Low-Reynolds-number airfoil profile with cooperative fluidic control, and control method thereof

A low Reynolds number, cooperative jet technology, applied in the field of low Reynolds number airfoil and its control, can solve the problems of not being able to achieve the best control effect, increase the lift stall characteristics, energy supply limitations, etc., to avoid the design of the ventilation pipeline, Effects of reducing energy consumption and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

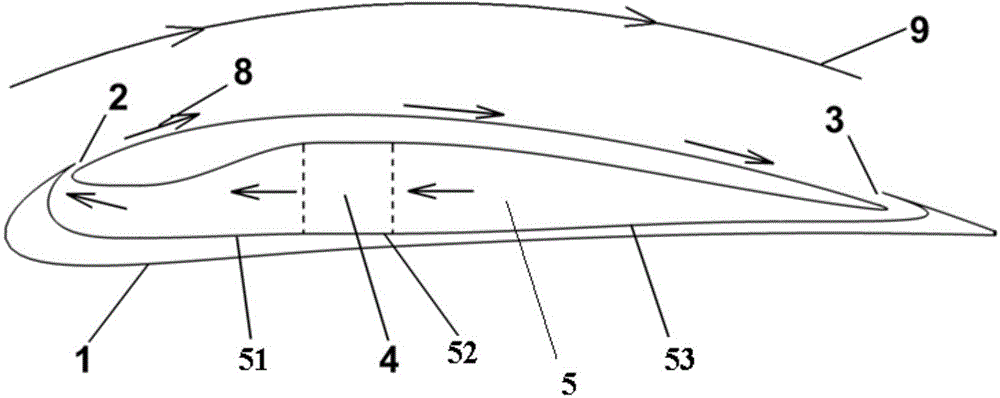

[0029] The present invention provides a low Reynolds number airfoil with cooperative jet control, such as figure 1 As shown, it is a cross-sectional view of the airfoil. The airfoil 2 is provided on the leading edge of the upper surface of the airfoil 1, and the air inlet 3 is arranged on the rear edge of the upper surface of the airfoil 2; The airflow pipeline 5 communicates with each other to form a blowing and suction circuit; an air pump 4 for driving suction and jetting at the same time is installed in the airflow pipeline 5; as a preferred method, the air injection port 2 is arranged at the position of 7.0% to 10% of the chord line , the height of the jet port 2 is 0.8% to 1.5% of the chord length; the suction port 3 is set at 80% to 88% of the chord line, and the height of the suction port 3 is 0.8% to 1.5% of the chord length. Among them, the chord line refers to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com