Modular multi-joint flexible robot

A robot and multi-joint technology, applied in motor vehicles, transportation and packaging, etc., can solve problems such as limited application occasions, difficult dynamic control, and reduced contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

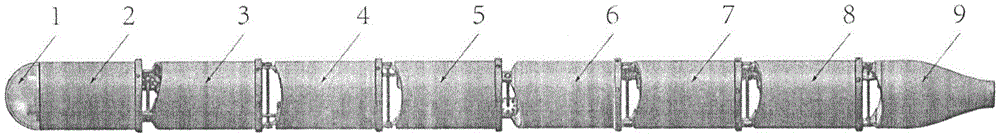

[0020] The present invention is a modular multi-joint flexible robot, such as figure 1 As shown, it includes head module 1, head cabin section 2, middle rotating module 3, middle turning module 4, middle turning module 5, middle turning module 6, middle turning module 7, middle turning module 8, tail cabin section 9, fixed Ring 10, fixed ring fixing screw 11, large swing bevel gear 12, swing motor support seat fixing bolt 13, swing motor support seat 14, small swing bevel bevel gear 15, swing motor 16, intermediate rotation module shell 17, roll motor 18 , rolling motor fixing seat 19, rolling motor fixing seat fixing bolt 20, bearing 21, rolling gear 22, rolling ring gear 23, rolling ring gear fixing ring 24, bogie connecting shaft 25, mounting plate 26, battery 27. Head camera 28, light source 29, motion control circuit 30 (including attitude senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com