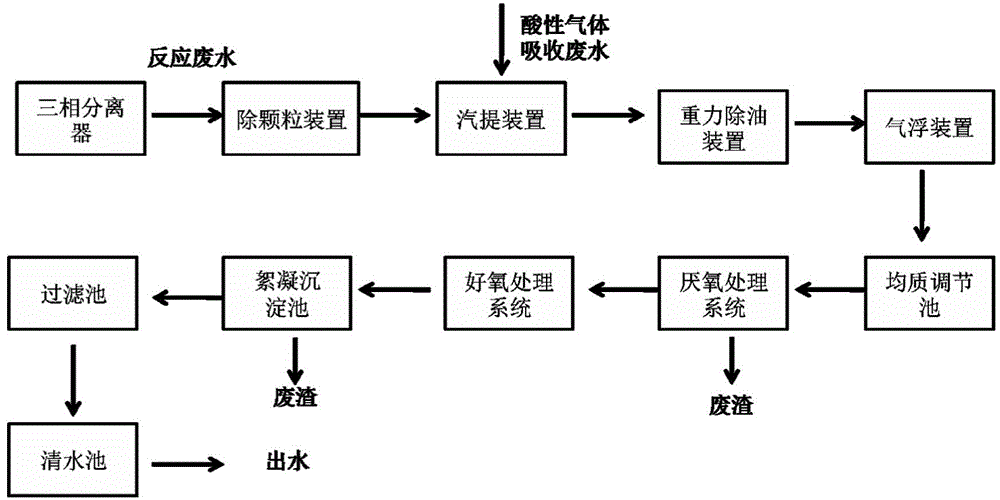

System and method for treating and recycling methanol aromatization wastewater

An aromatization and wastewater technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing treatment costs, high organic content, and reducing the dosage of chemicals Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

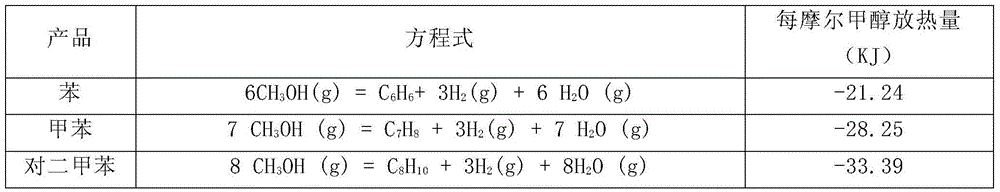

[0055]The product of methanol to aromatics process is cooled step by step to the gas, liquid and liquid three-phase separator, then enters the top of the separation tower to obtain gas phase hydrocarbons, the middle part of the separator produces oil phase substances, and the bottom of the separation tower to obtain the water phase, and the separation tower The water phase at the bottom enters the catalyst settler. After removing the solid catalyst particles, part of it is used for cooling water for MTO materials through heat exchange and cooling, and the rest enters the single stripping tower for treatment.

[0056] The temperature at the bottom of the stripper is controlled at 110°C, and the methanol content in the effluent from the bottom of the stripper is controlled below 300mg / L. The water phase produced from the bottom of the stripper is further cooled and used as the outlet of the methanol-to-aromatics reactor The material is cooled with water, and the rest continues to...

Embodiment 2

[0064] After the products of methanol to aromatics process are cooled step by step to the gas, liquid and liquid three-phase separator, gas phase hydrocarbons are obtained from the top of the separation tower, oil phase substances are produced in the middle of the separator, water phase is obtained from the bottom of the separation tower, and water phase is obtained from the bottom of the separation tower The water phase enters the solid-liquid separator, and after removing the solid catalyst particles, part of it is used as cooling water for the MTO material after heat exchange and cooling, and the remaining part enters the stripping device composed of two stripping towers for treatment.

[0065] The water phase from the bottom of the stripper is stripped. The temperature at the bottom of the first stripper is controlled at 105°C, the temperature at the bottom of the second stripper is controlled at 115°C, and the effluent from the bottom of the stripper The methanol content i...

Embodiment 3

[0073] After the products of methanol to aromatics process are cooled step by step to the gas, liquid and liquid three-phase separator, gas phase hydrocarbons are obtained from the top of the separation tower, oil phase substances are produced in the middle of the separator, water phase is obtained from the bottom of the separation tower, and water phase is obtained from the bottom of the separation tower The water phase enters the precision filter, and after removing the solid catalyst particles, part of it is used as cooling water for MTO materials through heat exchange and cooling, and the rest enters a single stripping tower for treatment.

[0074] The water phase from the bottom of the stripper is stripped, the temperature at the bottom of the stripper is controlled at 108°C, the methanol content in the effluent from the bottom of the stripper is controlled below 300mg / L, and the product produced from the bottom of the stripper is The water phase out is passed through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com