Fixed-wing aircraft rudder fatigue test system

A fatigue testing and testing system technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of not being able to simulate the hydraulic pressure of the actuator, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

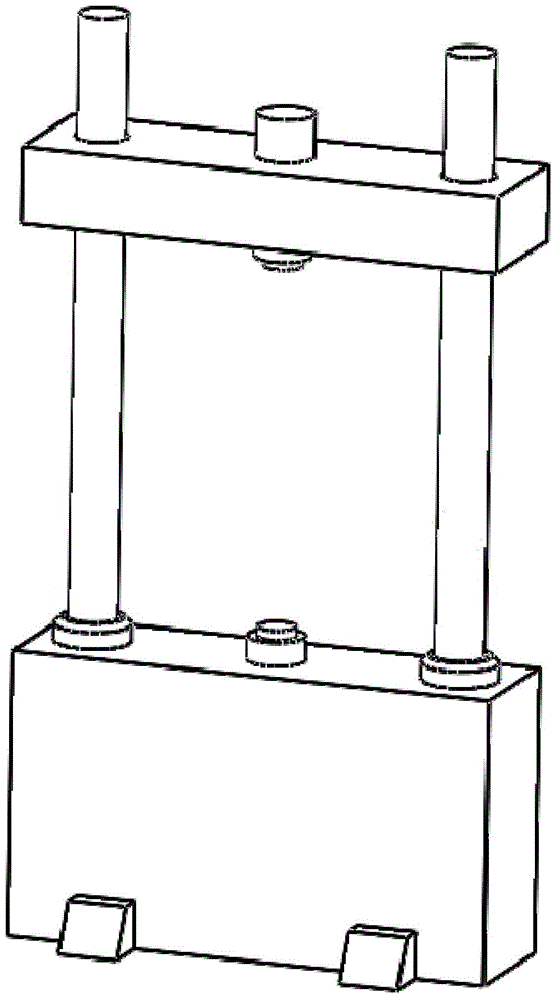

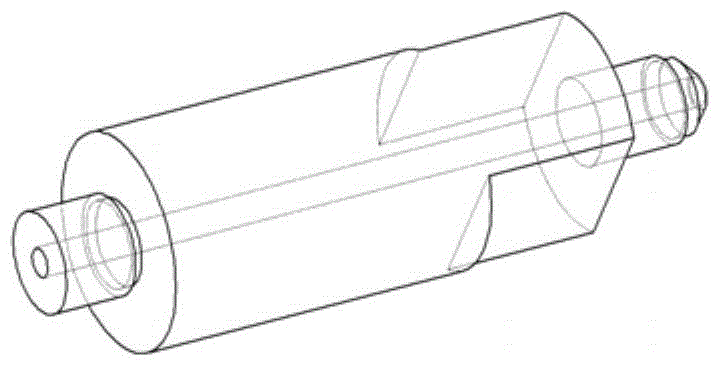

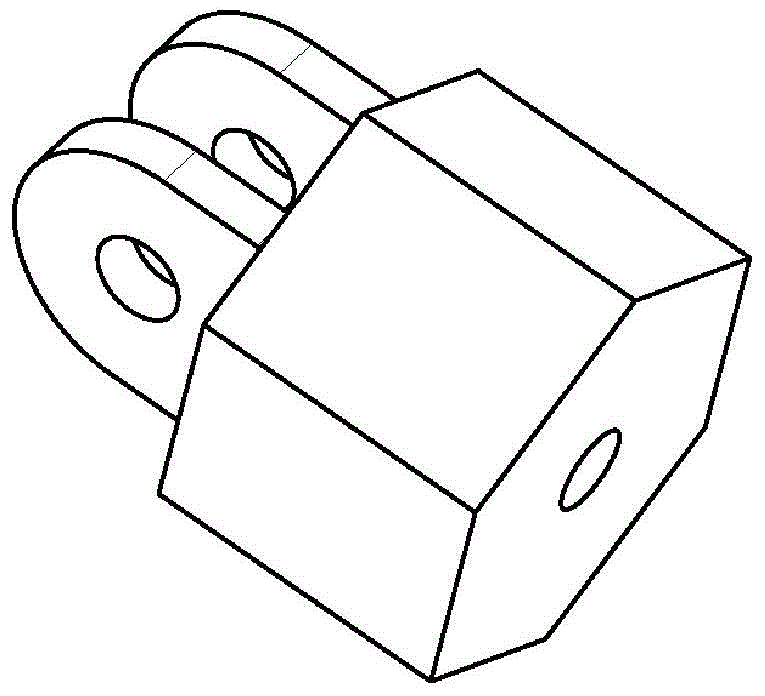

[0024] Specific implementation method: combined Figure 1 to Figure 5 Specific embodiments of the present invention will be described.

[0025] exist Figure 5 Among them, a fixed-wing aircraft rudder fatigue test system of the present invention is composed of a test bench 1, a hydraulic station 6, an actuator tester 8, a digital storage oscilloscope 7, a rotary direct drive valve 4, a pipeline conversion joint 5, and an upper connection The clamp 2, the lower connecting clamp 9, the load cell 10 and the fixed-wing aircraft rudder 3 are composed. The position connection relationship between them is as follows: the upper connecting fixture 2 and the lower connecting fixture 9 are connected with the test bench 1 through the load cell 10, the two ends of the rudder 3 of the fixed-wing aircraft are installed on the upper and lower connecting fixtures 2 and 9, and the hydraulic pressure Station 6 is connected to the rotary direct drive valve 4 through the oil pipe, and the rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com