Concrete stairs with hoisting seats and connecting pieces

A hoisting seat, concrete technology, applied in the directions of stairs, treads and vertical plate units, etc., can solve the problems of low construction efficiency, poor earthquake resistance, difficult alignment of connections, etc., and achieves good overall structure stress, good overall stress, Easy and fast connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

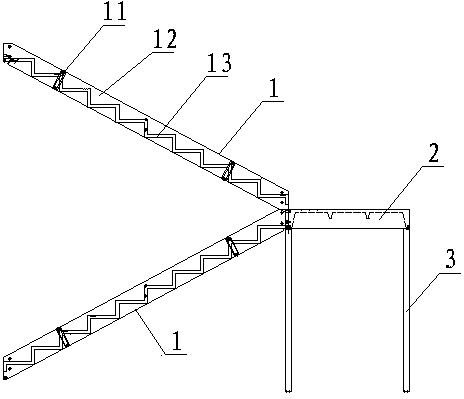

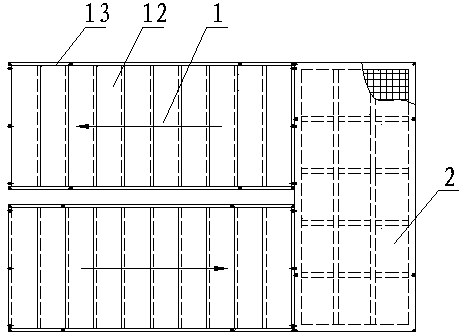

[0018] Such as figure 1 , figure 2 As shown, a concrete staircase with a sling 11 and connectors includes a step 1 and a platform 2 .

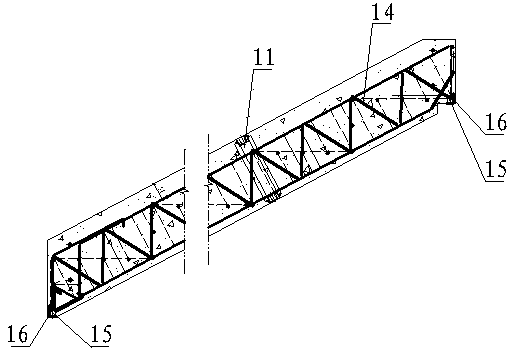

[0019] The step 1 is composed of a side plate 12 and a step plate 13 . Such as Figure 4 As shown, the ladder plate 13 is a reinforced concrete structure, and the reinforced mesh 17 is formed by weaving steel bars with smaller diameters in a multi-step shape. Such as image 3 As shown, the side plate 12 is a reinforced truss concrete structure, and the reinforced truss 14 is formed by weaving and welding steel bars with smaller diameters according to the shape of the truss. The steel bar trusses 14 are vertically welded on both sides of the steel mesh 17, and the two are firmly welded into one, and then put into the mold of the step 1, and the step 1 is formed by pouring concrete.

[0020] Such as image 3 , Figure 4 As shown, the threaded connecting pipes 15 with standard modulus spacing are pre-embedded in the ladder plate 13 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com