A micro-warpage detection method for small ring parts

A detection method, a ring technology, applied to measuring devices, instruments, and optical devices, etc., can solve the problems that are not suitable for the rapid detection of small ring parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

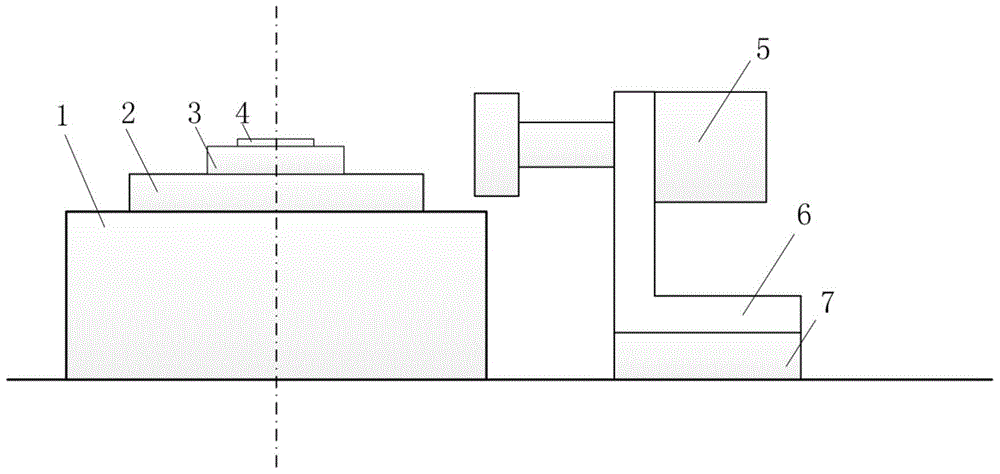

[0018] The specific implementation manner of the patent of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

[0019] For the small ring part 3 with an outer diameter of 6mm, an inner diameter of 5mm, and a thickness of 0.2mm, the micro-warpage rapid detection is performed.

[0020] Place the surface 2 on the silicon wafer as the mirror plane, and use SU-8 glue photolithography on it to make a diameter of boss. The thickness of the SU-8 glue is 0.15mm, and this part is used as the positioning column 4 when the small ring part 3 is placed.

[0021] Place the small ring part 3 on the positioning column 4, at this time, the center of the small ring part 3 coincides with the center of rotation of the rotary platform 1. Adjust the displacement platform 7, drive the industrial CCD camera 5 fixed on it to align with the gap 2 between the small ring part 3 and the mirror image placement surface, adjust the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com