Transfer robot for warehousing stereoscopic garage

A technology for handling robots and three-dimensional garages, which is applied in the field of handling robots, can solve problems such as wasting storage space, is not conducive to market promotion, and increases the cost of steel structures or concrete, so as to improve utilization, increase service life and reliability, and reduce The effect of the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Description will be made below in conjunction with the accompanying drawings.

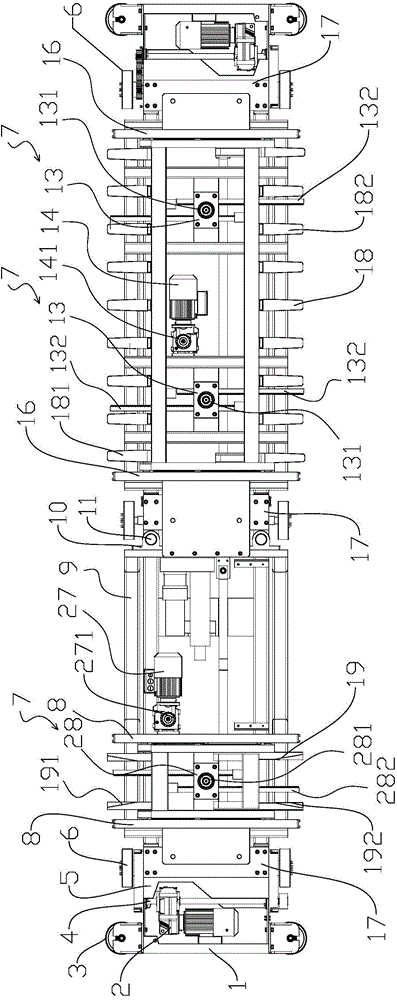

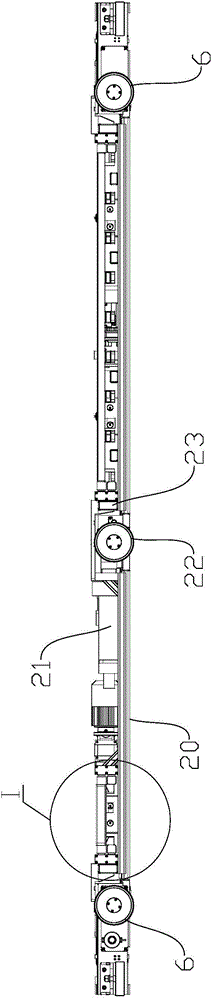

[0027] Such as figure 1 , 2 , 3, 4 shown in the three-dimensional warehouse warehouse handling robot, mainly includes front and rear moving wheels, mobile drive mechanism 1, supporting trolley chassis 20, lifting mechanism, telescopic fork type automatic centering mechanism.

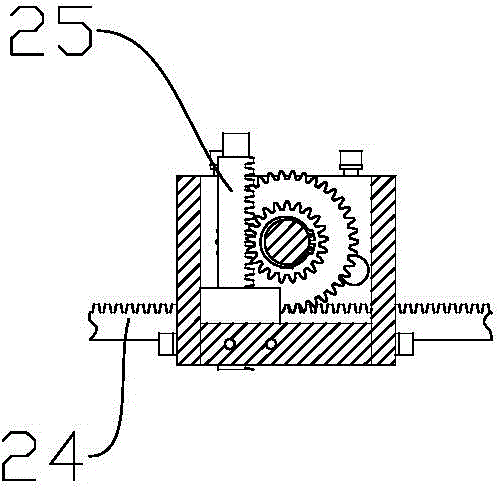

[0028] Said forward and backward movement is provided with three groups of road wheels, two groups are active road wheels, i.e. driving wheel train 6, and one group is driven road wheels, i.e. driven wheel train 22; , the right wheel that is positioned at the right side of the underframe of the supporting trolley; said two groups of active traveling wheels, that is, the driving wheel train 6, are respectively arranged at the front and rear ends of the supporting trolley underframe 20; said driven traveling wheels, that is, the driven wheel train 22 Between the two sets of drive trains 6 .

[0029] The mobile driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com