A high-precision square wire torque forming device

A molding device, high-precision technology, applied in the fields of medical science, dentistry, orthodontics, etc., can solve the problems of prolonging the treatment time of patients, poor clinical application effect, difficult torsion and bending of square wire, etc., to solve the problem of square wire springback Problems, good clinical application effects, and low operational skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

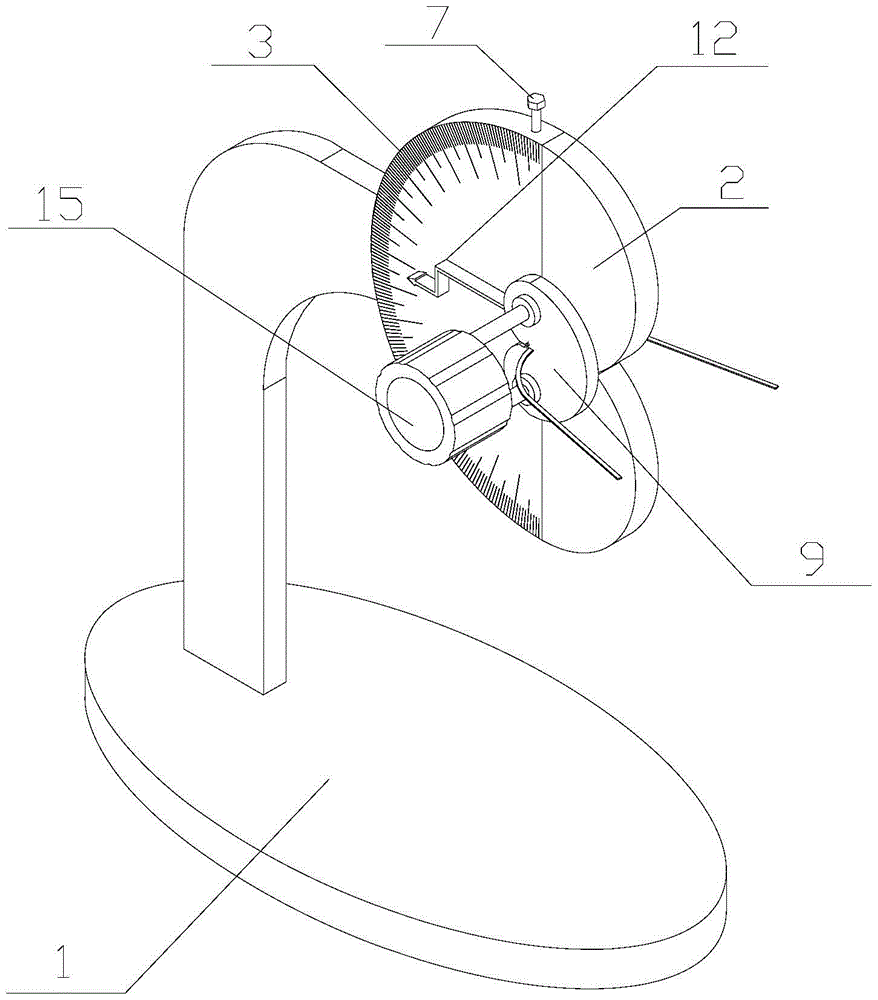

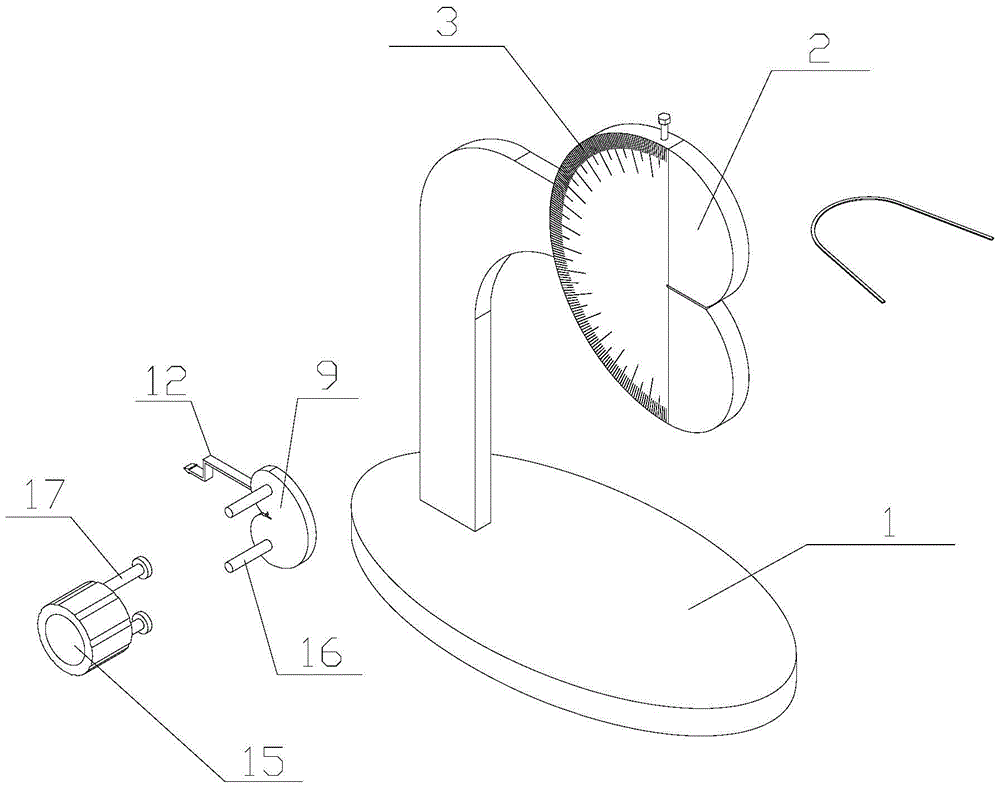

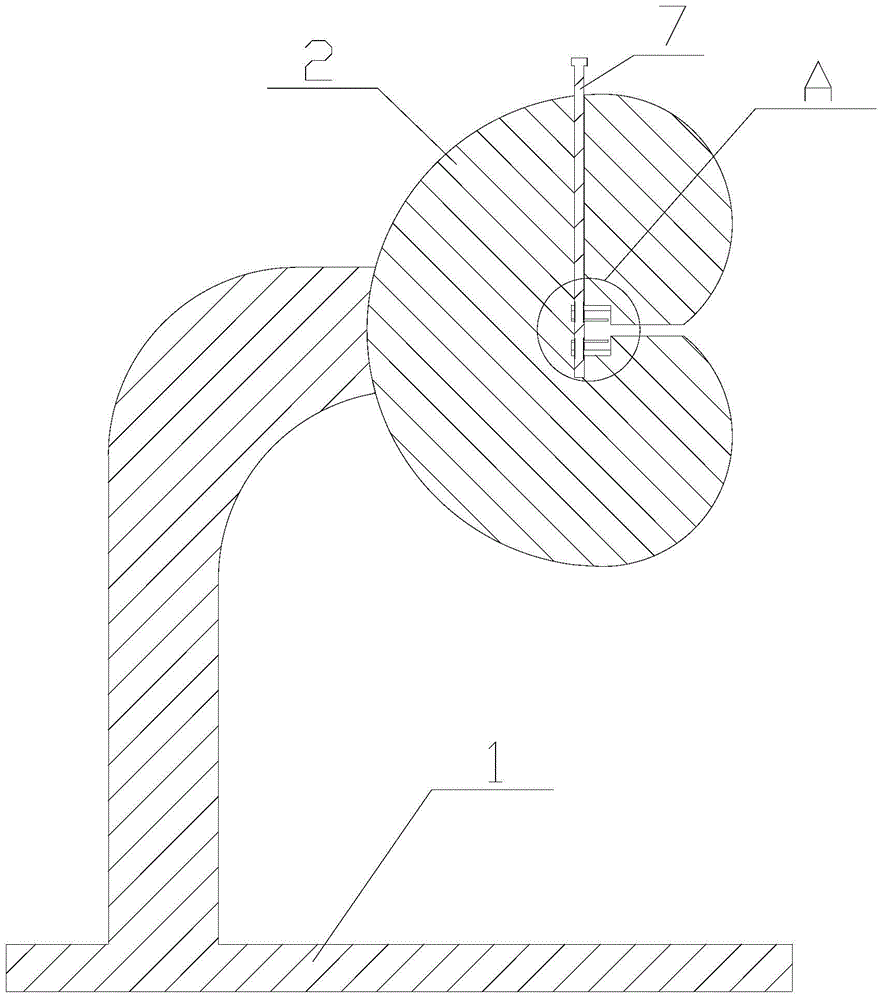

[0035] With reference to the accompanying drawings: this high-precision square wire torque forming device in the present embodiment includes a workbench 1, a torque scale plate 2 is installed on the workbench 1, and both left and right surfaces of the torque scale plate 2 are A scale 3 for displaying the angle is provided, and the scale 3 is located on one side of the torque scale plate 2, and the other side of the torque scale plate 2 is provided with a groove-4 for allowing the square wire to enter the torque scale plate 2, and the torque scale plate The center of the plate 2 is provided with a passage 5 for accommodating the square wire, the passage 5 communicates with the groove 4, and the top of the torque scale plate 2 is provided with a passage 6 communicating with the passage 5. Bolts 7 for fixing the square wires in the opening 5 are installed in the groove 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com