Thread machining tool capable of recovering liquid waste

A thread processing and internal thread processing technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of waste of resources, decreased product processing accuracy, low work efficiency, etc., to improve processing efficiency and improve processing. Accuracy and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

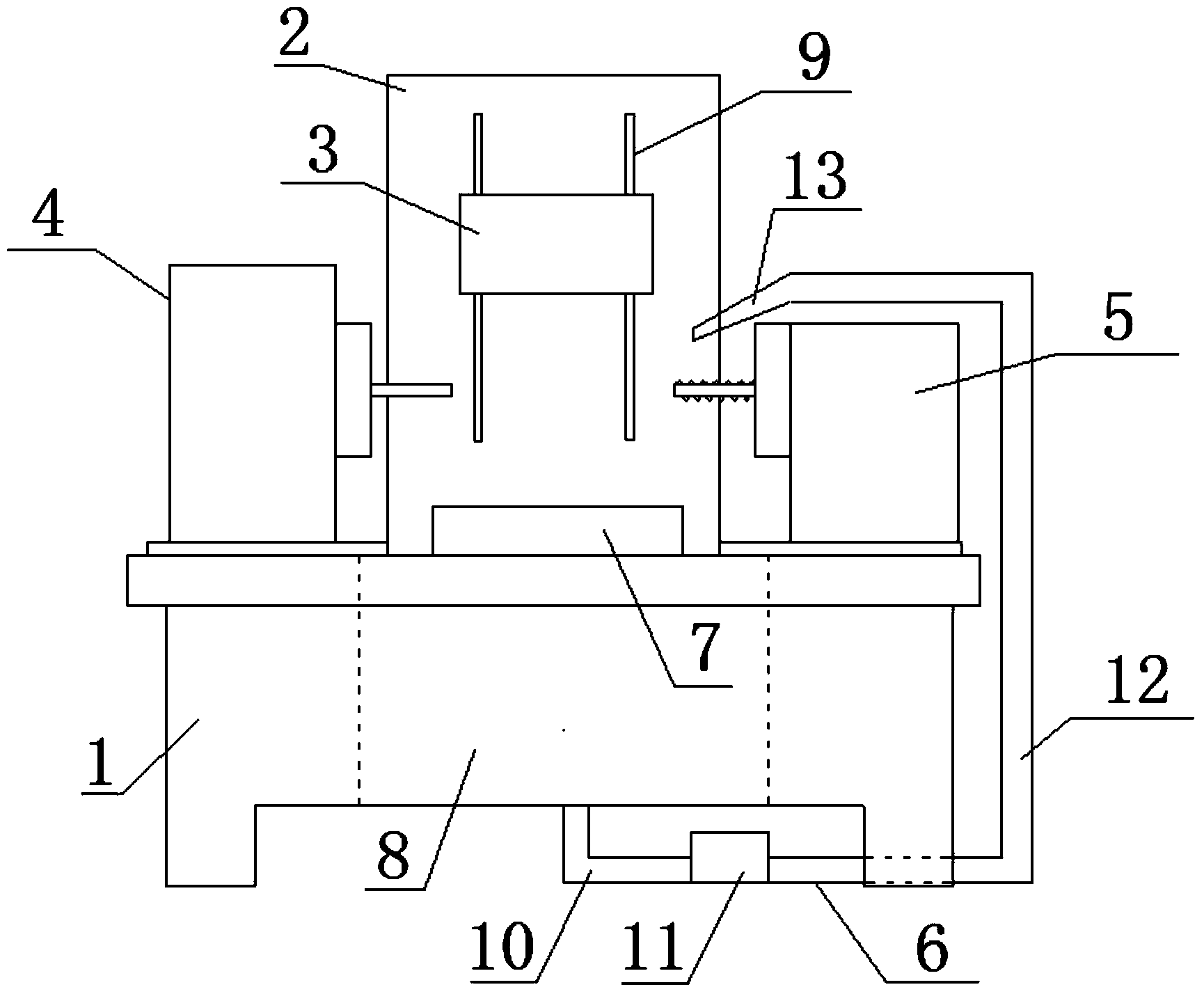

[0023] Embodiment: the workpiece is placed on the rotary table 7, the workpiece is fixed by the jacking device 3, the drilling machine 4 processes the workpiece on the rotary table 7, and after the drilling is finished, the rotary table 7 can be rotated to After drilling, the drilled hole is rotated to 5 places of the internal thread processing device for tapping, so that one machine tool can perform drilling and tapping at the same time, improving production efficiency, without changing tools or machine tools, and can also improve machining accuracy. Reduce the labor intensity of operators; the waste liquid circulation device 6 can recycle the cooling liquid, realize the waste liquid reuse, improve the processing efficiency, and save resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com