A Model Rope Support System Realizing Virtual Flight in Wind Tunnel

A technology for supporting systems and aircraft models, applied in the field of aircraft models to achieve the effects of improving measurement accuracy, increasing usable value, and being easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

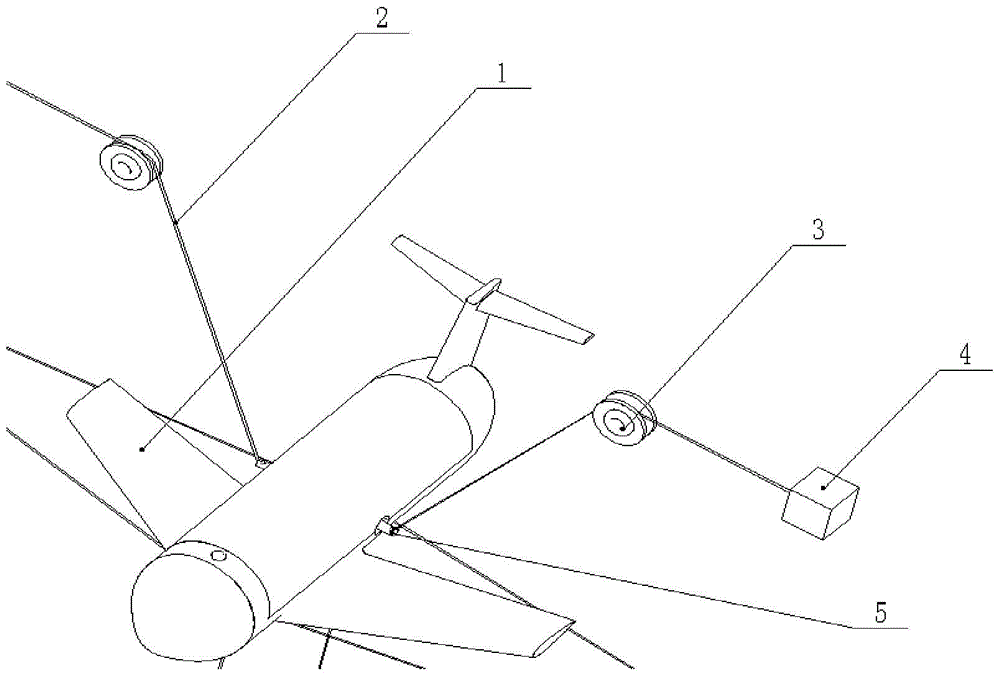

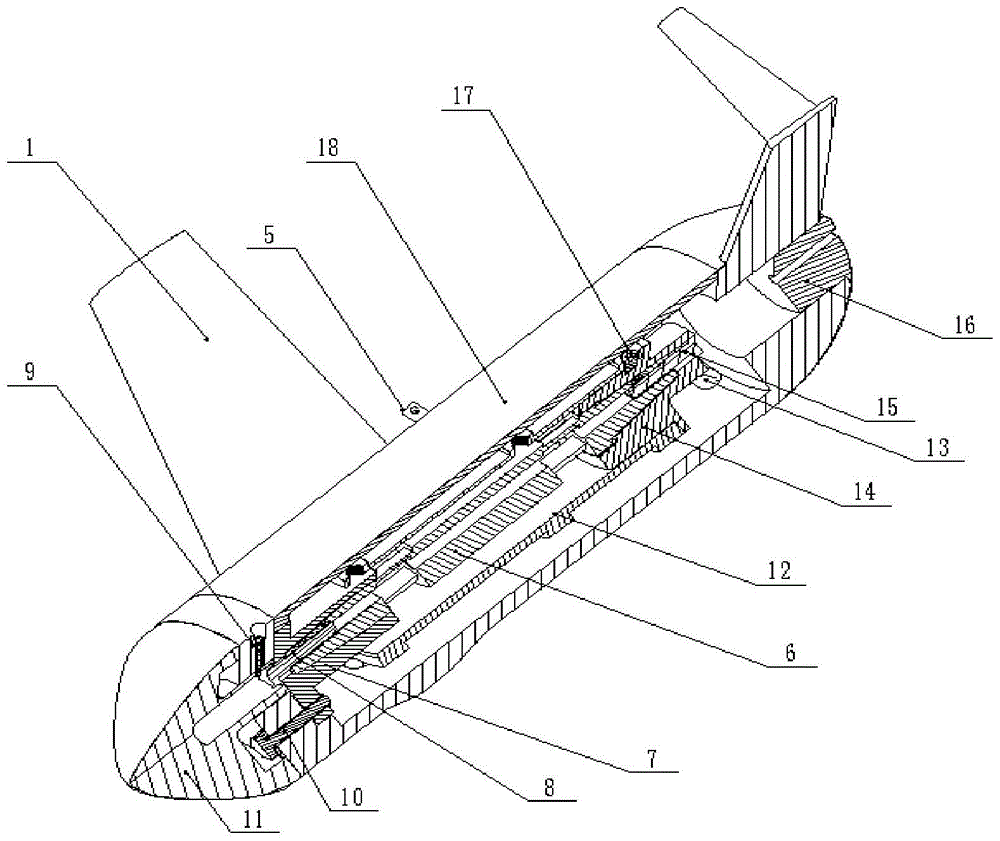

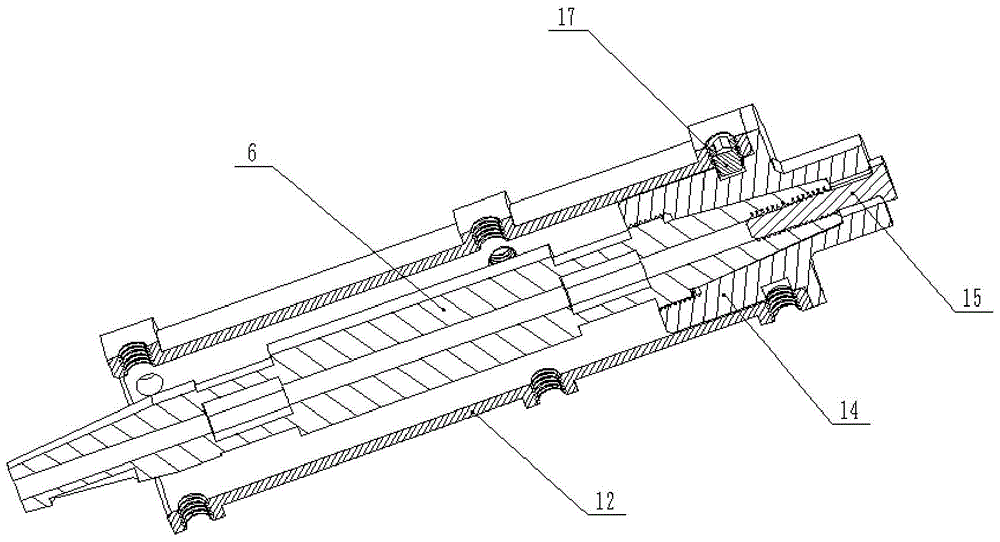

[0024] The embodiment of the present invention is provided with aircraft model 1, rod type six-component force balance 6, front taper sleeve 7, rear taper sleeve 14, sleeve 12 and pole 5, and aircraft model 1 is pulled and suspended by traction rope 2, and traction rope 2 One end is connected to winch motor assembly 4 by pulley 3, and the other end of traction rope 2 is connected with strut 5, is used for suspending and supporting aircraft model 1, and rod type six-component force balance 6 is located in aircraft model 1, and rod type six The force component balance 6 is coaxial with the aircraft model 1, the front end of the rod-type six-component force balance 6 is connected with the front cone sleeve 7 through 8, and the rear end of the rod-type six-component force balance 6 is connected with the rear cone sleeve 14 through a bolt 15, and the sleeve The cylinder 12 is fixedly connected to the rear taper sleeve 14 through bolts 17, the sleeve 12 is installed parallel to the r...

Embodiment 2

[0032] Figure 4 It is a schematic diagram of Embodiment 2 of the present invention. The installation and fixing methods of the airplane model and the rod-type six-component force balance assembly are the same as in Embodiment 1. combine Figure 5 Example cross-sectional view with Figure 6 It can be seen that the difference between embodiment 2 and embodiment 1 is that there is no tail plug, and the rear taper sleeve 14 located at the rear end of the balance is extended with an extended hollow pipe 19 extending out of the tail. Some small poles 5 are arranged on the prolongation hollow pipe 19, are used for tying the traction rope.

[0033] Embodiment 2 is an extension of the application of Embodiment 1. Different embodiments can be adopted according to the aerodynamic layout of the model appearance and the test purpose requirements, or the plug 16 of embodiment 1, or the extended hollow tube 19 added in embodiment 2, to change the layout of the rope system, thereby chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com