System and method for automatically generating shirt patterns

An automatic generation and shirt technology, applied in the direction of sewing tools and other directions, can solve the problem that the clothing CAD board system relies on user experience, professional level and subjective thinking, etc., to expand the application coverage, shorten the development cycle, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

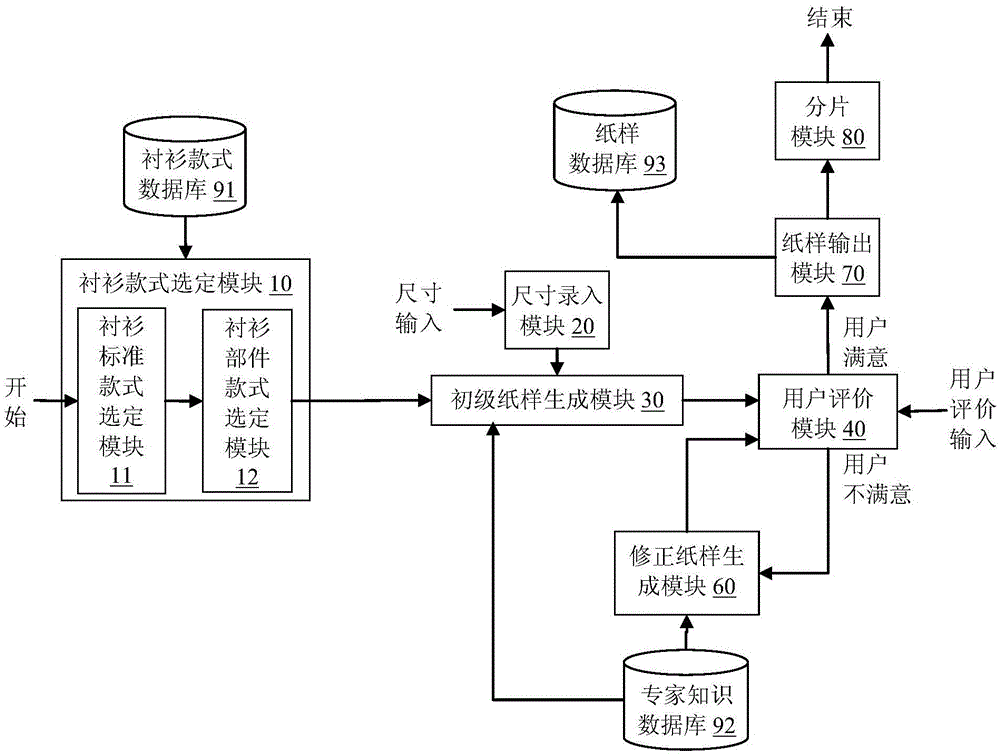

[0056] Such as figure 1 , the present invention proposes a shirt pattern automatic generation system, which includes a shirt style selection module 10, a size entry module 20, a primary pattern generation module 30, a user evaluation module 40, a corrected pattern generation module 60, a pattern output module 70, a shirt Style database 91 and expert knowledge database 92, shirt style selection module 10 can comprise shirt standard style selection module 11 and shirt parts style selection module 12 again, shirt style database 91 comprises shirt standard style database and shirt parts style database, wherein :

[0057] The shirt standard style selection module 11 is used for the user to select a shirt standard style based on the shirt standard style database;

[0058] The shirt part style selection module 12 is used for the user based on the shirt part style database, on the basis of the shirt standard style selected by the user through the shirt standard style selection module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com