provided with Through-holes for steel strands.

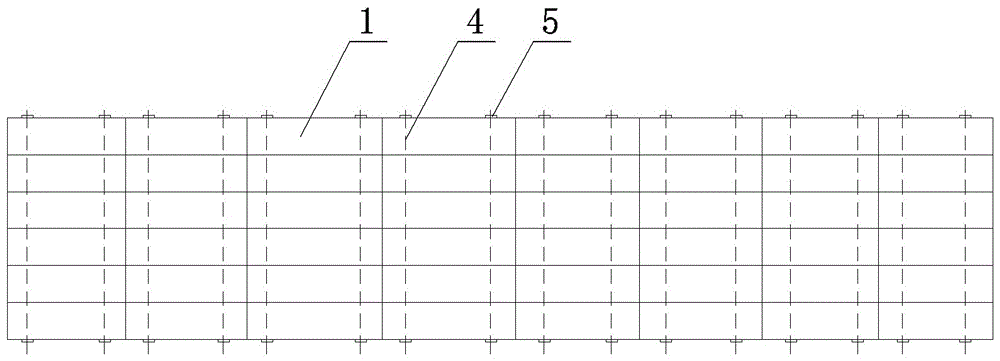

[0022] Examples 3 and 4: see respectively image 3 and Figure 4 After the multi-layer prestressed ring assembly is superimposed up and down, the axial steel strand 4 is penetrated and fixed and prestressed to form a prestressed ring three-dimensional structure. image 3 It is a consistent superposition structure up and down, Figure 4 It is a downward dislocation superposition structure.

Embodiment 5

[0023] Embodiment 5: On the basis of Embodiment 1 or Embodiment 2, in order to prevent the single-layer circular ring assembly from being bent and up and down during the pulling process of the annular prestressed steel strand, a There is a shaped part 6 for keeping adjacent waste tires from being dislocated up and down. see Figure 5 , The shaped part includes upper and lower panels 61 and webs 62, and fixing holes 63 are respectively arranged on the upper and lower panels. Be fixed on the side of waste tire 1 by bolt or rivet in the fixing hole 63 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com