Solar collector header foaming rack

A technology of solar heat collectors and foam racks, which is applied in the field of solar water heater production, can solve the problems of unreasonable structure of foam racks, influence on foaming effect, poor stability, etc., achieve simple and reasonable structure, improve foaming effect, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

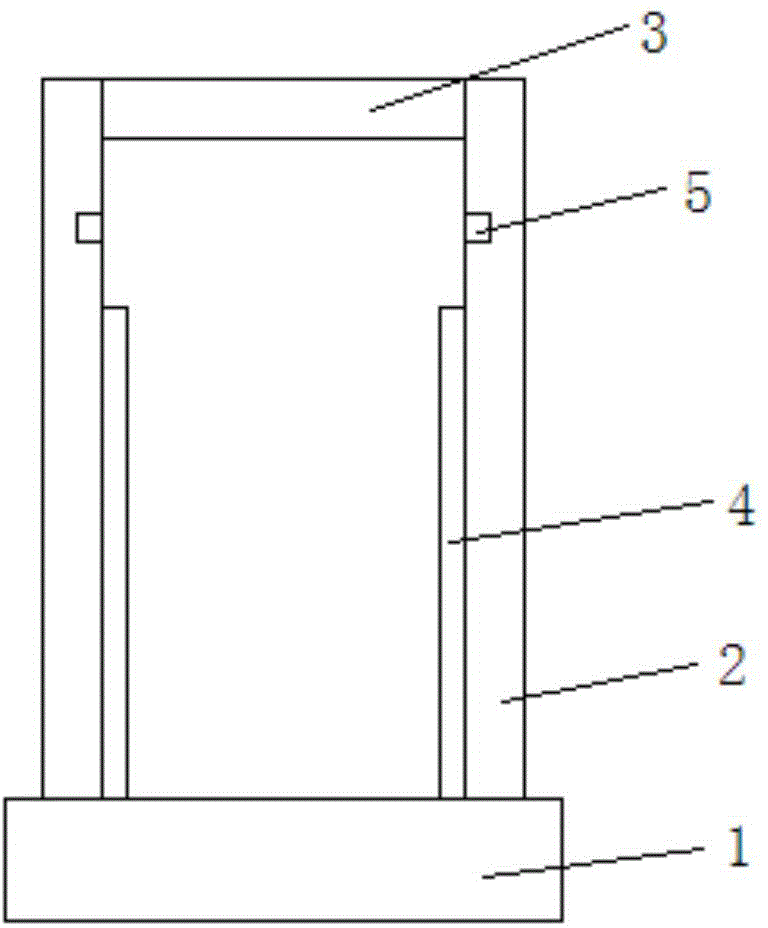

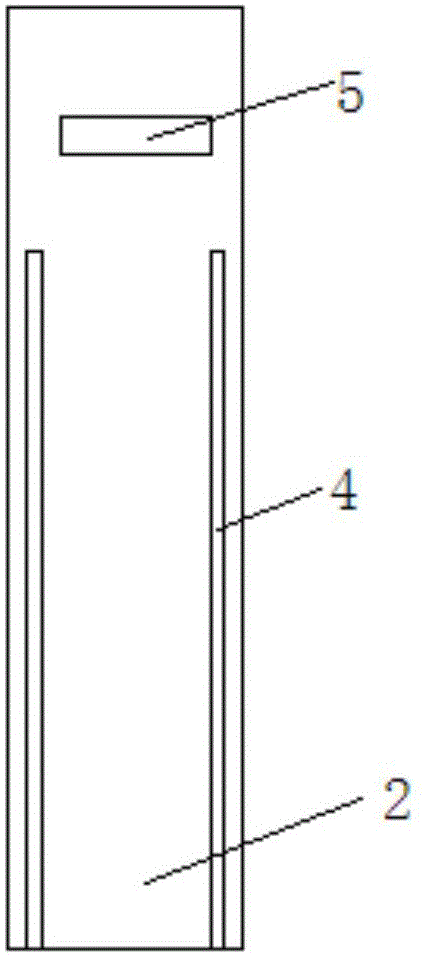

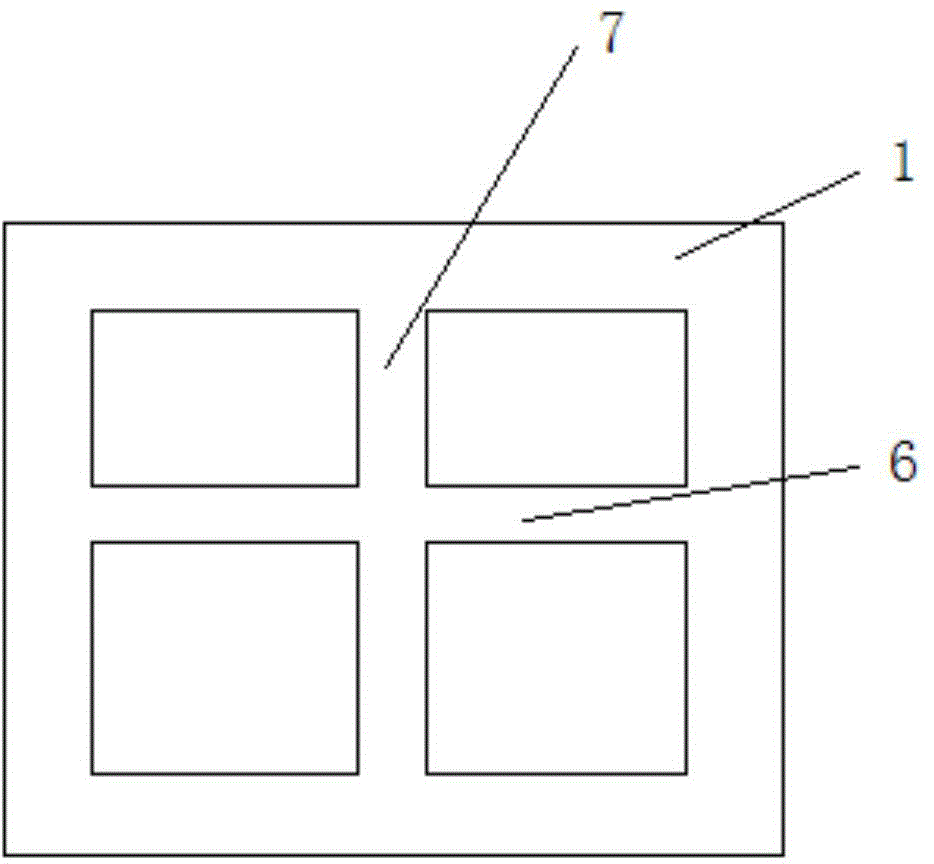

[0014] Referring to the accompanying drawings, a solar heat collector header foam frame includes a base 1 and a fixed plate 2, the fixed plate 2 is vertically arranged on both sides of the base 1, and the upper ends of the fixed plates 2 on both sides are provided with connecting rods 3, The fixed plate 2 is provided with two positioning plates 4 matched with the header. The positioning plate 4 is detachably connected with the fixed plate 2 and can be adjusted according to the size of the header. The application range is wide. The upper end of the fixed plate 2 There is a groove 5 matching with the end cover of the header. The middle of the base 1 is hollow, and the middle of the base 1 is provided with a cross bar 6 and a vertical bar 7. The cross bar 6 and the vertical bar 7 are cross-shaped, which can avoid Foaming sundries remain on the base, which ensures the stability of the header. When the solar heat collector header foam frame of the present invention is in use, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com