Automatic-locating continuous pushing device for large box beams

A technology of automatic positioning and jacking devices, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of long hoisting equipment period, increased construction cost, and restriction of jacking efficiency, so as to reduce potential safety hazards and save energy. Construction cost, the effect of increasing the pushing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment and accompanying drawing, the present invention is described in more detail;

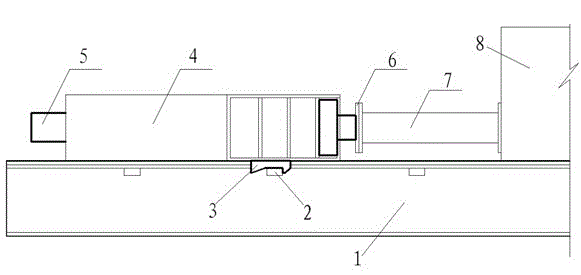

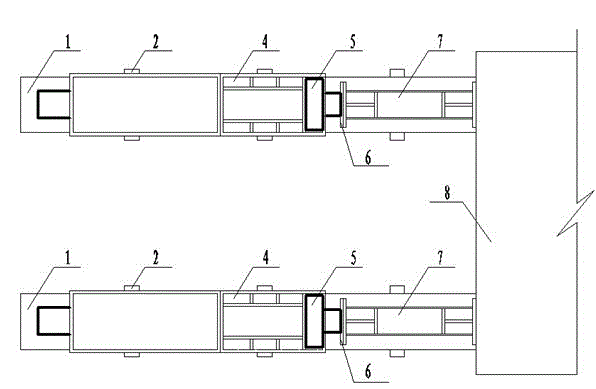

[0012] According to the length of the jacking stroke, three groups of wedge-shaped reaction seats (2) are symmetrically fixed and installed on the inner and outer sides of the double-track slideway (1) along the same distance and the same cross-section along the pushing direction, respectively, and are symmetrically fixed and installed on the lower part of the pushing bracket (4). The positioning slots (3), the positioning slots (3) are respectively engaged with the wedge-shaped reaction seat (2), the jacks (5) are respectively set in the pushing brackets (4), and the front ends of the jacks (5) are respectively passed through the flanges The disc (6) is fixedly connected to the rear end of the buffer ejector rod (7), and the front end of the buffer ejector rod (7) is respectively fixedly connected to the box beam (8).

[0013] When using the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com