Rope winch

A technology of winches and rope drums, which is applied in the field of lifting device winches, and can solve problems such as restrictions and large lateral force of rope loops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

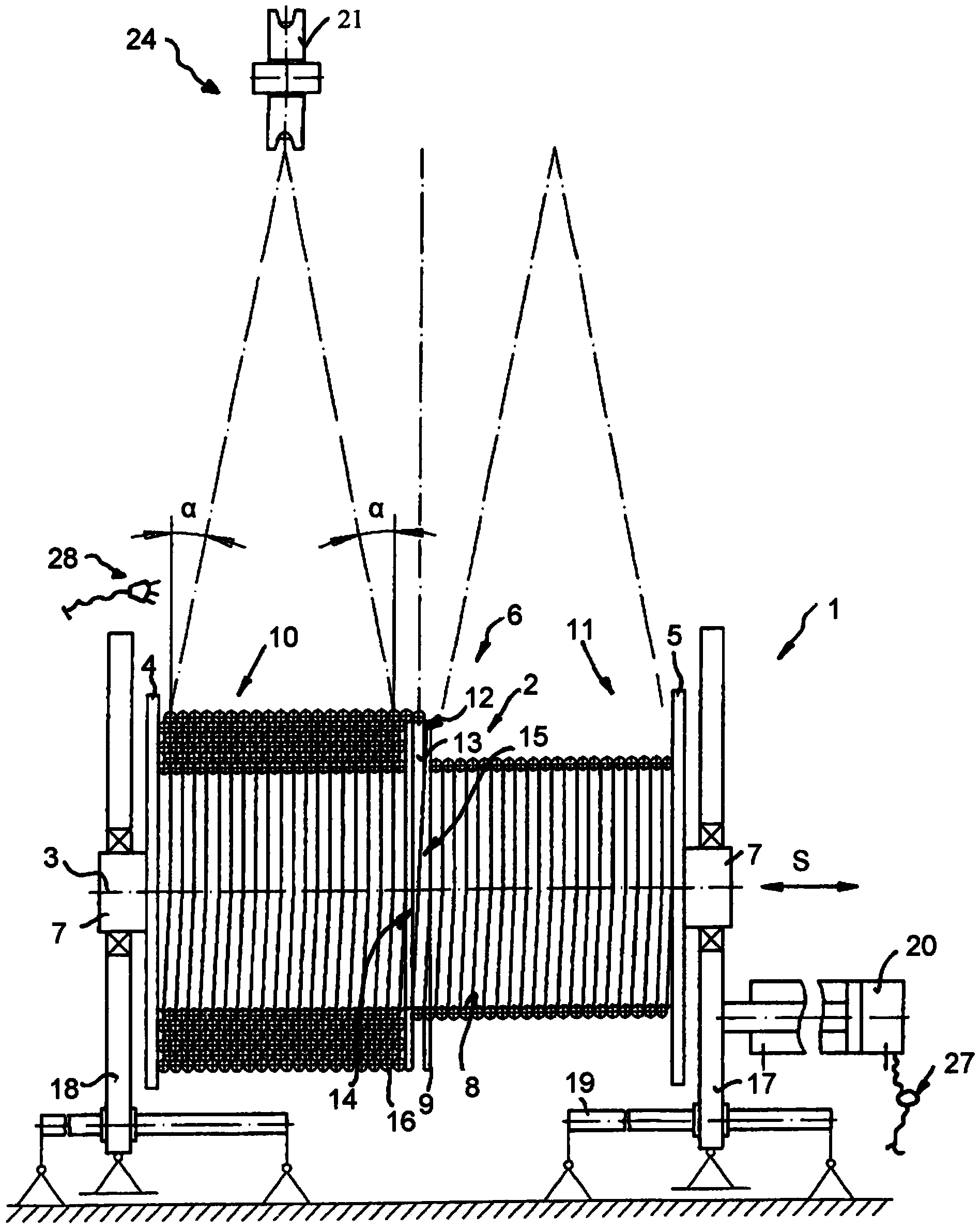

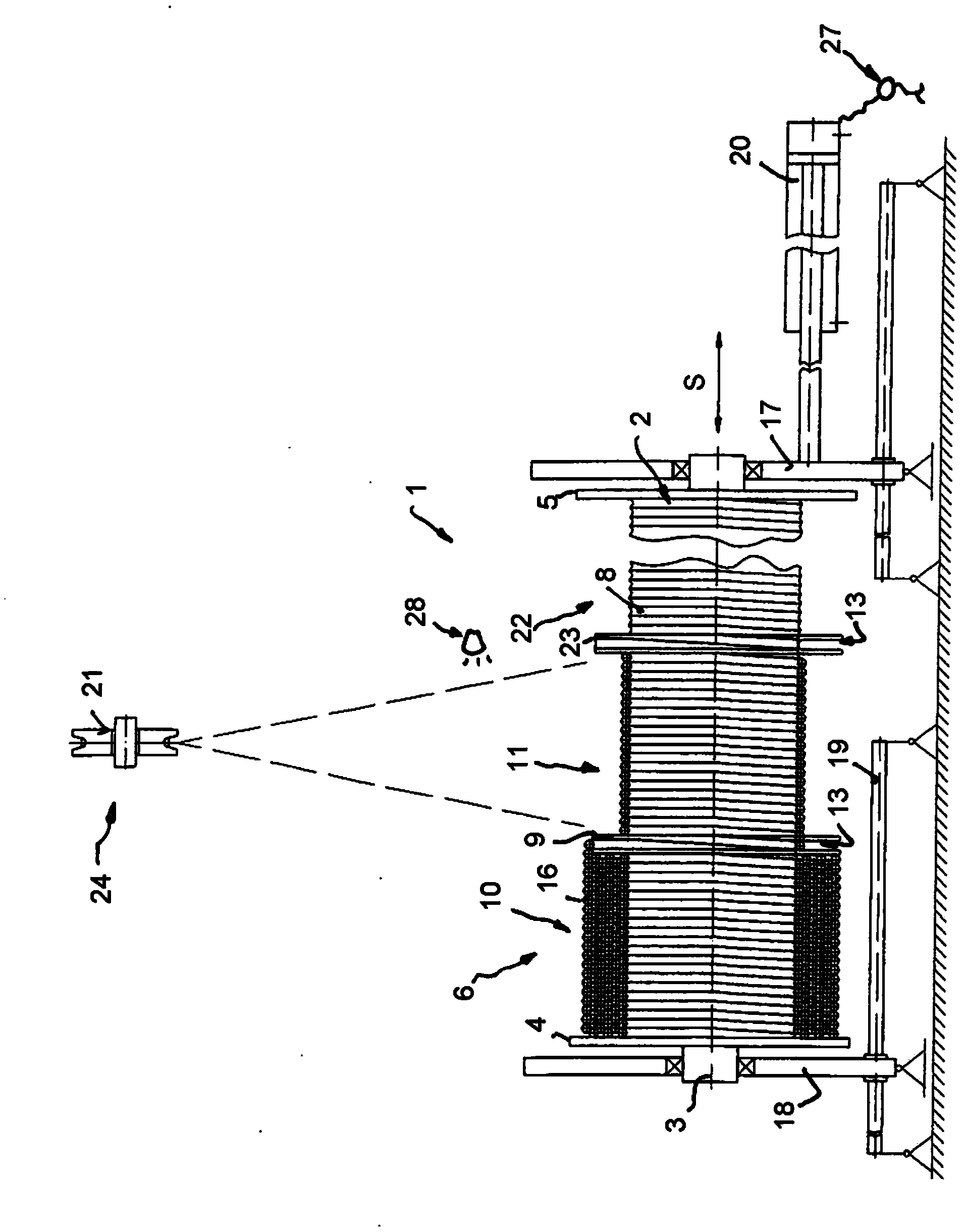

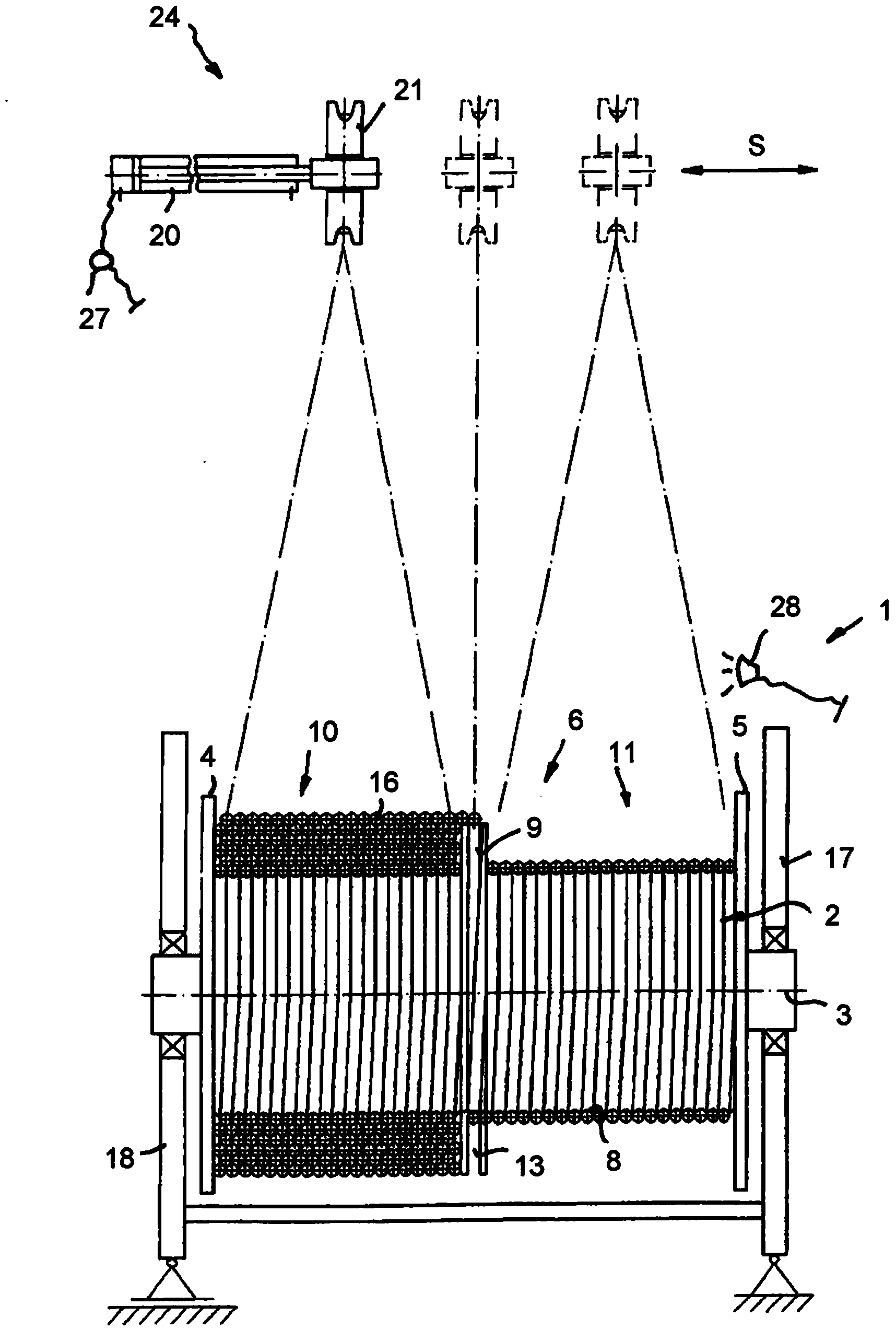

[0042] The winch 1 as shown in the figure comprises a substantially cylindrical rope drum 2, two flat retaining rings 4, 5 extending radially along the axis of rotation 3 of the rope drum are arranged on both ends of the rope drum, The winding area 6 of the rope drum 2 is defined between the flat retaining rings. In a manner known per se, the bearing end and / or the drive end 7 in the form of an axially protruding shaft end can be arranged on the rope drum 2, and the winch 1 can be mounted together with them on a lifting device such as a crane and as follows Supported longitudinally as explained above.

[0043] Such as figure 1 As shown, the peripheral surface of the rope reel 2 is equipped with a rope groove 8, and the rope groove extends helically outside the rope reel 2 in a threaded form to guide the rope to be wound on the rope reel 2, specifically the first rope. layer.

[0044] Such as figure 1 As shown, the winding area 6 of the rope drum 2 is divided into two sub-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com