Automatic weighing and sorting device for lithium battery pole pieces

An automatic weighing and sorting device technology, applied in sorting and other directions, can solve problems such as low labor efficiency, affecting weighing accuracy, and high labor intensity, and achieve a high degree of mechanical automation, easy product statistics, and sorting accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawings and embodiments thereof.

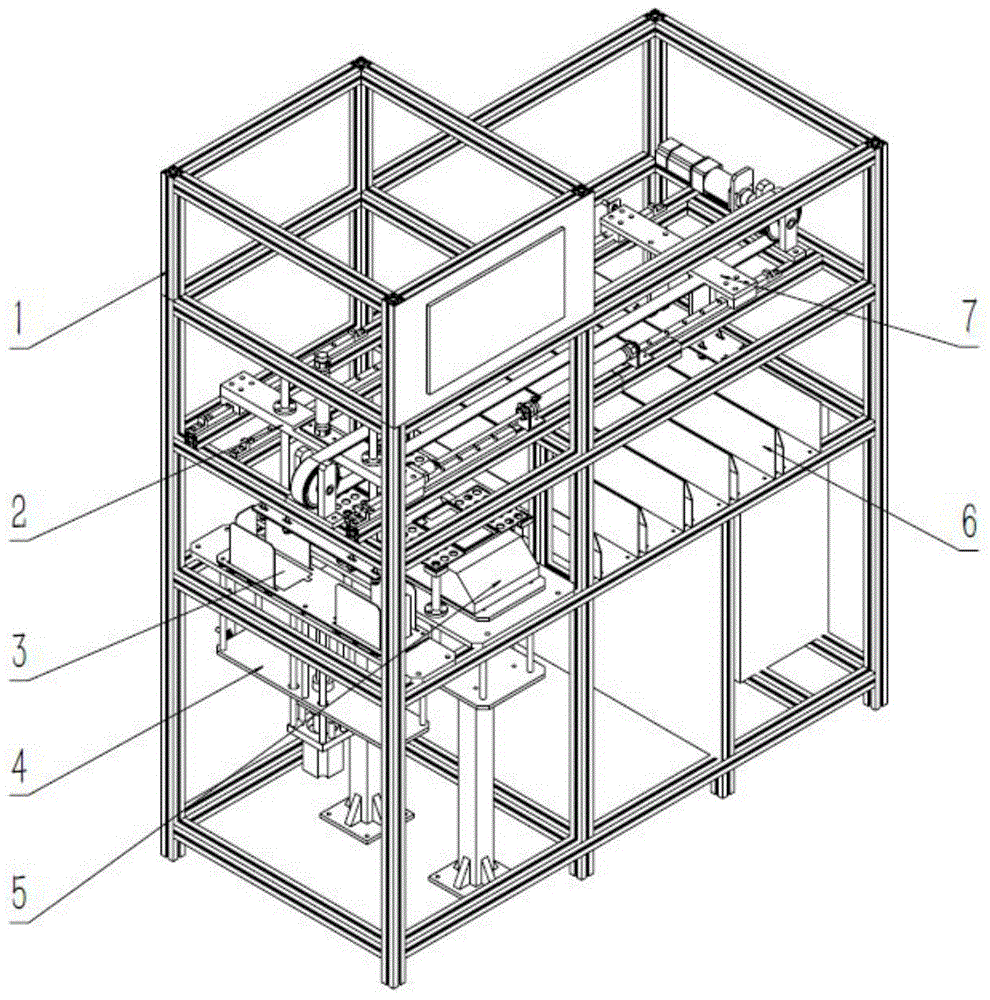

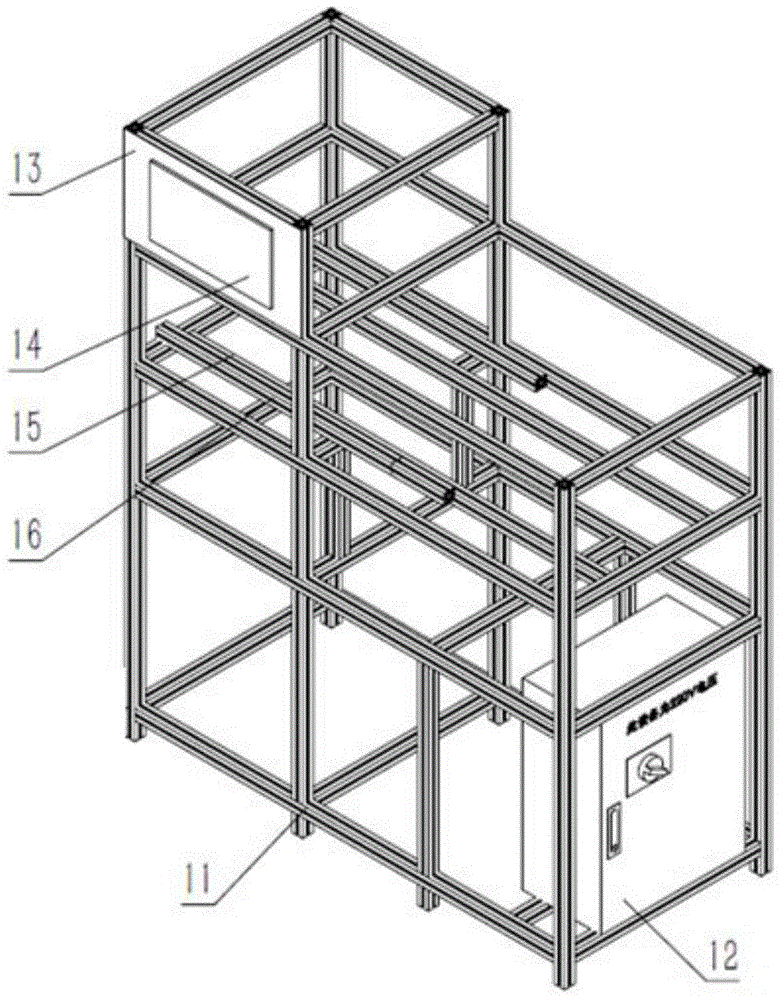

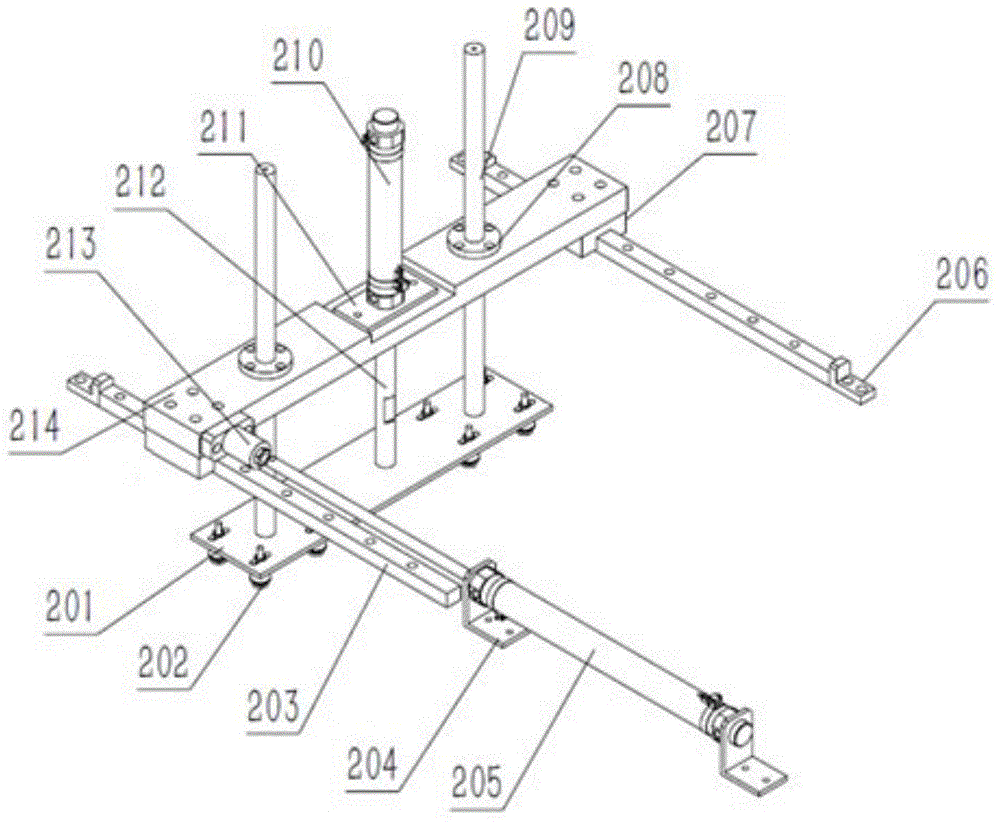

[0027] The lithium battery pole piece automatic weighing sorting device (being called for short device of the present invention, see Figure 1-10 ) includes a pole piece continuous feeding mechanism 4, a pole piece retrieving and transporting mechanism 2, an pole piece automatic weighing mechanism 5, a pole piece unloading and transporting mechanism 7, a support frame assembly 1 and a bin assembly 6; the support frame assembly 1 (see figure 2 ) includes a support frame 11, a control cabinet 12, a man-machine interface fixing plate 13, a man-machine interface 14, a linear guide rail fixed beam 16 at the feeding place and a linear guide rail fixed beam 15 at the unloading place, and the support frame 11 is a four-story building type The frame structure is connected by rectangular aluminum profiles; the control cabinet 12 is fixed to the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com